1.1 Aluminium as an engineering material

Aluminium is the third most abundant element in the earth’s crust, and the most abundant metallic element. For the last 50 years, it has been second only to iron in its industrial use. Aluminium does not occur in an elemental state; rather it is always combined in a chemical compound. Its existence was not recognized until 1808, when an impure form was identified by Sir Humphry Davy in Britain. In 1825, Hans Christian Oersted of Denmark produced minute quantities of the metal,and two years later Freidrich Wöhler of Germany described a process for producing aluminium as a powder by reacting potassium with anhydrous aluminium chloride. In 1845, he determined its specific gravity thereby establishing it as a low-density metal.Thefirst commercial process for producing aluminium was developed by Henri Sainte-Claire Deville in 1854, using an improved version of Wöhler’s process. The metal was, however, still very expensive, and during the next 30–40 years numerous attempts were made to develop more economic processes whereby costs could be reduced. Developments during this period are described in an interesting book by Aldophe Minet (1902, 1905) published first in German in 1902 and then English in 1905.

The development of the present electrolytic process occurred almost simultaneously in 1886 by Charles Martin Hall in the United States and Paul L.T Héroult of France (i.e. the Hall–Héroult process). This represented a major advance, since it opened the way for the economical production of aluminium, which began in about 1890. One essential stage in the process was the extraction of alumina (Al2O3) from the ore bauxite, and an efficient method to do this was developed by Karl Joseph Bayer in 1888. A further essential factor was the availability since the early 1870 s of generators capable of supplying electricity on the large scales required for electrolysis. To this day, the Bayer and the Hall–Héroult processes have remained the most economical methods for the production of commercial quantities of aluminium, and are the mainstay of the primary aluminium industry.

1.2 The development of aluminium alloys

It is interesting to note that the potential for aluminium alloys as engineering materials was recognized well before it became an industrial metal. In early 1886, it had been stated that: ‘It has been generally held that the most useful field for this metal would be found in its alloys, many of which are possessed of valuable properties; but we incline to the opinion that the metal itself, should it become possible to produce it cheaply enough to enable it to compete in price with tin or copper for example, would find innumerable applications’ (The Manufacturer and Builder, 1886). Due to its very high cost, the early applications of aluminium were often limited to small- or high-value items made of alloys such as Al-Ag which were used in the manufacture of instruments for marine observations (such as sextants) and balance beams where light weight was highly advantageous. Various other high-value domestic items were also produced such as tablespoons, which were reported in 1879 to cost (US) $20/dozen or close to a month’s wages for a labourer of the time (The Manufacturer and Builder, 1879).

Well before the Hall–Héroult process was known publicly, the compositions of several engineering alloys had been investigated, including those of aluminium with varying contents of Fe, Cu, Zn, Sn, Au and Ag (e.g. The Manufacturer and Builder, 1877). As early as the 1870 s, alloys containing between five per cent and ten per cent Cu were reported as being suitable for castings as well as for working into sheet, wire and other wrought products (e.g. Lange, 1873). One particular composition within this range, which was known as alloy 12 (Al-8Cu), was used extensively at least until the late 1930s for castings in automotive, consumer and aerospace applications, including the engine of the Wright Flyer 1 in 1903 (for a photograph of Wright engine #17 from 1910, see Armistej, 2006). By the time the book by Minet (1902, 1905) was published, the mechanical properties of a range of aluminium alloys and processes employed for working them had been examined in greater detail. Even at this early stage, their potential use for castings and wrought body structures for the transport industry had been recognized. For example, the Paris exposition of 1900 featured a wide range of aluminium alloy castings including a number produced for the then fledgling automotive industry (Minet, 1902, 1905). Wrought sheet of an alloy Al-3Cu-0.8Sn, known as ‘partinium’ (Minet, 1902, 1905), had also been used extensively in the electric vehicle named ‘La Jamais Contente’ built by Rothschild Coach Builders. Driven by Camille Jenatzy of Belgium, this vehicle attained the first world speed record greater than 100 km/h (105.9 km/h) in 1899 (e.g. Furet, 2008).

