eBook - ePub

Fundamentals of Manufacturing For Engineers

T F Waters

This is a test

- 334 páginas

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

eBook - ePub

Fundamentals of Manufacturing For Engineers

T F Waters

Detalles del libro

Vista previa del libro

Índice

Citas

Información del libro

This textbook will be welcomed throughout engineering education as the one-stop teaching text for students of manufacturing. It takes the student through the fundamental principles and practices of modern manufacturing processes in a lively and informative fashion. Topics include casting, joining, cutting, metal deformation processes, surface treat

Preguntas frecuentes

¿Cómo cancelo mi suscripción?

¿Cómo descargo los libros?

Por el momento, todos nuestros libros ePub adaptables a dispositivos móviles se pueden descargar a través de la aplicación. La mayor parte de nuestros PDF también se puede descargar y ya estamos trabajando para que el resto también sea descargable. Obtén más información aquí.

¿En qué se diferencian los planes de precios?

Ambos planes te permiten acceder por completo a la biblioteca y a todas las funciones de Perlego. Las únicas diferencias son el precio y el período de suscripción: con el plan anual ahorrarás en torno a un 30 % en comparación con 12 meses de un plan mensual.

¿Qué es Perlego?

Somos un servicio de suscripción de libros de texto en línea que te permite acceder a toda una biblioteca en línea por menos de lo que cuesta un libro al mes. Con más de un millón de libros sobre más de 1000 categorías, ¡tenemos todo lo que necesitas! Obtén más información aquí.

¿Perlego ofrece la función de texto a voz?

Busca el símbolo de lectura en voz alta en tu próximo libro para ver si puedes escucharlo. La herramienta de lectura en voz alta lee el texto en voz alta por ti, resaltando el texto a medida que se lee. Puedes pausarla, acelerarla y ralentizarla. Obtén más información aquí.

¿Es Fundamentals of Manufacturing For Engineers un PDF/ePUB en línea?

Sí, puedes acceder a Fundamentals of Manufacturing For Engineers de T F Waters en formato PDF o ePUB, así como a otros libros populares de Tecnología e ingeniería y Ingeniería industrial. Tenemos más de un millón de libros disponibles en nuestro catálogo para que explores.

Información

Chapter One

Engineering manufacture in modern society

All too frequently students skip reading the introductory chapter of textbooks such as this because they do not see them as containing the essence of the basic manufacturing processes that they are required to learn, and hence they believe that they are unlikely to contain potential examination material! The fact that you are reading this now is encouraging, so please continue to read the remainder of this chapter before embarking upon the more detailed studies contained in subsequent chapters.

In addition to providing the reader with a broad overview of current engineering manufacture, and how it is changing to meet the challenges of the twenty-first century, this first chapter also briefly describes how manufacturing fits into the overall economy of a country, and how it contributes to the material standard of living of its population. The important issues of safety and the need to preserve our environment are also considered.

1.1 Engineering in a modern industrial economy and as a career

If a country is blessed with huge natural resources of oil and minerals, ignoring political issues, it should be possible to provide a high standard of living for its people. This can be achieved either by buying in all the products and services required or by establishing a solid industrial base of its own. Certain Middle Eastern oil-producing countries are good examples of the former approach, and the United States is a prime example of the latter.

Unfortunately, natural reserves do not last forever, so countries that fail to establish an industrially based economy, although still able to pay for all the goods and services that they want for a limited period, will eventually be faced with a rapidly declining standard of living as their natural wealth reserves become exhausted. However, in countries that can offer a wide range of goods and services that others wish to buy reliance upon natural wealth is reduced, because such an industrially based economy is inherently wealth creating. This is because any commercially successful enterprise must make a profit, i.e. its income must exceed its costs, and is therefore a wealth creator rather than a wealth user.

