eBook - ePub

The Modern Theory of the Toyota Production System

A Systems Inquiry of the World's Most Emulated and Profitable Management System

Phillip Marksberry

This is a test

- 451 páginas

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

eBook - ePub

The Modern Theory of the Toyota Production System

A Systems Inquiry of the World's Most Emulated and Profitable Management System

Phillip Marksberry

Detalles del libro

Vista previa del libro

Índice

Citas

Información del libro

Numerous books have been written about Toyota's approach to workplace improvement; however, most describe Toyota's practices as case studies or stories. Designed to aid in the implementation of Lean manufacturing, The Modern Theory of the Toyota Production System: A Systems Inquiry of the Worlds Most Emulated and Profitable Management System expla

Preguntas frecuentes

¿Cómo cancelo mi suscripción?

¿Cómo descargo los libros?

Por el momento, todos nuestros libros ePub adaptables a dispositivos móviles se pueden descargar a través de la aplicación. La mayor parte de nuestros PDF también se puede descargar y ya estamos trabajando para que el resto también sea descargable. Obtén más información aquí.

¿En qué se diferencian los planes de precios?

Ambos planes te permiten acceder por completo a la biblioteca y a todas las funciones de Perlego. Las únicas diferencias son el precio y el período de suscripción: con el plan anual ahorrarás en torno a un 30 % en comparación con 12 meses de un plan mensual.

¿Qué es Perlego?

Somos un servicio de suscripción de libros de texto en línea que te permite acceder a toda una biblioteca en línea por menos de lo que cuesta un libro al mes. Con más de un millón de libros sobre más de 1000 categorías, ¡tenemos todo lo que necesitas! Obtén más información aquí.

¿Perlego ofrece la función de texto a voz?

Busca el símbolo de lectura en voz alta en tu próximo libro para ver si puedes escucharlo. La herramienta de lectura en voz alta lee el texto en voz alta por ti, resaltando el texto a medida que se lee. Puedes pausarla, acelerarla y ralentizarla. Obtén más información aquí.

¿Es The Modern Theory of the Toyota Production System un PDF/ePUB en línea?

Sí, puedes acceder a The Modern Theory of the Toyota Production System de Phillip Marksberry en formato PDF o ePUB, así como a otros libros populares de Negocios y empresa y Operaciones. Tenemos más de un millón de libros disponibles en nuestro catálogo para que explores.

Información

1

Systems Theory and the Relation to TPS

1.1 Why Systems Theory for the Toyota Production System?

For many years improvement activities, initiatives, and programs have been implemented throughout organizations in an effort to achieve companywide goals. Traditionally, managers focus on one part of the organization and, once a task is completed, shift their attention to another area.

Initially, this strategy works in isolated areas of the company, but on a larger scale, the organization suffers. The reason is that organizations are systems. Changing one aspect of the organization without knowing how it can impact the whole is not only risky but also dangerous.

Unfortunately, the Toyota Production System (TPS) is treated the same way. When standardized work is implemented in manufacturing without ergonomic standards, TPS can lead to worker intensification. Even the simplest adjustments in an organization can drastically harm other areas if not properly understood. TPS is a system that has organized components and interacting elements that form an integrated whole. Without understanding how the pieces fit together, TPS is more likely to weaken a system rather than strengthen it.

Another analogy that can be used to describe interdependency in organizations is gardening. Plants cannot be successfully transplanted unless the soil and environment are the same. Unsuccessful transplanting occurs when a gardener makes decisions based on a plant’s outward appearance rather than decisions on what keeps a plant alive. A successful gardener has to know how the entire system works if a plant is to be replanted and live (Figure 1.1).

Figure 1.1

Systems thinking and gardening.

Systems thinking and gardening.

Unfortunately, many companies make the same mistake when implementing Lean. Organizations are mesmerized with Japanese words and new tools, almost everything that can be seen on the surface. When organizations implement the peripheral aspects of Lean, they are left wondering why they did not get the same benefits as Toyota. Systems thinking prevents users from making decisions on the peripheral aspects of Lean and focusing on the true aspects that keep the system alive and healthy. Without systems thinking, it is hard to distinguish what is peripheral and what is essential (Figure 1.2).

Figure 1.2

Systems thinking and TPS.

