Food Packaging Materials

Testing & Quality Assurance

- 344 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Food Packaging Materials

Testing & Quality Assurance

About this book

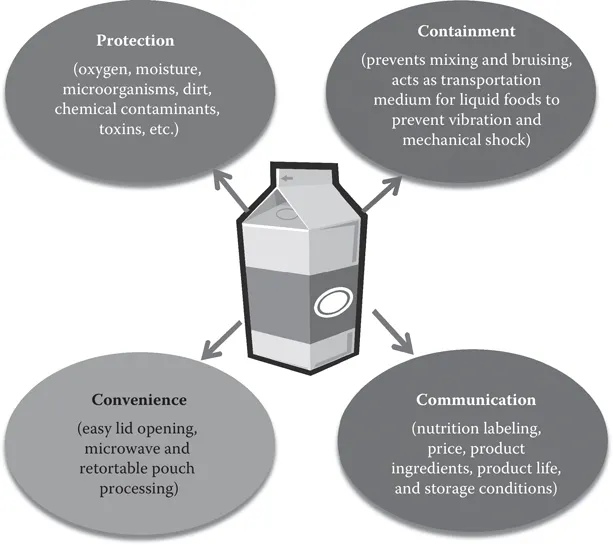

This book is arguably the first one focusing on packaging material testing and quality assurance. Food Packaging Materials: Testing & Quality Assurance provides information to help food scientists, polymer chemists, and packaging technologists find practical solutions to packaging defects and to develop innovative packaging materials for food products. Knowledge of packaging material testing procedures is extremely useful in the development of new packaging materials. Unique among books on packaging, this reference focuses on basic and practical approaches for testing packaging materials.

A variety of packaging materials and technologies are being used, with glass, paper, metal, and plastics as the most important groups of materials. Material properties such as mechanical and other physical properties, permeability, sealing, and migration of substances upon food contact are determining factors for food quality, shelf life, and food safety. Therefore, food packaging materials have to be tested to ensure that they have correct properties in terms of permeability for gases, water vapor, and contaminants; of mechanical and other physical properties; and of the thickness of main components and coating layers.

This book has been designed to shed light on food packaging material testing in view of packaging integrity, shelf life of products, and conformity with current regulations. This comprehensive book, written by a team of specialists in the specific areas of food packaging, package testing, and food contact regulations, deals with the problems in a series of well-defined chapters. It covers the relations between packaging properties and shelf life of products and describes testing methods for plastics, metal, glass, and paper, including the areas of vibration, permeation, and migration tests. It will be of benefit for students, scientists, and professionals in the area of food packaging.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

- Kraft paper: Natural brown, unbleached, bleached white, and heavy duty, this paper is used to fabricate bags and wrappings. It is the strongest paper and is used for packaging flour, sugar, and dried fruits and vegetables.

- Sulfite paper: This paper is glazed to improve its appearance, wet strength, and oil resistance. Sulfite paper is relatively lighter and weaker than kraft paper but has high print quality. It is often used with plastic or foil laminates to prepare packaging materials for biscuits and confectionery.

- Greaseproof paper: Offering resistance to oil but allowing moisture migration, greaseproof paper is commonly used to pack cookies, butter, oily foods, candies, and so forth.

- Glassine: This greaseproof paper has a high degree of smoothness and a glossy finish. It is commonly used for packaging biscuits, fats, fast foods, and so on.

- Parchment paper: Made from acid-modified cellulose to improve its air and moisture barrier properties, parchment paper is used for butter, lard, and fat packaging.

- Paperboard: Paperboard is available in several forms (white board, solid board, chip board, fiber board, and paper laminates) and is mainly used in secondary packaging to improve the handling and distribution of food products.

Table of contents

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Editors

- Contributors

- Chapter 1 Introduction: Food Packaging Materials

- Chapter 2 Shelf Life of Packed Food and Packaging Functionality

- Chapter 3 Testing of Physical, Optical, Electrical, Thermal, and Rheological Properties for Plastic Packaging Materials

- Chapter 4 Testing of Mechanical Properties for Plastic Packaging Materials

- Chapter 5 Permeation Testing of Synthetic Polymers

- Chapter 6 Testing Glass as a Food Packaging Material

- Chapter 7 Metal Packaging: Testing and Quality Assurance

- Chapter 8 Testing of Paper as Packaging Material for Food Industry

- Chapter 9 Testing and Quality Assurance of Bioplastics

- Chapter 10 Shock and Vibration Testing of Packaging Materials

- Chapter 11 Testing Migration from Food Packaging Materials

- Chapter 12 Food Package Testing Authorities and Regulations

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app