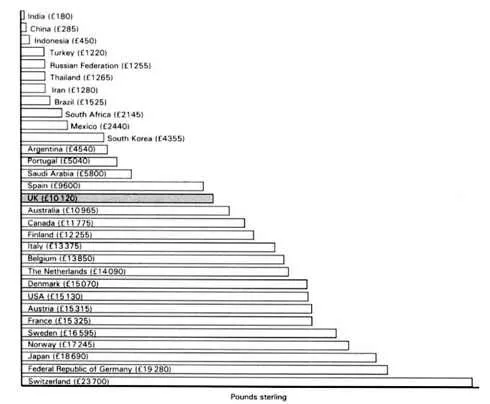

Engineers are an essential element in such a wealth-generating economy, and the more innovative their designs, and the more efficiently they make their products, the greater will be the level of wealth generation. Good examples of countries that have achieved such success in recent years are Germany and Japan. Indeed, manufacturing has been so successful in improving productivity per employee in the past two decades that it is now possible to meet the increasing demand for goods using fewer and fewer workers. This presents those working in manufacturing with ever greater technical challenges, particularly as an increasing number of Third World countries enter the world’s industrial market place. Figure 1.1 illustrates clearly how heavily industrialized countries are far more productive per head of population (per capita) than less industrially efficient, labour-intensive ones. But for how long will countries such as India and China be content to generate just 1 per cent of the gross domestic product (GDP) per capita that Japan currently achieves?

So if you wish to pursue a challenging career that offers the opportunity to make a positive contribution to the future prosperity of your country, as well as providing a high degree of personal satisfaction, then engineering is probably a good choice.

Note The key to efficient production is the concept of added value (§10.5). The more effectively that the value of an item is increased at each stage of manufacture, the more productive and profitable the overall production system is likely to be. Even service industries such as hospitals and schools are turning to this method of assessing their operational efficiency, although the parameters used in measuring added value are less obvious than in a manufacturing environment, and are often the subject of heated debate.

1.2 Technical and organizational considerations

Engineering manufacturers are extremely diverse, ranging from drawing pin manufacturers to producers of the latest commercial jet aircraft. While the difference in technology and manufacturing complexity between two such extreme examples is enormous, the commercial basis of operation is similar because, whatever the end product, it has to be made in some way, and there must be a customer base. Therefore a sales/marketing organization is needed to locate potential customers, and an efficient manufacturing system is required to turn raw materials into the finished product. This is of course, an overly simplistic description of any manufacturing company’s structure as it ignores many essential supporting activities such as finance, personnel, secretarial support, transport, building services maintenance, etc. However, most engineering manufacturers have a broadly similar structure, and this usually involves a product flow system typical of that shown in Figure 1.2. Because Figure 1.2 illustrates a typical routing for an order to produce items in a company’s existing range, design and production planning activities have been omitted.

Figure 1.1 GDP per capita in 1992 for countries with a GDP in excess of £50000 million (World Bank 1994).

1.2.1 The essential relationship between design and manufacture

Every company must continually develop new and improved products, as it is a fact of life that no company can commercially stand still. It either grows or dies.

Figure 1.2 Typical flow chart for making engineering items from an existing product range.

Because the sales and marketing department is best placed to know the needs of the market place and what competitor companies are offering, it must play a major role in helping to draw up future product specifications. Nevertheless, the technical responsibility for producing the detailed specifications required to make these new products lies with the design function.

Unfortunately, in the past, designers have tended to consider little, if at all, the implications of their designs on manufacturing costs. This was mainly because of a lack of manufacturing process knowledge on the part of the designer, but happily this problem is now being overcome as an increasing number of engineering courses include “Design for Manufacture” as a core theme.

Because manufacturing costs are usually at the heart of product selling price calculations, it is vital that designers and production planning engineers work as equal partners in a team to produce the most cost-effective designs. With this approach design engineers soon realize, for example, that calling for, say, six different radii on a particular part where two would have been acceptable greatly increases the number of cutting tools required, or that demanding unnecessarily close component dimensional tolerances will probably result in the need for much more expensive manufacturing processes.

Note A production planning engineer is someone who plans in detail how a part can be most efficiently made, taking into account the number required, the materials involved, and the equipment available. It is also usually this person’s responsibility to specify and/or design any special fixtures and tooling that may be needed, as well as to write any computer-controlled machine tool programs that may be required.

