![]()

CHAPTER 1

Risk Assessment of Plastic-based Food Contact Materials: Focus on Polyolefins

Fabio Testoni*a and Ines Mingozzi*a

a Basell Poliolefine Italia Srl, Italy, R&D PT&C (Process Testing and Characterization), Piazzale Donegani 12, 44122 Ferrara, Italy

*E-mail:[email protected], [email protected]The aim of this chapter is to describe and comment on analytical approaches for characterizing intentionally added substances (IASs) with specific migration limits (SMLs) and non-intentionally added substances (NIASs) present in polyolefins used in food contact applications. Current EU regulations require the monitoring of packaging material components that could migrate into food, to avoid possible safety and quality issues. Generally, an extraction step involving static headspace (SHS), dynamic headspace and solvent extraction is applied for this purpose. Mass spectrometry coupled with chromatography is the main technique that can provide quantification and identification in line with regulatory requirements. Also, flame ionization detection (FID) is widely used as it allows universal quantitation in many cases. The described techniques can be applied to most of the plastic materials used in food packaging. In this chapter, only polyolefin-based polymers are considered and examples are focused mainly on polypropylene (PP) and its copolymers.

1.1 Introduction

Polyolefins is a term indicating a class of polymers commonly used for, among other applications, food packaging.1 They are produced starting from one or more monomers, polymerization aids (catalysts, peroxides, etc.) and polymer production aids (i.e. in-process antistatic agents). Solvents can also be present. The resulting base polymer is then formulated with additives. Polymers in their final form (generally pellets, granules or flakes) are sold to converters to produce articles.

Monomer(s), additives, polymerization aids (PAs) and polymer production aids (PPAs) are considered intentionally added substances (IASs). Impurities within starting raw materials and reaction products from the manufacturing process (i.e. oligomers, additive by-products) are defined as non-intentionally added substances (NIASs) and are subjected to risk assessment, in addition to PAs and PPAs if not listed in EU or National Food Contact Regulations.

Regulation (EC) No. 1935/2004 of the European Parliament and of the Council of 27 October 2004 provides general principles of safety and inertness for all food contact materials (FCMs). In addition, EU Regulation No. 10/2011 as amended sets out rules for plastic materials in contact with food. EU Regulation No. 10/2011 describes requirements for migration tests. There are two types of limits: OML (overall migration limit) and SML (specific migration limit). OML is based on the total mass of substances that can migrate (gravimetric analysis), whereas SML is based only on quantification of one specific substance that can migrate into food.

EU Regulation No. 10/2011 is based on the principle of a “positive list” and Annex 1 contains the list of authorized chemicals (monomers, additives and certain PPAs). Some listed substances can have an SML. Other substances that are not required to be listed, such as PAs and NIASs, need to be risk assessed.

When a polymer is used for food contact applications, there are important material features that must be considered before approaching any further analytical challenge related to risk assessment:

- ODOUR: According to current regulation:2 “… any material or article intended to come into contact directly or indirectly with food must be sufficiently inert to preclude substances from being transferred to food in quantities large enough to endanger human health or to bring about an unacceptable change in the composition of the food or a deterioration in its organoleptic properties.” This means that it is necessary to monitor packaging material components that could migrate into food, deteriorating safety and quality, starting from a low molecular weight.

- NIASs: According to EFSA (European Food Safety Association),3 reaction products and impurities (NIASs) that are not included in the EU list of authorized substances in EU Regulation No. 10/2011 are required to be risk assessed, irrespective of their source or intended function. Oligomers are also considered as NIASs. Their identification and quantification are required for risk assessment by Art. 19 of EU Food Contact Regulations 10/2011/EC, specifically for those oligomers with molecular weight (MW) <1000 dalton (Da), as potential migrants of concern which, after transfer (migration) into food, may be physiologically resorbed after ingestion.

