eBook - ePub

Global Regulatory Issues for the Cosmetics Industry

Karl Lintner

This is a test

Compartir libro

- 250 páginas

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

eBook - ePub

Global Regulatory Issues for the Cosmetics Industry

Karl Lintner

Detalles del libro

Vista previa del libro

Índice

Citas

Información del libro

This volume examines regulatory issues of ingredients, manufacturing, and finished products, as well as claim substantiation, packaging, and advertising. A chapter on Chinese regulations will be one of the first about this country to be published in book form.• Includes a regulatory map of India and China • Global IP protection strategies • REACH and European Regulatory standards • "Green chemistry" in relation to cosmetics and regulation

- Simplifies global regulations for anyone exporting cosmetics

- Excellent reference not only for manufacturing and marketing, but for legal departments and packaging as well

- Describes how to develop a global regulatory strategy

Preguntas frecuentes

¿Cómo cancelo mi suscripción?

¿Cómo descargo los libros?

Por el momento, todos nuestros libros ePub adaptables a dispositivos móviles se pueden descargar a través de la aplicación. La mayor parte de nuestros PDF también se puede descargar y ya estamos trabajando para que el resto también sea descargable. Obtén más información aquí.

¿En qué se diferencian los planes de precios?

Ambos planes te permiten acceder por completo a la biblioteca y a todas las funciones de Perlego. Las únicas diferencias son el precio y el período de suscripción: con el plan anual ahorrarás en torno a un 30 % en comparación con 12 meses de un plan mensual.

¿Qué es Perlego?

Somos un servicio de suscripción de libros de texto en línea que te permite acceder a toda una biblioteca en línea por menos de lo que cuesta un libro al mes. Con más de un millón de libros sobre más de 1000 categorías, ¡tenemos todo lo que necesitas! Obtén más información aquí.

¿Perlego ofrece la función de texto a voz?

Busca el símbolo de lectura en voz alta en tu próximo libro para ver si puedes escucharlo. La herramienta de lectura en voz alta lee el texto en voz alta por ti, resaltando el texto a medida que se lee. Puedes pausarla, acelerarla y ralentizarla. Obtén más información aquí.

¿Es Global Regulatory Issues for the Cosmetics Industry un PDF/ePUB en línea?

Sí, puedes acceder a Global Regulatory Issues for the Cosmetics Industry de Karl Lintner en formato PDF o ePUB, así como a otros libros populares de Business y Industria tessile e della moda. Tenemos más de un millón de libros disponibles en nuestro catálogo para que explores.

Información

Categoría

BusinessCategoría

Industria tessile e della modaChapter 1 Green Chemistry: Foundations in Cosmetic Sciences

Amy S. Cannon 1 , John C. Warner 2

1 Beyond Benign, Woburn, MA, USA

2 Warner Babcock Institute for Green Chemistry, Woburn, MA, USA

1.1 Introduction

The manufacturing industries have been experiencing increasing pressure from regulatory and government agencies and society in general on issues concerning human health and the environment. While sustainability in its “big picture” ideals are easy for individuals to understand, it is at the practical level that clarity is less forthcoming. As corporations strive to meet various sustainability objectives within operations such as recycling and energy audits, fundamental incorporation at the most basic levels often do not exist. Sustainability should include every aspect of an industry's operations. Green chemistry speaks to the chemists and materials scientists to incorporate sustainable principles into their practices of creating products and developing processes. The field of green chemistry, since its beginnings in the early 1990s, has been growing in the scientific community at an ever-increasing rate. What began as a science around synthetic organic transformations has expanded to incorporate literally every aspect of chemistry, chemical engineering, and manufacturing sciences.

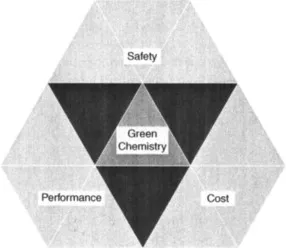

In the mid-1990s, the U.S. Environmental Protection Agency (EPA) began an awards program called the Presidential Green Chemistry Challenge Awards [1]. Each year five awards are given out to small and large businesses and academics for technologies that demonstrate the principles of green chemistry and that are also practical and can be commercialized. Green chemistry at its roots is about “real world” solutions to pollution prevention. For a technology to be successful in this awards program, and in fact to be considered “green chemistry,” it is not sufficient for the technology to be merely more benign than alternative technologies, it must also be viable in the marketplace. For a green chemistry technology to be viable in a competitive marketplace, it must satisfy two additional criteria in addition to product safety (Figure 1.1). It must demonstrate superior product performance; for example, environmentally benign cleaners that do not clean will not be desirable. It must also demonstrate appropriate economics. Society has demonstrated its unwillingness to pay a premium for environmentally benign technology. Adding these new criteria to product development is far from an easy task. Yet scientists in industry and academia have risen to the challenge and the more than 60 award winners of the Presidential Green Chemistry Challenge Awards program are testament to the ingenuity and innovation being applied.

Figure 1.1 Three requirements for green chemistry technologies.

Interestingly, when one reviews a list of the Presidential Green Chemistry Challenge Award winners, one finds a scarcity of any technologies that could be classified as belonging wholly to the cosmetics and personal care industry. However, a review of the nomination packages shows that there are very few proposals being submitted from the cosmetics and personal care industry. This is not to say that some green chemistry is not already happening in this industry, but certainly there is a great deal of opportunity.

1.2 Green Chemistry

Green chemistry is a set of principles that speak to the design scientist at the earliest part of a product development program. It incorporates downstream implications at the fundamental molecular level. By anticipating potential problems around scale-up associated with regulatory and toxicological issues, it is possible to not only reduce costs from a variety of internalized and externalized sources but also streamline operations by increasing efficiency and time to market. These principles were published in 1998 in the book titled Green Chemistry Theory and Practice [2].