1.2.2 Some modern approaches to efficient manufacture

In addition to closer links being forged between the design and manufacturing functions, other advances have been made in the quest to increase production efficiency and to minimize the total time required for a new product idea to reach the market place—an essential requirement as product life cycles become progressively shorter.

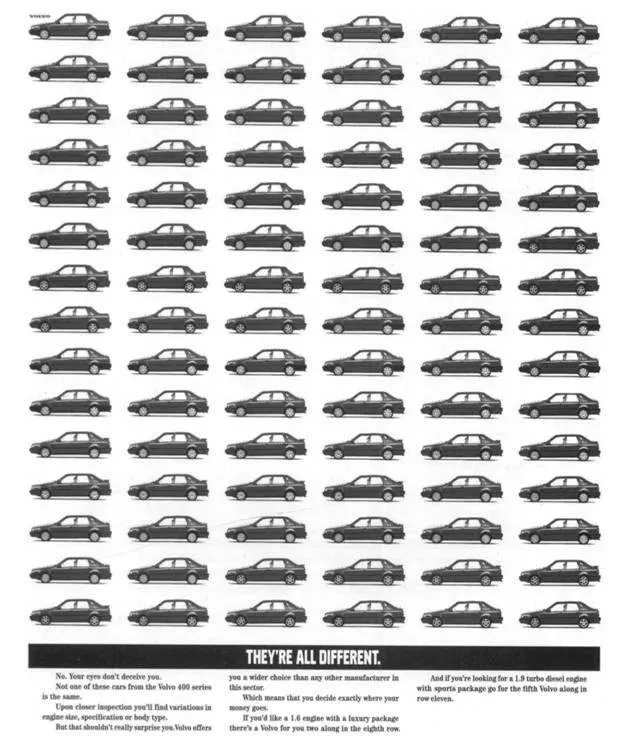

Another major change that has taken place in recent years is that the customer now demands much greater product choice than ever before. This is particularly so in the automotive industry. Gone are the days when Henry Ford declared that customers could have any colour they liked as long as it was black. The current situation is very different and is well illustrated by an advertisement from the car manufacturer Volvo (Fig. 1.3)—and this applies to just one of their models! Such increasingly demanding marketing requirements have resulted in more integrated and flexible systems of design and manufacture being adopted, three such techniques being concurrent engineering, just-in-time and computer-integrated manufacture.

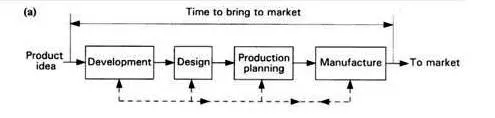

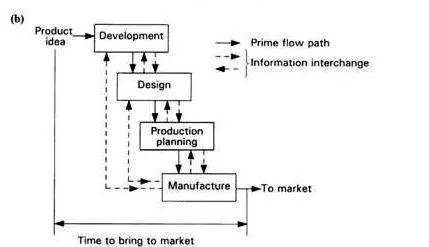

1.2.2.1 Concurrent engineering

If one examines the traditional way in which a new product is progressed from the conceptual design stage to quantity production, it will be seen to follow a logical number of sequential steps (Fig. 1.4a). What is not so apparent until one has lived through such exercises is that an enormous number of modifications, redesigns, revisions and up-dates are usually generated, mainly as a result of problems encountered at the manufacturing stage. A figure quoted in 1992 (Gould 1992) suggested that in the UK 50 per cent of all design office time is spent on design modifications, but in Japan this figure is nearer 10 per cent. It is claimed that the main reason for Japan’s greater efficiency is that manufacturing requirements and their implications for design are resolved long before production starts, i.e. concurrently with the initial design and development stages (Fig. 1.4b).

Figure 1.3 Advertisement for ninety variants of just one car model. (Courtesy of Volvo Cars Ltd, Marlow, Bucks.)

Figure 1.4 (a) Traditional method of introducing a new product. (b) Concurrent engineering approach to introducing a new product.