Systems thinking and TPS.

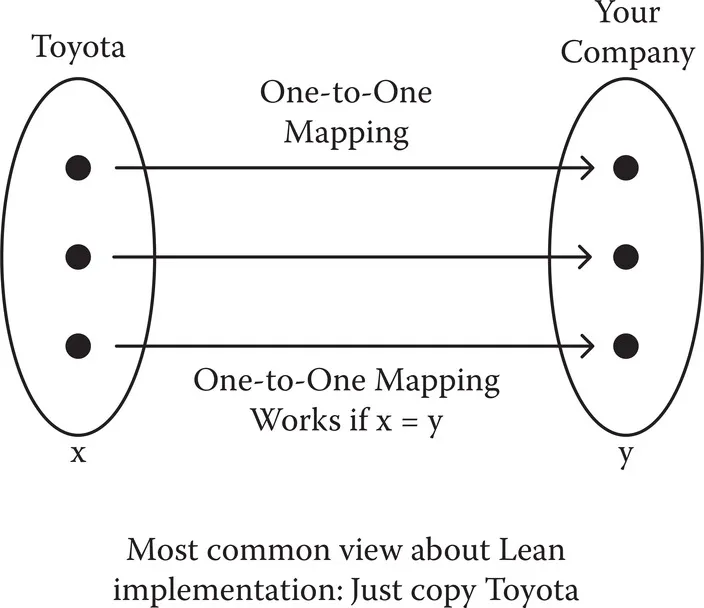

The same situation can be explained using abstract algebra. When two objects show a relationship and are structurally identical, they are called isomorphic. The isomorphic property is used in mathematics to explain how some relationships might work in uncharted territories when they have been proven to work in others. This one-to-one mapping function suggests that what works at Toyota can work anywhere (Figure 1.3). Or, if one aspect of TPS can work, then all other components and aspects can work as well. Of course, this one-to-one mapping concept for Lean implementation only works if both organizations are completely identical. This is why copying Toyota does not work.

Figure 1.3

One-to-one mapping function for Lean implementation.

One-to-one mapping function for Lean implementation.

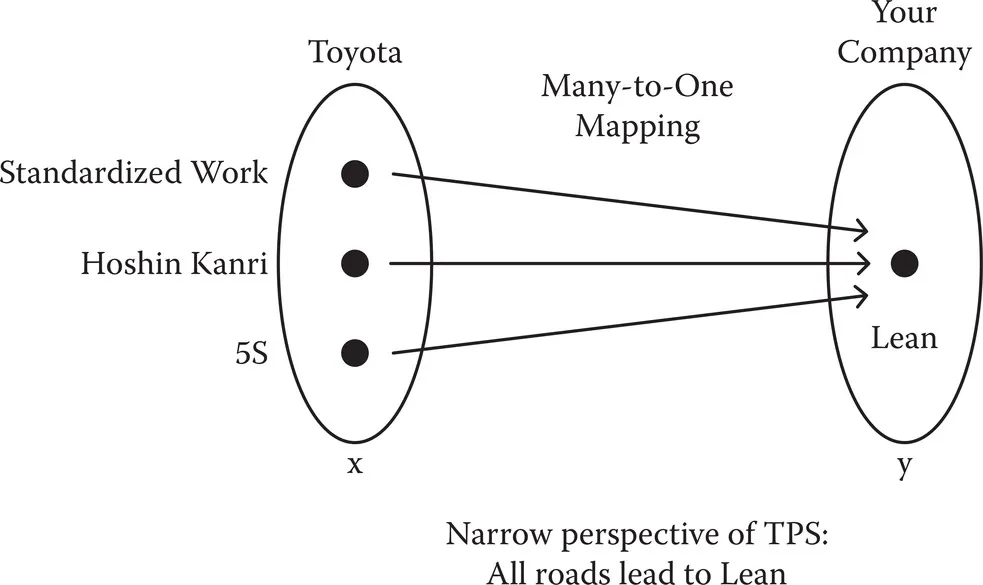

A less-complicated view of TPS is the implementation of a Lean technique or tool. Often, organizations choose not to treat TPS as an organizational strategy or business practice. In this case, industrial engineering tools such as 5S (i.e., five Japanese works starting with the letter “S” that describe workplace organization: seiri, seiton, seiso, seiketsu, and shit-suke), hoshin kanri, and standardized work are used to implement Lean. The view is that if the organization adopts the same tools as Toyota, then it is Lean. In algebraic terms, this is known as many-to-one mapping (Figure 1.4); the use of any tool is considered Lean in an organization trying to emulate Toyota. Unfortunately, adopting one or many of Toyota’s tools does not provide an organization a competitive advantage.

