![]()

1

How Manufacturing Will Work

Chaos, Pain, and Transformation

When Francis Cabot Lowell, through a supreme act of industrial espionage, memorized the guts of the English power loom systems he had seen in 1811 on an extended stay in Great Britain, he launched a two-hundred-year run for American manufacturing. Lowell pulled together all the disparate functions of the textile production process—carding, dyeing, spinning, weaving, bleaching, tasks that had been contracted out to rural farmwives and small shops—and arranged them in sequence in a single site, a new four-story mill on the banks of the Charles River in Waltham, Massachusetts, the prototype for thousands of factories that followed. The first experiment was successful beyond the incorporators’ dreams, a money machine; 200 percent profits fueled more and bigger mills—Lowell, Lawrence, Lynn, and Manchester, New Hampshire’s Amoskeag complex, the biggest cotton plant in the world—more innovation, and urban communities of mill workers. The golden era for manufacturing had begun.

A DEDICATION TO BRICKS AND MORTAR

But process innovation and dedication to scale did not come without some pain. Complete vertical integration of the textile process led to captive company workers, Taylorism, piece rates, and huge profits. The brief utopian era of the mill girls—educated Yankee farm girls who left the countryside for an average of two years’ work in the mill city of Lowell, where they attended concerts and lectures and shopped for machine-made items—gave way within less than ten years to cheaper immigrant labor. And within fifty years, the promise of complete vertical integration of the textile process had led to strikes and work stoppages, lung diseases, disinvestment in machinery, and a litany of excess and inflexible profit production whose aftereffects have lingered long beyond their usefulness.

TECHNOLOGY OVERTAKES MANUFACTURING

Manufacturing progress has always been limited by technology and human factors—availability, training, wages—but we must learn to apply the two main components of every production system, machines and people, in different ways. In the coming decades, manufacturing professionals will be technology partners, rather than servants to machines. The future isn’t about bigness, or powerfulness, or economies of scale. It’s about smartness, values, supreme technical mastery, and constant innovation: the Technology Machine.

Most of us survived the hard marches through the computer crusades of the seventies, the eighties’ lighthearted flirtations with excellence overlaid on rigid hierarchies, and the nineties’ over-the-hill-but-can’t-quite-see-the-bottom struggle toward an enlightened industrial enterprise.

“Leading edge” in the nineties was about people, systems, and communications. Companies like USX that grew successful by building bigger operations had to learn to think small and light (Nucor’s electric-fired mini-mills, for example); they needed to reach outside their walls to find suitable teammates (Japanese steel producers, for example). Still, it wasn’t enough.

Manufacturing excellence alone will not carry good companies into the next millennium. Simple manufacturing excellence has become, as has quality, merely the ticket to the big leagues. What does this mean for manufacturing pioneers and survivors right now?

TRANSFORMATION IN THE NINETIES

The nineties will be known as the decade that witnessed final dissolution of all entities we grew up with—our churches, schools, families, government, businesses, health-care systems, music, maybe even our tax and currency systems. The bad news is that this unraveling will continue, but the good news is—for only another four or five years. Manufacturing professionals should expect to feel great discomfort, many surprises, big highs and lows, and confusion, and to be generally “off balance.” Coping skills and pharmaceutical solutions—Prozac, stress-reduction clinics, and natural mood levelers—will be perfected and stretched to their limits.

RECOVERY FROM CHAOS AND PAIN

We want to put the pieces back in order again. We refuse to continue in this uncomfortable, “disorganized” state, so it seems only reasonable, and painfully natural, that we will reassemble the pieces. The glorious product—for a few companies—will be a true re-formation, a rebuilding into new entities.

And, as usual, business—not government or education—will lead the way, because it is those of us in business who are responsible for designing, making, and shipping things, who need effective structure to live.

It is a dangerous time. With the stock market soaring and lurching uncertainly, many companies feel that they have already been reengineered, empowered, and reborn. Why change, why anticipate the difficulty of any more distractions from returning to the happy business of being successful? Why now?

Lotus, Bowmar, Apple, DEC, Data General, Apollo, NeXT, USX (formerly USSteel), NCR (National Cash Register), General Motors—the long line of at one time equally happy, busy, and successful companies stretches across a landscape we all occupy. We’re stepping around the detritus. Each of these companies made one or two strategic errors—perhaps depending on proprietary software or sloppy manufacturing, or not listening to customers. And each failed to recognize and anticipate, and to be ready for big technology swings.

Motorola’s Six Sigma initiative, for example, and the Baldrige Award have led many lesser organizations to attempt excellence. But in fifteen years, the long line of troubled corporate contenders will lengthen to include companies that only concentrated on manufacturing excellence, that only perfected that slim area of opportunity, production. It’s not enough.

