eBook - ePub

Plastics in the Circular Economy

Vincent Voet, Jan Jager, Rudy Folkersma

This is a test

Partager le livre

- 300 pages

- English

- ePUB (adapté aux mobiles)

- Disponible sur iOS et Android

eBook - ePub

Plastics in the Circular Economy

Vincent Voet, Jan Jager, Rudy Folkersma

Détails du livre

Aperçu du livre

Table des matières

Citations

À propos de ce livre

We cannot imagine a world without plastics. Plastic products make our daily life safe, healthy and convenient. Besides all the benefits, the current plastics economy gives rise to environmental concerns with respect to fossil oil depletion and plastic waste accumulation. In a circular economy, however, plastics can be redesigned for reusability and recyclability. This book makes the topic of sustainable plastics approachable for students and career starters alike, describing the nature and chemistry of (bio)polymers as well as how to create a closed loop of plastic materials.

Foire aux questions

Comment puis-je résilier mon abonnement ?

Il vous suffit de vous rendre dans la section compte dans paramètres et de cliquer sur « Résilier l’abonnement ». C’est aussi simple que cela ! Une fois que vous aurez résilié votre abonnement, il restera actif pour le reste de la période pour laquelle vous avez payé. Découvrez-en plus ici.

Puis-je / comment puis-je télécharger des livres ?

Pour le moment, tous nos livres en format ePub adaptés aux mobiles peuvent être téléchargés via l’application. La plupart de nos PDF sont également disponibles en téléchargement et les autres seront téléchargeables très prochainement. Découvrez-en plus ici.

Quelle est la différence entre les formules tarifaires ?

Les deux abonnements vous donnent un accès complet à la bibliothèque et à toutes les fonctionnalités de Perlego. Les seules différences sont les tarifs ainsi que la période d’abonnement : avec l’abonnement annuel, vous économiserez environ 30 % par rapport à 12 mois d’abonnement mensuel.

Qu’est-ce que Perlego ?

Nous sommes un service d’abonnement à des ouvrages universitaires en ligne, où vous pouvez accéder à toute une bibliothèque pour un prix inférieur à celui d’un seul livre par mois. Avec plus d’un million de livres sur plus de 1 000 sujets, nous avons ce qu’il vous faut ! Découvrez-en plus ici.

Prenez-vous en charge la synthèse vocale ?

Recherchez le symbole Écouter sur votre prochain livre pour voir si vous pouvez l’écouter. L’outil Écouter lit le texte à haute voix pour vous, en surlignant le passage qui est en cours de lecture. Vous pouvez le mettre sur pause, l’accélérer ou le ralentir. Découvrez-en plus ici.

Est-ce que Plastics in the Circular Economy est un PDF/ePUB en ligne ?

Oui, vous pouvez accéder à Plastics in the Circular Economy par Vincent Voet, Jan Jager, Rudy Folkersma en format PDF et/ou ePUB ainsi qu’à d’autres livres populaires dans Tecnología e ingeniería et Ciencias de los materiales. Nous disposons de plus d’un million d’ouvrages à découvrir dans notre catalogue.

Informations

1 Towards a circular economy

1.1 History of plastics

Many consumer goods that we use in our daily life are made from plastics. Today, we cannot imagine a world that exists without these versatile materials. Plastics help to keep us safe and healthy, and they improve the shelf life of food products. They make our everyday lives convenient in many ways. Halfway through the last century, however, we hardly used any plastics. The availability of plastic materials was fairly limited as was the number of possible applications. How did plastics transform from being so rare to becoming all around us?

In general, plastics consist of large molecules, named polymers, mixed with additives such as plasticizers, colorants, or flame retardants that improve the properties of the final product. Polymer science is considered a relatively new field of study. Nevertheless, polymeric materials have been applied for many centuries. In fact, more than 3,000 years ago, the Olmecs, an ancient Mesoamerican civilization in Mexico, played their “pok-ta-pok” game with a ball made from natural rubber. They are believed to be the first to actually process polymers from nature. It was not until the 1840s that Charles Goodyear in the United States patented the vulcanization of rubber using sulfur. After this discovery, rubber was soon adopted for multiple applications, including tires and footwear. The first synthetic polymer that was not derived from plants or animals but from fossil fuels was invented in 1907 by Leo Baekeland. His phenol formaldehyde resin was unique due to its hardness and heat-resistant properties, and it was named Bakelite®, after his inventor.

In 1920, Hermann Staudinger published his paper entitled “Über Polymerisation”, in which he proposed that polymers are molecules with a high molar mass, composed of a large number of small building blocks. The fundamental understanding of this new class of materials, which Staudinger called macromolecules, lead to the development of a wide variety of new synthetic plastics and is therefore often considered to be the birth of polymer science. A few decades later, Staudinger was awarded the Nobel Prize in Chemistry for his pioneering work.

Today’s commodity plastics, such as polyethylene (PE), polyvinylchloride (PVC), polystyrene (PS), and polyamide (PA), all became commercially available in the 1930s (Fig. 1.1). The extensive needs of the military during the Second World War further increased the industrial growth of plastics, and other polymers were developed including polyester and Dupont’s polytetrafluoroethylene (PTFE), better known as Teflon®.

Figure 1.1 Timeline presenting the rise of the age of plastics.

Synthetic polymers, applied in plastics, rubbers, and fibers, became increasingly popular during the second half of the 20th century, when more and more products found their way to the market. Styrofoam™ was invented, and the polyethylene bag made its first appearance, as well as Tupperware®, developed by Earl Silas Tupper who cleverly promoted his air-tight polyethylene food containers through a network of housewives. In the late 1950s, LEGO® patented its block coupling–decoupling system, and Mattel unveiled the first Barbie doll. Later on, acrylic paints were developed and polyethylene terephthalate (PET) beverage bottles were introduced. By the end of the 1970s, plastics were the most common type of material worldwide.