Figure 1.4

Many-to-one mapping function for Lean implementation.

Many-to-one mapping function for Lean implementation.

A more appropriate way to understand how TPS works is by examining the features that make it universal. By treating TPS as a system, practitioners can share a broader perspective for how TPS functions and operates. Systems thinking can help bring new insights and thinking for understanding TPS and provide a universal framework for organizational change. Systems thinking can also help in avoiding unintended consequences that can weaken the organization when one part of a system negatively impacts another. Most important, systems thinking can provide a big picture in solving complex problems by seeing the patterns instead of events for interpreting success.

The most universal features of TPS are its principles. In the 1950s, Taiichi Ohno, the creator of TPS, illustrated the company’s principles using a house, known today as the Toyota House. The house is constructed using the company’s four most basic principles: standardization, just in time, jidoka, and kaizen. The image of the house was used to teach suppliers about TPS and simply to illustrate that no part of the house can be built without the other, and a house can only be built from the ground up. Taiichi’s house is illustrated in Figure 1.5.

Figure 1.5

Ohno’s representation of TPS: Toyota House (House Thinking = Systems Thinking).

Ohno’s representation of TPS: Toyota House (House Thinking = Systems Thinking).

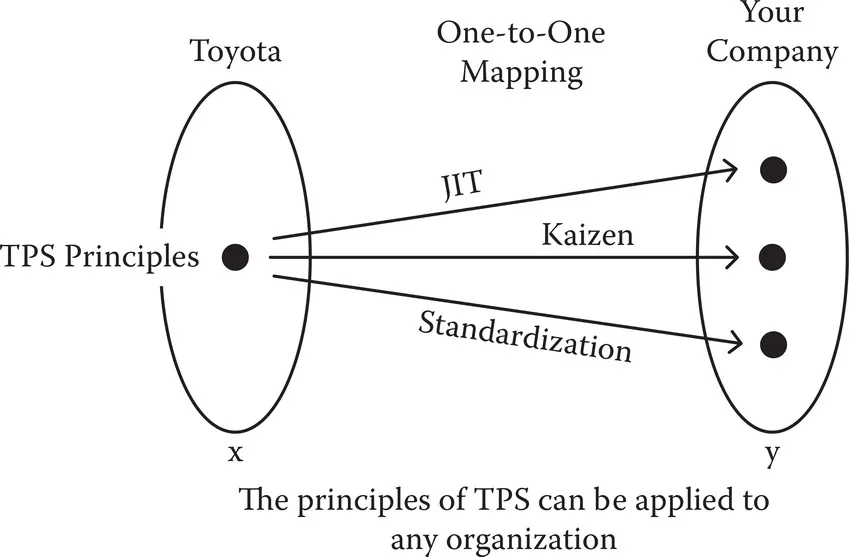

The universal nature of TPS can be illustrated by mapping Toyota’s principles using the one-to-many mapping function (Figure 1.6). In this context, the principles of TPS are universal to any organization, business function, or industry. Principle basis thinking represents the rules the organization chooses when making decisions. If every person shares the same rules, decisions will be made consistently in alignment with the company’s goals and objectives. Importantly, Ohno was more concerned about teaching the system of TPS (the house) rather than the features (such as the tools) that are specific in many ways to Toyota.

Figure 1.6

One-to-many mapping function for Lean implementation. JIT, just in time.

One-to-many mapping function for Lean implementation. JIT, just in time.