THE NEXT FRONTIER

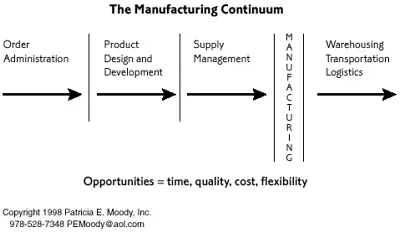

The biggest areas of opportunity lie ahead of and after manufacturing (see Figure 1.1). Look at the areas that feed and draw on the manufacturing function—all the places where idea transfer and development barriers stand in the way of ultimate customer fulfillment. These circuit breakers include traditional purchasing, MIS, order administration, accounting, middle management, senior management, possibly human resources, logistics, trucking, warehousing, design, design engineering, perhaps manufacturing engineering, returns, customer service, quality control, even teams—all areas where time is used up with no payback. And these waste areas lie especially thick at the second, third, and fourth tiers of the extended enterprise; the small- and medium-sized producers are one level—but a world away—from final assembly operations.

FIGURE 1.1 Opportunity Areas

Just as Motorola proved that quality is a given, that you can’t even be in the game with less than Six Sigma quality, so must we accept the inevitability of lean, perfect, agile, laboratory-like manufacturing processes. We already know how to do this. We know how to lay out efficient lines, how and when to introduce automation, and in what degree. We know how to select and develop and train and motivate our workforce. And we know how to measure—boy, do we ever measure! Any number you want, we’ve got.

THE LAST FRONTIER

Manufacturing, as this linear representation of the process from request to shipment shows, is the thinnest slice of the process, because in the past twenty years smart managers have taken much waste and labor out of the process. Indeed, the current focus on lean manufacturing is an obsession to drive waste and layers of complexity out of manufacturing, to strip it down to its bare essential processes for what is to come, apparently leaving few opportunities now for tweaking.

Further adding to the integration challenge is the fact that as manufacturing grew from Lowell’s semi-automated textile mills, to Intel’s clean room, robotic plants, various separate management areas—especially engineering, supply management, and production—developed their own noncommunicating systems, philosophies, metrics, and even career paths. These pieces will need to be reintegrated into a technologically complete process—not eliminated. They offer wide open and unique opportunities for innovation and custom, intelligent solutions that manufacturing innovators have not developed. In the 2020 enterprise, such functions as order administration, product development, and cash farming will blur into a single order communication process. Every bit of information that can be maintained for correct billing and product specification will be transmitted electronically in parallel to actual material processing. In effect, the opportunity time line will compress into a single input and output flow circuit diagram. With no more linear systems flows, the computer that moves the intelligence becomes transparent—what remains is innovation in design and clean, fast replication.

What we don’t have across our industrial landscape—including and especially along the extended value chain—is consistent, predictable, integrated easy excellence. That’s where the Technology Machine takes its rightful, advantageous place among the winners, carrying them to unthinkably high levels of performance, at unimaginably low costs.

Excellence must characterize every member of the entire value chain in metrics like 10X, a time-to-market improvement objective that drives organizations, particularly electronics, to develop and launch new products the way that grocers handle fruit that has a shelf life of three days, and Six Sigma quality. Look to the second, the third, and even the fourth tier for enterprise excellence in different technology areas.

Does that mean that customers must certify, “Baldrige,” or otherwise demand excellence out of their excellence partners? No, because we do not have time to wait for the inevitable result of that approach. It means, as our friends at Honda say, “Go to the spot.” Take excellence on-site.

EXCELLENCE IN THE YEAR 2020

Let’s extend our definition of excellence to enterprise excellence. Concentrate on the front end of the system—design and procurement, logistics, packaging, and customer service. These are the areas where the Technology Machine will take huge chunks of time and money out of the system, where it will make the biggest impact on product design and introduction, and where product design will become customer design.

FIGURE 1.2 Islands of Excellence

ISLANDS OF EXCELLENCE

In the year 2020 there will be two types of enterprises: the Island of Excellence, and all the rest. The Island of Excellence organization will do many things extremely well—manufacturing, real-time customer design of product and simultaneous production, or customer fulfillment. The workforce on the Island will be very special—specially selected, trained, motivated, and aware of their position as an elite corps. The organization at the Island will be deceptively simple—a lot happens with few ripples on the water, quietly and smoothly.

You might notice that things are in balance—functions that were, in previous decades, functionally siloed all seem blurred, or integrated, into a smooth flowing unit.

And the people are different. Diversity is not an issue. Although we see both sexes and many racial and ethnic “colors,” the overall pattern of the fabric of this organization—a well-selected, well-constructed, and simply laid-out quilt—is one of integration. From not too great a distance all personal differences blend into the overall design.

We do not see plaques bearing plastic corporate mission statements here. Instead, each inhabitant of the Island will have experienced a holistic, two-year apprenticeship program—where they learn to live the mission—for it would be a mistake to expect new members to find themselves quickly in this simple, but strong culture. People need time to adapt, and the security of knowing that they are trusted and expected to behave appropriately.

And what of the spirit? Well, it’s reassuring to know that the generation that followed self-indulgent Boomers and Generation X—the Reformation Generation—has returned to basic values. This generation will have none of their parents’ irresponsible neglect of the whole human entity—mind, heart, soul, as well as intelligence. The distinguishing characteristic of working on—rather being a member of—the Island is its integration of spiritual energy with physical and mental capabilities.

Inhabitants of the Island wear uniforms. The first fifteen minutes of each day are spent in light exercise, a form of Tai Chi. Sometimes associates sing or participate in an island-wide assembly. Many workers are engineers and many are “technicians,” but all have an integrated, common vision of how their daily work fits into the...