Improving Production with Lean Thinking

Javier Santos, Richard A. Wysk, Jose M. Torres

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

Improving Production with Lean Thinking

Javier Santos, Richard A. Wysk, Jose M. Torres

Información del libro

Unique coverage of manufacturing management techniques--complete with cases and real-world examples. Improving Production with Lean Thinking picks up where other references on production processes leave off. It is increasingly important to integrate and systematize lean thinking throughout production/manufacturing and the supply chain because the market is becoming more competitive, products are becoming more complex, and product life is getting shorter and shorter. With a practical focus, this book encompasses the science and analytical background for improving manufacturing, control, and design. It covers specific methodologies and tools for:

* Material flow and facilities layout, including a six step layout design process

* The design of cellular layouts

* Analyzing and improving equipment efficiency, including Poka-Yoke, motion study, maintenance, SMED, and more

* Environmental improvements, including 5S implementation

With real-life case studies of successful European and American approaches to lean manufacturing, this reference is ideal for engineers, managers, and researchers in manufacturing and production facilities as well as students. It bridges the gap between production/manufacturing and supply chain techniques and provides a detailed roadmap to improved factory performance.

Preguntas frecuentes

Información

1

Continuous Improvement Tools

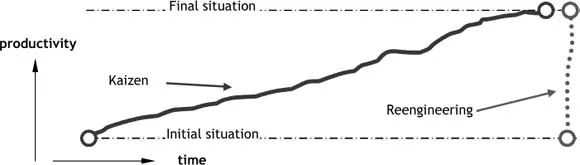

CONTINUOUS IMPROVEMENT

To standardize a method is to choose out of the many methods the best one, and use it. Standardization means nothing unless it means standardizing upward.Today’s standardization, instead of being a barricade against improvement, is the necessary foundation on which tomorrow’s improvement will be based.If you think of ‘‘standardization’’ as the best that you know today, but which is to be improved tomorrow—you get somewhere. But if you think of standards as confining, then progress stops.

IMPROVEMENT PHILOSOPHIES AND METHODOLOGIES

Índice

- Cover

- Contents

- Title Page

- Copyright

- Preface

- 1: Continuous Improvement Tools

- 2: Material Flow and Facilities Layout

- 3: Material Flow and the Design of Cellular Layouts

- 4: Equipment Efficiency: Quality and Poka-Yoke

- 5: Equipment Efficiency: Performance and Motion Study

- 6: Equipment Efficiency: Availability, Performance, and Maintenance

- 7: Equipment Efficiency: Availability, Quality, and SMED

- 8: Environmental Improvements and the 5S Methodology

- 9: Other Improvement Keys

- Appendix A: Problems

- Index

- Wiley End User License Agreement