Design and Construction of LNG Storage Tanks

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Design and Construction of LNG Storage Tanks

About this book

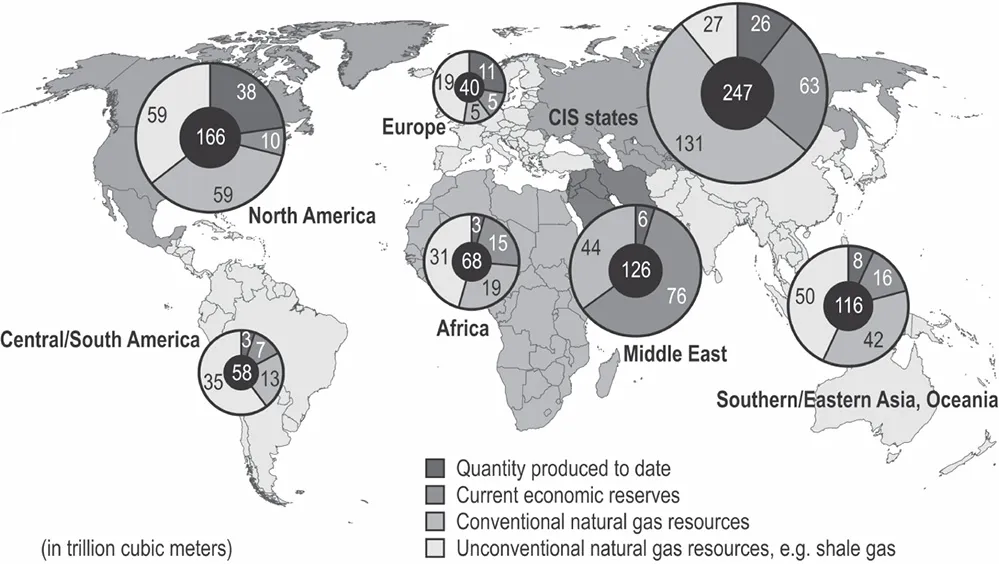

Worldwide, the use of natural gas as a primary energy source will remain vital for decades to come. This applies to industrialized, emerging countries and developing countries. Owing to the low level of impurities, natural gas is considered to be a climate-friendly fossil fuel because of the low CO2 emissions, but is at the same time an affordable source of energy.

In order to enable transport over long distances and oceans (and hence create an economic and political alternative to pipelines), the gas is liquefied, which is accompanied by a considerable reduction in volume, and then transported by ship. Thus, at international ports, many LNG tanks are required for temporary storage and further use. The trend towards smaller liquefaction and regasification plants with associated storage tanks for marine fuel applications has attracted new players in this market who often do not yet have the necessary experience and technical expertise. It is not sufficient to refer to all existing technical standards when defining consistent state-of-the-art specifications and requirements.

The switch to European standardisation has made it necessary to revise and adapt existing national codes to match European standards. Technical committees at national and international level have begun their work of updating and completing the EN 14620 series.

In the USA, too, the corresponding regulations are also being updated. The revision of American Concrete Institute standard ACI 376 Requirements for Design and Construction of Concrete Structures for the Containment of Refrigerated Liquefied Gases, first published in 2011, will be completed in the spring of 2019, and the final version, published in autumn 2019.

This book provides an overview of the state of the art in the design and construction of liquefied natural gas (LNG) tanks. Since the topic is very extensive and complex, an introduction to all aspects is provided, e.g. requirements and design for operating conditions, thermal design, hydrostatic and pneumatic tests, soil surveys and permissible settlement, modelling of and calculations for the concrete structure, and the actions due to fire, explosion and impact. Dynamic analysis and the theory of sloshing liquid are also presented.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

Reference

- 1 Flüchtige Zukunft. Wirtschaftswoche, No. 32, 2012, pp. 58–65.

2

History of Natural Gas Liquefaction

2.1 Industrialisation and Energy Demand

Table of contents

- Cover

- Table of Contents

- Editorial

- About the Author

- 1 Introduction

- 2 History of Natural Gas Liquefaction

- 3 Regulations and their Scope of Applicability

- 4 Definitions of the Different Tank Types

- 5 Performance Requirements and Design

- 6 Tank Analysis

- 7 Dynamic Analysis

- 8 Construction

- 9 Summary

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app