eBook - ePub

Woodworker's Guide to Veneering & Inlay (SC)

Techniques, Projects & Expert Advice for Fine Furniture

This is a test

- 250 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Woodworker's Guide to Veneering & Inlay (SC)

Techniques, Projects & Expert Advice for Fine Furniture

Book details

Book preview

Table of contents

Citations

About This Book

With this complete resource from professional furniture-maker and veneer specialist Jonathan Benson, you'll learn how to re-create the beauty of exotic wood with veneer and in-lays. A series of step-by-step exercises will take you through all the techniques and culminate in four beautiful finished pieces: a dining room table, a wall mirror with shelf, a marquetry picture, and a parquetry design. Also included is a complete troubleshooting section for repairs and problems.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Woodworker's Guide to Veneering & Inlay (SC) by Jonathan Benson in PDF and/or ePUB format, as well as other popular books in Tecnología e ingeniería & Oficios técnicos y manufactureros. We have over one million books available in our catalogue for you to explore.

Information

CHAPTER 1

Veneering Then & Now

A wood veneer is an attractive but thin slice of wood that can be glued onto a furniture surface or wall panel, creating a rich look for very little expenditure of expensive material. Veneering is an old process that has changed and developed along with advances in wood processing and cutting. Historically, veneer was used to decorate the very finest furniture; in recent times, it has also been used to disguise some of the worst. Today, it is still possible to produce very fine veneered furniture using basic woodworking tools.

Desert Sun Sideboard by Jonathan Benson combines vintage Brazilian rosewood, curly maple, and ebony veneers. The 36" x 62" x 22" sideboard was created using the simple tools and techniques covered in this book.

Historical background

Veneers have been used in woodworking for more than 5,500 years. Examples of veneered pieces dating back to at least 3500 BC have been discovered in the pyramids of ancient Egypt. Hieroglyphics and frescoes created around 1950 BC depict workers cutting, joining, and gluing down sheets of veneer using stones as weights for clamping. The veneers were cut with an adze, a tool resembling an ax with its blade turned perpendicular to the handle. This process produced veneers that were rough, uneven, and about ¼" thick.

As technology progressed, it became possible to make thinner veneers. In Roman times, an iron-bladed pit saw was used. One worker stood in a pit below a log while another worker stood above, each pulling opposite ends of a large saw. The Romans also developed smaller bow-type saws, which could be used by one or two people. Sawn veneers could be much thinner than adzed veneers, close to ⅛" thick. Like adzed veneers, these early sawn veneers remained uneven and required much leveling and smoothing to create an even surface. Because these processes were labor intensive, veneers could only be used in the highest applications.

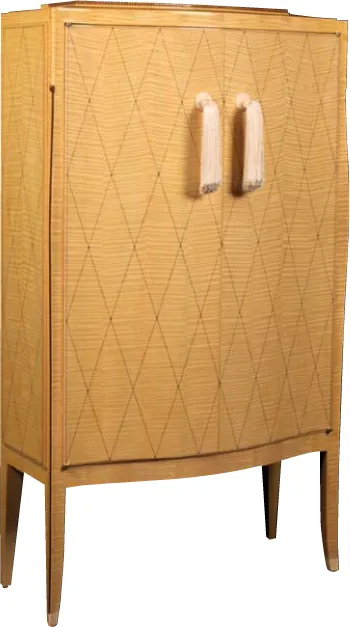

Figure 1-1. A 48" x 22" x 12" Art Deco chiffonier in curly maple is a classic 1930s Ruhlmann reproduction by Pollaro Custom Furniture Inc., Union, New Jersey. (Photo courtesy Frank Pollaro.)

Figure 1-2. A wet bar wall, made with quilted makoré panels and cabinets, pomele sapele bent-laminated doors, and a granite counter top, was designed by Dave Boykin and made by the three-man shop of Boykin-Pearce Associates, Denver, Colorado. (Photo courtesy Dave Boykin.)

Just like craftsmen today, early craftsmen had good reason to go to such trouble to fabricate veneers. In ancient Egypt, fine woods of interesting and contrasting figure had to be transported great distances, making them scarce. Cutting the wood into thin layers enabled it to cover more surface area. Also, rare and highly prized burls, large knotty growths found in many species of woods, will check, crack, and warp unless sawn very thin (Figure 1-3). Additionally, thin woods can be arranged and combined in intricate patterns, regardless of grain direction or species, without problems due to wood movement (see Chapter 2).

When circular saws came into use during the Industrial Revolution, veneers of 1⁄16" could be produced in large quantities. Veneer began to be used on a much greater scale. More people than ever before could own these inexpensive, mass-produced goods. Unfortunately, at this same time, veneer came to be associated with cheap, shoddy construction. The idea of a fine veneer covering over a cheap interior has been associated with the process ever since. Dictionaries today define veneer as “to disguise with superficial polish” or a “false show of charm” (Webster’s Dictionary, New Edition).

Figure 1-3. Ziggurat Chest of Drawers, 60" x 24" x 18", by furniture artist Silas Kopf of Northhampton, Massachusetts, features burl veneers with mother-of-pearl inlay banding. (Photo courtesy Silas Kopf.)

The middle class grew tremendously as labor shifted from working the land to working in factories. Technology continued to advance and veneer became ever thinner. With the incorporation of the mechanized knife in the early 20th century, veneer could be sliced to ⅓2" or less. (Today, most U.S. veneer is 1⁄28".) This was a huge advance in the efficient use of woods. The veneer was cut thinner, allowing it to cover more surface area, and the saw kerf (waste from the thickness of the saw blade itself) was eliminated. Far more veneer with a matching pattern could be produced, allowing for the coverage of larger areas, including entire rooms (Figure 1-2), with the same uniform pattern.

Then, due to the popularity of exotic woods during the first half of the 20th century, some of the finest furniture being produced was made using veneers (Figure 1-1). Consequently, during the last 200 years, veneer has lived a dual existence as the best and worst that wood furniture design has to offer. Contemporary furniture artists have again turned to veneer for both the beauty and luxury it offers as well as its economy and practicality (Figure 1-4).

Figure 1-4. A very practical set of three nesting tables by Jonathan Benson combines purpleheart veneer with stained curly maple turnings (20" x 26" x 20"). Although it might have been possible to make the curved side panels in solid wood instead of laminated veneers, the cost would have been prohibitive.

Advantages of veneer

With the rapid rate of deforestation and the near disappearance of an increasing number of tree species, use as veneers may be the only alternative left for many types of woods. Already, many species and rare figure configurations are only available in veneer form (see here). Some exceptionally rare species, such as premium-grade fiddleback makoré, may only appear on the market as one or two large veneer logs every few years.

The yield advantage of using veneer is tremendous. Take a given log and rough-cut 1"-thick boards from it. The lumber, dried and planed on both sides, yields a ¾"-thick board that will cover one square foot of surface area for every board foot of lumber saw...

Table of contents

- Cover

- Title

- Copyright

- Dedication

- Acknowledgments

- Contents

- Chapter 1: Veneering Then & Now

- Chapter 2: From Forest to Shop

- Chapter 3: Cutting, Matching & Taping Veneers

- Chapter 4: Substrates

- Chapter 5: Adhesives

- Chapter 6: Pressure & Presses

- Chapter 7: The Edge

- Chapter 8: Problems, Repairs & Finishing

- Chapter 9: Complex Matching, Inlays & Borders

- Chapter 10: Marquetry & Parquetry

- Chapter 11: Band-Sawing Veneers

- Chapter 12: Mirror Frame

- Appendix 1: Glossary

- Appendix 3: Veneering Suppliers