The subject of concurrent engineering is complex (Lambert 1994), and makes extensive use of modern computer technology, but it is sufficient here for the reader to understand the basic philosophy, which is to work simultaneously on as many stages of development, design and production planning as possible. This then solves many problems before they occur, as the product design and the optimum method of manufacture are developed concurrently.

1.2.2.2 Just-in-time manufacture

When a batch of components is ordered, traditional methods of manufacture have led to the attitude that, because a few problems are bound to occur somewhere, an element of rework or scrap replacement is unavoidable. This means that one accepts either that late delivery of part of the batch is inevitable or that a slightly larger batch than is required must be ordered to overcome the problem, i.e. the just-in-case strategy. Such a negative approach is, of course, a very efficient way of losing money, and begs the question of why a few items will always be made incorrectly. How this problem may be overcome is briefly discussed in Chapter 10 (§10.4), but here we are concerned with just-in-time (JIT) manufacture, rather than the wasteful just-in-case approach.

A basic principle of JIT (Bicheno 1991) is that goods are made not only in exactly the number required, but also at the last possible moment, while still meeting the required delivery schedule. An implication of this strategy is that each part must be made right every time, and this applies equally to all bought-in items, which must also be delivered on time without fail. This requires great faith in one’s suppliers who, in turn, must therefore also operate on the JIT principle.

Because of the large and continuous volumes of production common in the automotive industry, car manufacturers usually have most to gain from operating JIT. Indeed, JIT was developed by Toyota in Japan. Apart from ensuring that the highest levels of manufacturing consistency are maintained, JIT also minimizes stock levels of bought-in items that have to be stored.

A classic example of the use of JIT occurs at the Nissan car plant in Sunderland (Wickham 1993), where seats are ordered for the Micra model just 45 minutes before they are required on the assembly line. This is achieved by the seat supplier being located 3km away, and being in continuous computer contact. Five other local suppliers also supply parts on a similar JIT basis to this production plant.

A useful commercial benefit of JIT is that one sometimes receives payment for the finished product before component suppliers have to be paid, thus establishing a very favourable cash flow situation.

1.2.2.3 Computer-integrated manufacture

With the increasing use of computer numerically controlled (CNC) machine tools, and the development of sophisticated computer software packages designed to carry out administrative functions such as production scheduling and control, automatic materials ordering, etc., numerous attempts hav...

Índice

- Cover Page

- Title Page

- Copyright Page

- Preface

- Chapter One: Engineering manufacture in modern society

- Chapter Two: Shapes made from molten metals—casting

- Chapter Three: Plastic deformation of metals

- Chapter Four: Processing of plastics and elastomers

- Chapter Five: Joining processes

- Chapter Six: Surface treatment of materials

- Chapter Seven: Powder metallurgy

- Chapter Eight: Shapes cut from the solid—material removal processes

- Chapter Nine: Computer numerical control of machine tools

- Chapter Ten: Productivity and automation

- Chapter Eleven: Quality assurance

Estilos de citas para Fundamentals of Manufacturing For Engineers

APA 6 Citation

Waters, T. (2017). Fundamentals of Manufacturing For Engineers (1st ed.). CRC Press. Retrieved from https://www.perlego.com/book/1500757/fundamentals-of-manufacturing-for-engineers-pdf (Original work published 2017)

Chicago Citation

Waters, T. (2017) 2017. Fundamentals of Manufacturing For Engineers. 1st ed. CRC Press. https://www.perlego.com/book/1500757/fundamentals-of-manufacturing-for-engineers-pdf.

Harvard Citation

Waters, T. (2017) Fundamentals of Manufacturing For Engineers. 1st edn. CRC Press. Available at: https://www.perlego.com/book/1500757/fundamentals-of-manufacturing-for-engineers-pdf (Accessed: 14 October 2022).

MLA 7 Citation

Waters, T. Fundamentals of Manufacturing For Engineers. 1st ed. CRC Press, 2017. Web. 14 Oct. 2022.