![]()

Chapter 1

Logistics Challenges

1.1. Introduction

The historical perspective previously presented tackles various problems that logisticians have to face. Many challenges still have to be taken on. However, to better understand the extent of these challenges, it is necessary to know the basics of logistics and its evolution in the last decades.

First of all, this chapter presents the forward logistics process and discusses the flows going from suppliers to end customers. It tackles the “actors”, the material, information and financial (money) flows, as well as the main activities of the forward supply chain. Henceforth, in this chapter, any reference to the term “supply chain” will imply the “forward supply chain”.

We then present how chains are evolving into complex structures and becoming networks. The customer–supplier relationship is no longer clearly defined and the game leader is changing. Indeed, supply sources are multiplying. Moreover, businesses have subsidiaries all around the world. Their customers, who have a wide variety of tastes that can be specific to each region, are also scattered around the world. This leads, amongst other things, to a multiplication of flows and transport networks that are also becoming more complex.

Manufacturing of all these products requires non-renewable natural resources that will not go back unaffected into the environment. Our society is only starting to realize the impact of massive consumption. This questions logistics design and management.

The conclusion of this chapter summarizes the most important problems and limits of actual supply chains. It also provides some ideas of solutions, which are then developed in the next chapters.

1.2. Forward supply chain

This section summarizes the main concepts of the logistic process, which will be used as a basis to understand the reverse logistics challenges presented in Chapters 2, 3 and 4. This does not intend to be an exhaustive compiling of what logistics is, but rather refers the reader toward more specialized books [BLA 07, SIM 08, STO 01].

1.2.1. Structure and actors

To summarize, logistics is defined as a set of activities involved in the flows between suppliers and customers. Supplier must be understood here in the broad sense of the word. Indeed, it can stand for raw material suppliers as well as for finished goods or service suppliers, such as a mechanical maintenance service for the vehicles of a public urban carrier. Customers can be business units as well as end customers. We can then, respectively, speak of business-to-business (B2B) commerce and business-to-customer (B2C) commerce. More specifically, the actors are suppliers of raw materials, components or modules, subcontractors, manufacturers, assemblers, distribution and sale centers, wholesalers, carriers, retailers, and end customers.

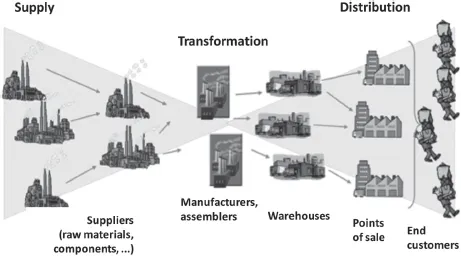

Supply chain activities can be described in three main functions. These functions are illustrated in Figure 1.1 [LEE 93]:

– supply of raw material;

– transformation of raw materials into intermediate products and finished goods;

– distribution of finished goods to end customers.

Supply includes activities whose purpose is to receive the right materials and components at the right time, in the right quantities, and at the right place. Complying with business quality standards, it includes the choice and the type of relationships with suppliers, decisions on quantities and on formats to be ordered, and when orders should be placed. Moreover, decisions on the activities carried out by the businesses or those that are subcontracted are intimately linked to the supply function. These activities also concern the choice of transportation mode (air, marine, rail, road, and multimodal), the type of carrier (private, public, and own account), and the means of transport (pickup truck, semi-trailer, etc.) that we will use to transport orders to the businesses.

Materials and components are then received by manufacturers or assemblers. They are processed or assembled according to the required transformation operation. The quantity to be produced for each time period, the production and transfer batch size, and the resources to be used are all parts of the decisions that should be taken for the transformation operation.

Finished goods are distributed to retailers or directly to end customers. There are several distribution channels to dispatch products and services between manufacturers and end customers. Indeed, more and more businesses offer their products via websites, where consumers can choose the desired products. This leads to different combinations of conventional transportation modes, types, and means. The most frequently used distribution channel consisted of transporting products from manufacturers to distributors, who were transporting these products to retailers; all of that in large batch sizes to favor an economy of scale. However, online purchases by consumers involves transporting small packages directly to private individuals instead of full pallet loads transported to retailers.

Products, components, and materials are sometimes in transit in cross-docking centers. The cross-docking activity occurs during the supply, as well as during the distribution of goods. This consists of transferring the goods directly from one means of transportation to another, without any warehousing in-between. It can also be done, among other things, during a change in the transportation mode (e.g. from rail to road) or during the freight consolidation. A very tight synchronization is thus needed between acceptances and dispatching.