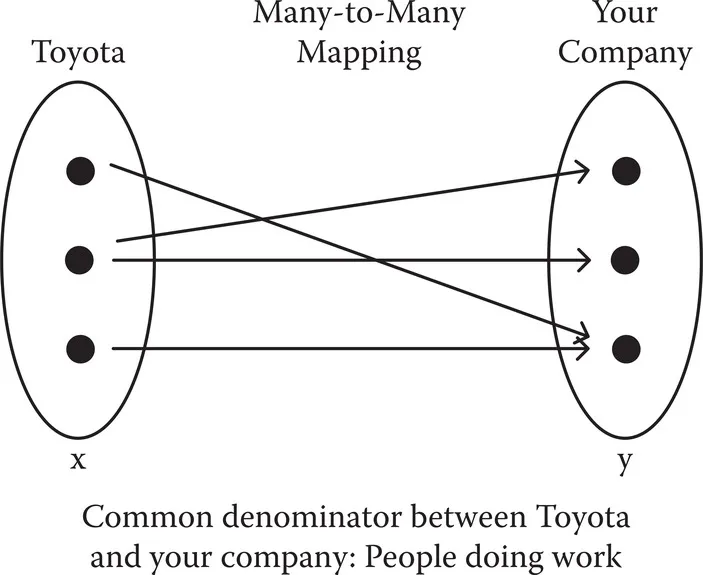

Finally, systems thinking offers a way to identify the same characteristics shared by Toyota and other companies. It is argued that TPS does not contain any elements or aspects that are not already present in organizations today; rather, it is the balance of how those elements interact that makes TPS unique. This can be illustrated using the many-to-many mapping function (Figure 1.7). The one aspect that is completely the same in all organizations today and at Toyota is people. Organizations have people doing work. Toyota has people doing work. The common denominator is people doing work. Surprisingly, many organizations emulate Toyota’s technical systems rather than their people systems. Systems thinking can help practitioners find the common denominators of TPS that are more easily applicable to their organization.

Figure 1.7

Many-to-many mapping function for Lean implementation.

Many-to-many mapping function for Lean implementation.

1.2 Why Systems Thinking is Not Popular When Implementing TPS

Systems thinking typically provides a long-term perspective when studying complex problems. Most organizations want quick gains that do not require extensive effort over the long term. It is not uncommon for organizations to want to implement Lean overnight and recei...

Índice

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Foreword

- Preface

- Acknowledgments

- Introduction

- About the Author

- Chapter 1 Systems Theory and the Relation to TPS

- Chapter 2 The Property of Holism in TPS

- Chapter 3 The Property of Goal Seeking in TPS, Part 1

- Chapter 4 The Property of Goal Seeking in TPS, Part 2

- Chapter 5 The System Property of Regulation in TPS

- Chapter 6 The System Property of Differentiation in TPS

- Chapter 7 The System Property of Hierarchies in TPS

- Chapter 8 The System Property of Transformation in TPS

- Chapter 9 The System Property of Entropy in TPS

- Chapter 10 The System Property of Reversibility in TPS

- Chapter 11 The System Property of Negative Entropy in TPS

- Chapter 12 The System Property of Requisite Variety in TPS

- Chapter 13 The System Properties of Interrelationship and Interdependence in TPS

- Chapter 14 The System Property of Equifinality in TPS

- Chapter 15 Summary

- Index

Estilos de citas para The Modern Theory of the Toyota Production System

APA 6 Citation

Marksberry, P. (2012). The Modern Theory of the Toyota Production System (1st ed.). Taylor and Francis. Retrieved from https://www.perlego.com/book/1517079/the-modern-theory-of-the-toyota-production-system-a-systems-inquiry-of-the-worlds-most-emulated-and-profitable-management-system-pdf (Original work published 2012)

Chicago Citation

Marksberry, Phillip. (2012) 2012. The Modern Theory of the Toyota Production System. 1st ed. Taylor and Francis. https://www.perlego.com/book/1517079/the-modern-theory-of-the-toyota-production-system-a-systems-inquiry-of-the-worlds-most-emulated-and-profitable-management-system-pdf.

Harvard Citation

Marksberry, P. (2012) The Modern Theory of the Toyota Production System. 1st edn. Taylor and Francis. Available at: https://www.perlego.com/book/1517079/the-modern-theory-of-the-toyota-production-system-a-systems-inquiry-of-the-worlds-most-emulated-and-profitable-management-system-pdf (Accessed: 14 October 2022).

MLA 7 Citation

Marksberry, Phillip. The Modern Theory of the Toyota Production System. 1st ed. Taylor and Francis, 2012. Web. 14 Oct. 2022.