1.2 Evaluation of Analytical Approaches

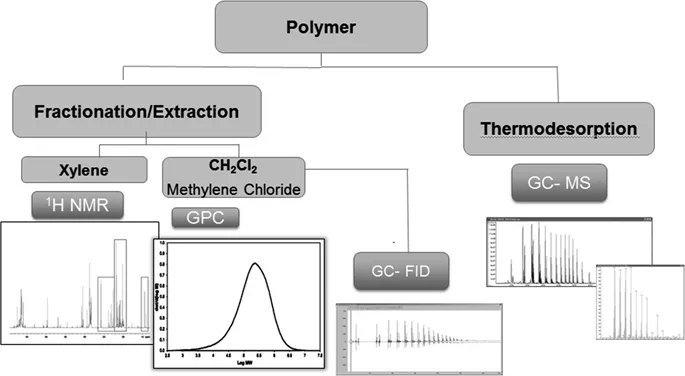

Polymer characterization usually consists of fractionation/extraction or thermal desorption. Fractionation/extraction can be carried out using different solvents and techniques. Aiming to investigate all the species present in an FCM, a combination of analytical methods is used. With polypropylene, a commonly used approach is the separation of the insoluble crystalline part (Xi) from the soluble atactic fraction and oils.4,5 Methylene chloride (CH2Cl2) is another solvent that is commonly used. The fractionated or extracted part can be analysed using different instrumental techniques: NMR (nuclear magnetic resonance), GPC (gel permeation chromatography), GC-FID (gas chromatography coupled with flame ionization detection), GC-MS (gas chromatography coupled with mass spectrometry), HPLC-MS or HPLC-DAD (high-performance liquid chromatography coupled with mass spectrometry or diode-array detection, respectively). The polymer as such can also be thermally desorbed and studied by GC-MS and GC-FID (see Figure 1.1).

Figure 1.1Polymer analytical approaches. PP case: fractionation, extraction, thermal desorption. Techniques involved are NMR, GPC and capillary GC.

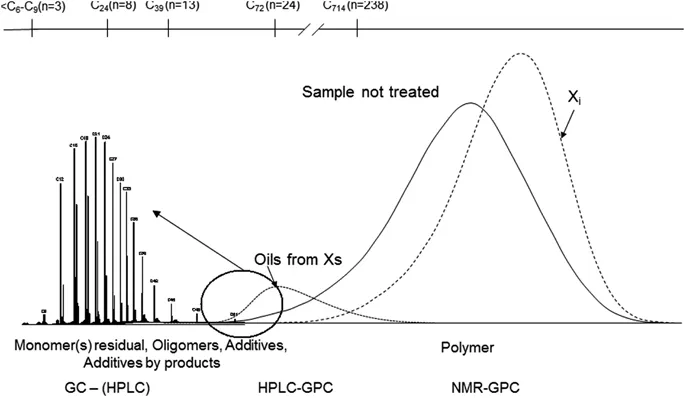

What emerges is a very complex matrix, with species covering a very wide MW range, starting from a few daltons (residual monomer) up to millions of daltons (high-MW polymers with high crystallinity), as shown in Figure 1.2. This scheme is characteristic and different for each individual polymer.

Figure 1.2Scheme of PP polymeric matrix profile, starting from monomer residual, passing through additives and oligomers, arriving at the crystalline fraction. Polymer oligomers are zoomed (circled zone) via GC. The upper scale roughly indicates the region for hydrocarbon clusters; n in parentheses indicates the degree of polymerization when propylene is concerned.

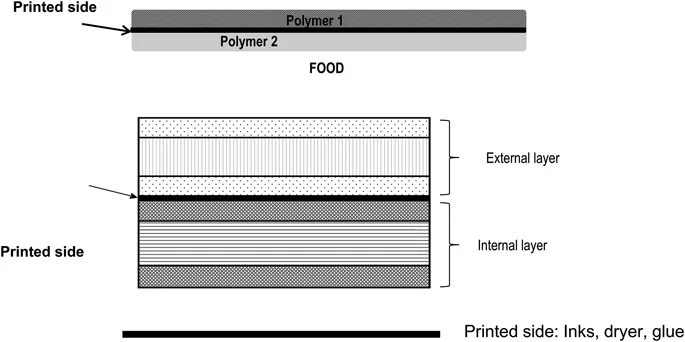

Considering a very common FCM, i.e. a printed film to wrap food, a deeper investigation reveals a very complicated situation (see Figure 1.3). At least four different polymers were used, laminated with a printed surface and glue.

Figure 1.3High end use film for food packaging: multi-layer laminated film with printed side and glue.

Analysis of a final item is very difficult and the result is a sum of the contributions from each individual layer component, including the printed layer (with or without paper, when present) and glue, and heating effects during extrusion/lamination. Moreover, it is worth remembering that each film layer can be formed by more than a single polymer.

Very complex matrices, due to different plastic materials and printing and lamination processes, are usually challenging to analyse if the whole production chain is unknown. The final item is analysed to characterize NIASs, but it would often be desirable to obtain more information about the origin of the NIASs.6

For the above reasons, to achieve a full characterization and understa...