To ensure the product quality, businesses offer a customer service. This service can comprise the maintenance of sold goods, such as cars or computers. It can also involve answering customer questions about the maintenance that should be done and, if necessary, of guiding them through the actions that need to be carried out. Customer questions are quite diverse: for example, where can they get spare parts or accessories, what to do if they want to return or exchange their products, how to use products in a specific context … These services take various forms: customer service at the outlet, at the point of use, phone customer service, and nowadays, online customer service.

1.2.2. Flows

The type of flow that usually first comes to mind is the finished good flow. However, flows between customers and suppliers are more diverse and comprise material, information, or financial flows, or often a combination of all of the above.

Material flows other than finished good flows are often neglected during the design and management of a supply chain or of one of its components. However, they have a major impact on the fluidity in the operations. For example, the design of a factory is mostly based on the production process [HER 08, SUL 09, TOM 03]. This process results from the connection necessary to the routing of products between work centers. These work centers’ inventories must be regularly replenished. However, the required flows are rarely taken into account during design. The same is true for spare parts, components, pallets, and unit loads. They can be handled in one specific place or transported between two different facilities.

Activities requiring information flows can be found on all levels of the supply chain. Information circulates as much between suppliers and manufacturers as between manufacturers and customers. Traditionally, information between business units was transmitted via paperwork and thus involved physical flows, via the post office or other mail services. Similarly, the transfer between work centers was also done through paperwork. However, the percentage of information circulating electronically has significantly increased over the past few years. This has significantly reduced times compared to the transmission of printed documents. This has also changed business processes between partners and has involved data exchange software.

As for financial flows, they have also changed by following the trend and by taking advantage of new technologies. Indeed, checks and bank drafts were, in the past, the only ways to transfer money between two businesses. Concerning private individuals, sending checks by mail and cash payments at the counter of a bank were the most common payment methods. In all these cases, movements were required, which then resulted in delays. Information technologies have revolutionized payment methods by enabling money transfer in a single click. They have unbelievably shortened delays in financial flows, since they are nowadays electronically transferred. Transactions are carried out on bank accounts by businesses and private individuals via secure websites. Credit notes, various taxes, tax relief, subsidies, and payments can all be transferred in a few seconds.

1.2.3. Design and management objectives

It is important to note that up until very recently, decisions were taken strictly from an economic point of view. Business objectives are mostly oriented toward profitability and competitiveness. After minimizing costs, businesses then understood that it was preferable to maximize profits, while aiming to improve the performances of each chain activity. This is still an economic performance. However, the competition between businesses gives more and more influence to customers, because it indirectly forces businesses to satisfy customer needs better than their competitors. The concept of referred service level corresponds to the customer satisfaction level. For example, for a retailer, this corresponds to the percentage of times when customers find the desired product in the shops. The service level is also measured in terms of delays. Section 1.3.2 is about the evolution of consumer needs.

It is recognized that globalization increases the product supply. This increase leads to a change in consumer behaviors. Not only do they seek cheaper products, but also good quality products that will be delivered in a shorter time and that are moreover customized! This increases the competition between businesses, which then must seek at any costs to reduce their expenses and must be ingenious in order to survive.

1.3. Higher, further, bigger …

This section presents various actors and their internationalization options. It discusses changes on the level of the relationships between businesses, customers, suppliers, and their business partners, as well as the consequences on transportation needs.

1.3.1. Suppliers throughout the world

The reduction of supply costs of all input forms is one of the most frequently used strategies by businesses. This strategy is used no matter what type of business it is (production, assembly, distribution, or retailing), even if the customer service is concerned. Supply can take several forms: purchasing, subcontracting, and outsourcing. Up until recently, they were carried out mainly locally or at least within a single country. However, the development of transport networks and the suppression of tariff gatekeeping facilitate the trade between countries and the access to new suppliers.

Therefore, manufacturers import raw materials from all over the world because of their availabilities and lesser costs. Let us take the example of paper manufacturers. Canada is one of the main wood fiber producers for paper. Tropical countries, such as Brazil, produce eucalyptus with a growing rate much higher than trees from Scandinavian forests [COS 06]. Therefore, Canadian businesses are nowadays less competitive in this industry. Manufacturers are also dealing with foreign subcontractors and suppliers for their parts. For example, for computer, phone, and game console manufacturers, electronic boards are manufactured in emerging countries, such as Mexico and China.

The same phenomenon can be observed for independent retailers. They had already started gathering together to increase their purchasing power. For example, in Canada, Rona is a retailer selling ...