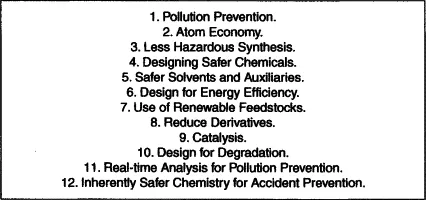

This book is a testament to the concerns of regulatory issues in the cosmetics and personal care industries. This chapter will discuss the twelve principles of green chemistry in the context of the cosmetics and personal care industries and how the concerns can be addressed at a fundamental level (Figure 1.2). While all the examples presented in this chapter may not be directly extracted from technologies immediately recognizable as being from this industry sector, it is hoped that they are similar enough to provide relative illustrative examples.

Figure 1.2 The twelve principles of green chemistry [2].

1.3 The Twelve Principles of Green Chemistry

Principle 1: Pollution Prevention. It is better to prevent waste than to treat or clean up waste after it is formed.

The first principle is merely a technical restatement of the old adage “a pinch of prevention is worth a pound of cure.” It focuses on looking at the materials flow in a product life cycle, with an eye toward reducing waste before it is ever created, recognizing the costs associated with disposal, cleanup, and remediation. When one considers the ethical and economic implications of using hazardous materials, it becomes immediately obvious that a safer, nontoxic technology (with identical product performance and economics) will always be superior in the marketplace. The economics and product performance is only part of the story. One need only pick up a newspaper, turn on the radio, or watch television to witness the explosion of environmental consciousness in every aspect of society. The demands by consumers for “sustainable” products are only going to increase in the years to come.

Pollution prevention is best addressed by creating technologies and products that reduce waste at the very beginning stages of their life cycles. Countless examples are testament to this principle and many speak to the heart of the environmental movement. Environmental disasters are far too common in our history. And, the cleanup is unfortunately quite costly. In the United States, the EPA estimates that nearly $6.5 billion has been spent toward their brownfield initiative since its inception in 1995 [3]. It is estimated that the initiative involves nearly 450,000 brownfield sites throughout the United States. It is evident that it is better to have not created this waste rather than spend billions of dollars for cleanup after the fact.

Principle 2: Atom Economy. Synthetic methods should be designed to maximize the incorporation of all materials used in the process into the final product.

A typical product life cycle begins with the extraction of raw materials from the earth, followed by the functionalizing of the raw materials into useful feedstock chemicals that can be transformed into the various chemical products that we require for making products. The synthesis of the chemical products involves the use of various reagents in order to create the desired product. Many reagents are used to perform a specific function on the molecule, but are not actually incorporated into the product. The reagents that are not incorporated into the product typically result in waste in a chemical process.

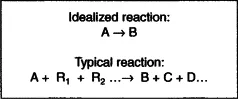

Throughout the history of chemistry, the quantitative success of a chemical transformation has typically focused on the concept of product yield. This number is based on the number of grams of products synthesized divided by the number of yields theoretically possible. While this measure provides some insight into the productivity of a chemical reaction, or series of reactions, much information is lost. Many synthetic transformations available in the chemist's toolbox do not merely follow the simple description of compound A is converted to compound B (Figure 1.3). More often than not, these transformations are far more complex with a number of reactants coming together to form a number of products (Figure 1.3). While the desired product may be obtained in high yield, it is possible and in fact often the case that along with the desired product an equivalent amount of some other anticipated by-product is formed.

Figure 1.3 An idealized versus a typical synthetic transformation. A: Starting material; B: Product; R: Reagent; C, D: Coproducts or by-products.

The atom economy of a reaction is based on a calculation developed by Barry Trost [4]: the ratio of the molecular weight of the atoms used to make a product divided by the molecular weight of all the reagents and starting materials used to make the product. It is a simple measure of the amount of waste created in a chemical process based on the atoms used in a process. This principle speaks to developing molecular transformations that incorporate a maximum number of atoms into the final product thus minimizing the atoms that appear as waste.

Principle 3: Less Hazardous Synthesis. Wherever practicable, synthetic methodologies should be designed to use and generate substances that possess little or no toxicity to human health and the environment.

It is often overlooked that the manufacturing pathway to synthesize a product ultimately may in fact go through a series of chemical intermediates.

This principle seeks to minimize the hazard associated with these intermediates. It is important to make the distinction that this principle is focused on materials that, in a perfect world, should not appear in the product. But, when considering worker exposure and the other associated costs related to disposal and hazardous materials, this is extremely important. Reducing the hazards associated with the way a product is made can drastically reduce worker liabilities and contribute toward worker health and safety.

In a typical manufacture of a product, the final step before packaging involves formulation. Formulation is the assembly of various materials acquired internally or from external vendors. It is important to recognize that these ingredient materials are being synthesized somewhere, whether in-house or by the supplier. Some solutions to working with hazardous materials can seem to be successful from the perspective of the formulator; it is in fact possible that somewhere upstream hazardous materials are being used and generated. In a complete life cycle analysis a “not-in-my-backyard” solution is not sufficient. Thus, it is important that the entire supply chain for a product be evaluated and optimized.

For example, an outside supplier typically supplies a plastic packaging material for most consumer products. There are several plastic types to choose from and they are often selected by their desired properties so as to contain the consumer product and retain its functionality. Many plastic materials are nontoxic to humans. However, the ways of manufacturing such plastic can be hazardous to the workers who operate and handle the materials during production. Therefore, it is important to reduce the hazard during the creation of such plastic materials.

One example where a plastic material was created that accomplished the task of reducing the hazard in a manufacturing setting is that of Cargill Dow's (now NatureWorks LLC) NatureWorks™ PLA process. In 2002, the company won the G...