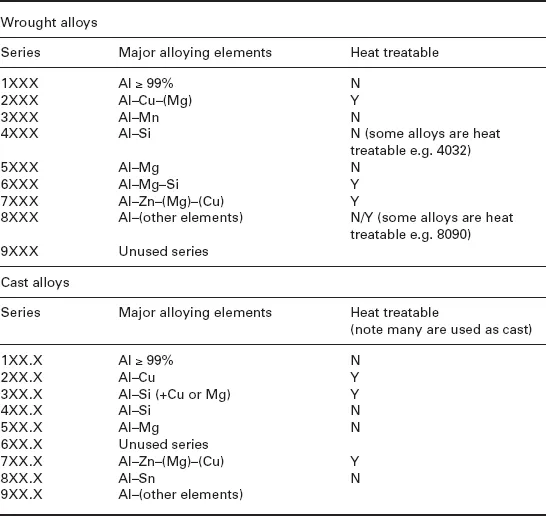

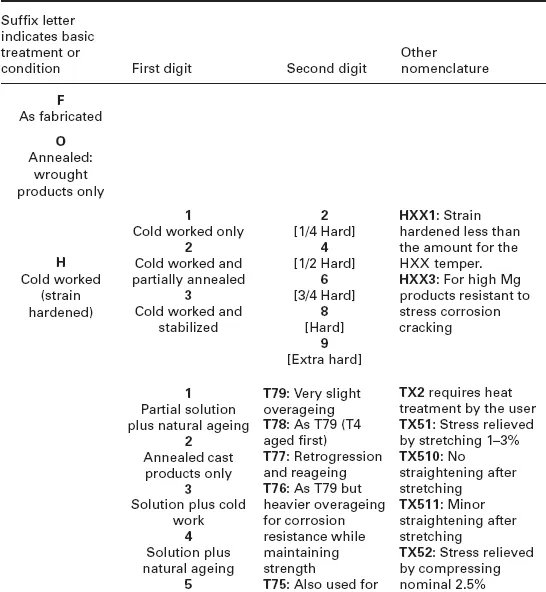

In 1906, four years after the publication of Minet’s book, Alfred Wilm of Germany discovered the basic procedure by which some aluminium alloys (i.e. the Al-3.5Cu-0.5 Mg-0.5Mn alloy that became known as Duralumin) could be heat treated. These techniques which involved precipitation (age) hardening are still used today, for strengthening a wide range of automotive and aerospace components (Cahn, 1984; Wilm, 1911). The basic technique developed by Wilm (a high-temperature solution treatment followed by quenching) was similar to that used previously for aluminium bronzes (Cu with 5–10% Al), as a way of softening the alloy so that it was easier to work at ambient temperature (The Manufacturer and Builder, 1881). The discovery of age hardening by Wilm is reported to be an extension of earlier patents related to the heating and quenching of aluminium (Cahn, 1984). Duralumin was instrumental in the development of the airship and aircraft industries and related Al-Cu-Mg alloys are still produced today. Examples of current wrought and cast aluminium alloys, and whether or not they are heat treatable, are shown in Table 1.1. Similarly, a wide array of procedures for heat treatment and thermomechanical processing has been developed, which are summarized in Table 1.2.

Table 1.1

The Aluminum Association alloy designation system*

*While the Aluminum Association wrought alloy designations are very widely used, there are no universal casting alloy designations in wide use. However, for any casting alloy, there are usually equivalent alloy designations from each different region.

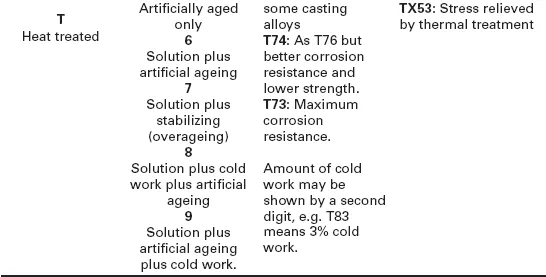

Table 1.2

Registered temper designations for aluminium alloys