Recrystallization and Related Annealing Phenomena

- 734 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Recrystallization and Related Annealing Phenomena

About This Book

Recrystallization and Related Annealing Phenomena, Third Edition, fulfills the information needs of materials scientists in both industry and academia. The subjects treated in the book are all active research areas, forming a major part of at least four regular international conference series. This new third edition ensures the reader has access to the latest findings, and is essential reading to those working in the forefront of research in universities and laboratories.

For those in industry, the book highlights applications of the research and technology, exploring, in particular, the significant progress made recently in key areas such as deformed state, including deformation to very large strains, the characterization of microstructures by electron backscatter diffraction, the modeling and simulation of annealing, and continuous recrystallization.

- Includes over 50% of new, revised, and updated material, highlighting the significant recent literature results in grain growth in non-crystallizing systems, 3D characterization techniques, quantitative modeling techniques, and all-new appendices on texture and measurements

- Contains synthesized, detailed coverage from leading authors that bridge the gap between theory and practice

- Includes a critical level of synthesis and pedagogy with an authored rather than edited volume

Frequently asked questions

Introduction

Abstract

Keywords

1.1. Annealing of a Deformed Material

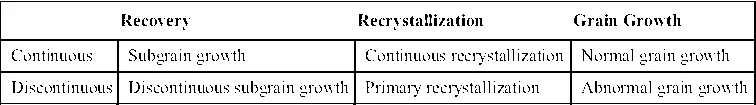

1.1.1. Outline and Terminology

| Recovery | Recrystallization | Grain Growth | |

| Continuous | Subgrain growth | Continuous recrystallization | Normal grain growth |

| Discontinuous | Discontinuous subgrain growth | Primary recrystallization | Abnormal grain growth |

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface to the First Edition

- Preface to the Second Edition

- Preface to the Third Edition

- Acknowledgments

- Symbols

- Abbreviations

- Chapter 1. Introduction

- Chapter 2. The Deformed State

- Chapter 3. Deformation Textures

- Chapter 4. The Structure and Energy of Grain Boundaries

- Chapter 5. Mobility and Migration of Boundaries

- Chapter 6. Recovery After Deformation

- Chapter 7. Recrystallization of Single-Phase Alloys

- Chapter 8. Recrystallization of Ordered Materials

- Chapter 9. Recrystallization of Two-Phase Alloys

- Chapter 10. The Growth and Stability of Cellular Microstructures

- Chapter 11. Grain Growth Following Recrystallization

- Chapter 12. Recrystallization Textures

- Chapter 13. Hot Deformation and Dynamic Restoration

- Chapter 14. Continuous Recrystallization During and After Large Strain Deformation

- Chapter 15. Control of Recrystallization

- Chapter 16. Computer Modeling and Simulation of Annealing

- Appendix 1. Texture

- Appendix 2. The Measurement of Recrystallization

- References

- Index