Nowadays, polymers can be tailored with high precision to meet the requirements of modern society. Annually, millions of tons of plastics are being produced worldwide. The applications are diverse: from low-cost products such as clothing, food packaging, and children toys to high-performance plastics in composites used in spacecraft, mobile phones, membranes, and medical implants such as artificial heart valves. Synthetic plastics seem to last forever. Unfortunately, this advantage turns out to be a serious disadvantage with respect to our environment. Since most plastics decompose very slowly, if at all, plastic waste can stay in landfills for thousands of years. Even more concerning is the part that leaks into our ecosystem, like the (micro)plastics that find their way to oceans forming floating junkyards better known as plastic soup. These problems need to be addressed, and current efforts focus on (micro)biologically degradable polymers, industrially compostable materials, and the process of recycling plastics [1].

1.2 Introduction to the plastics economy

The largest fraction of industrial polymers is derived from petroleum. Crude oil that comes out of the soil contains a multitude of components: various hydrocarbons, mostly alkanes, cycloalkanes, and various aromatic hydrocarbons. In an oil refinery, the crude oil is separated into different components, and large molecules are broken down into smaller molecules. This is a process referred to as steam cracking. The petrochemical industry receives the refined oil and creates monomers through chemical reactions and polymers through polymerization reactions. Next, the plastics industry produces all sorts of products from those polymeric materials. The production process is schematically depicted in Fig. 1.2. Plastics are usually not unambiguous materials. There are many distinguishable types and numerous grades of plastics available on the market, each with its own characteristics, properties, and applications. Most often, plastics are designed for a specific application, by choosing the right combination of polymer and additive type, to meet the demands for that application in the most efficient manner.

Figure 1.2 Schematic production process for plastics from crude oil.

Plastics are produced in very large volumes. According to Plastics Europe, the association of plastics manufacturers in Europe, 359 million metric tons of plastics were produced worldwide in 2018 [2]. This enormous pile of materials equals 7,000 Titanic ships, or circa 35,000 Eiffel Towers. These plastics include thermoplastics, thermosets, elastomers, adhesives, coatings, sealants, and certain fibers. In past years, the global production capacities of plastics increased enormously. In contrast, only 1.5 million metric tons of plastics were produced worldwide in 1950.

The largest share of the plastics production volume is melt processable plastics, so-called thermoplastics. Polyethylene (PE, 32 %), polypropylene (PP, 23 %), polyvinyl chloride (PVC, 16 %), polystyrene (PS, 7 %), and polyethylene terephthalate (PET, 7 %) comprised 85 % of the total global production volume of thermoplastics in 2015. Assuming that the current world population is about 7.8 billion people (December 2019), this means that on average more than 46 kg of plastics are produced annually per capita of the world population. We can expect that the production volumes of plastics will increase even further in upcoming years. Some recent studies even predict that the total production volume will double in the next 20 years. It has been estimated that in total about 8,300 million metric tons of virgin plastics have been produced globally to date.

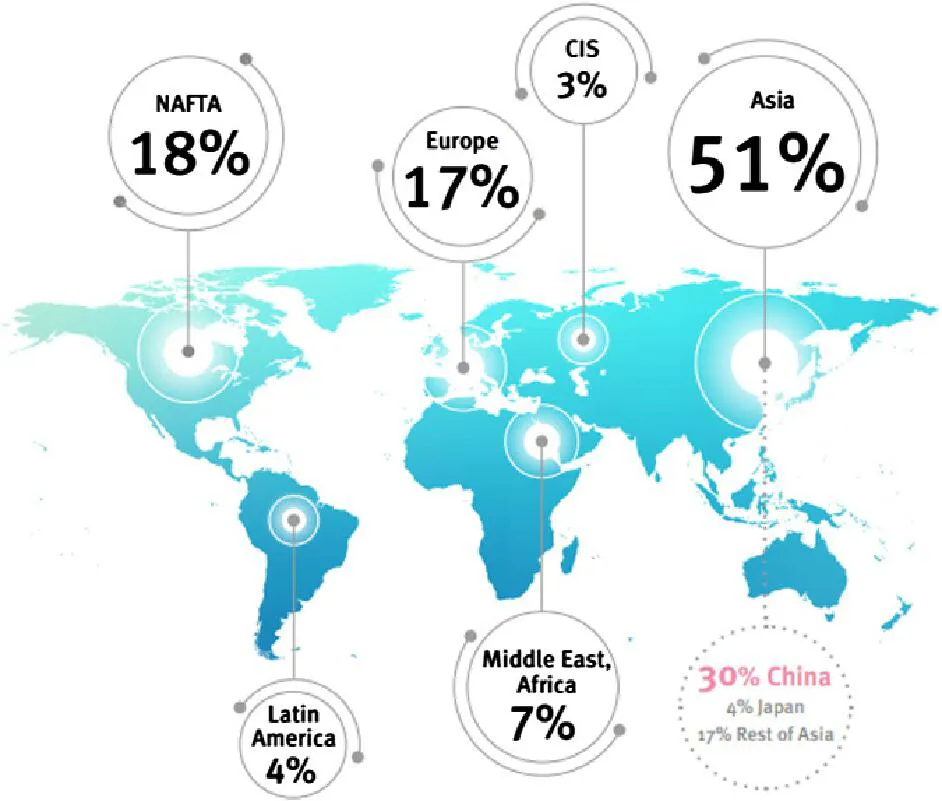

China is the largest producer of plastics in the world, producing 108 million metric tons in 2018, which equals a 30 % market share. As shown in Fig. 1.3, about half of the production volume of global plastics takes place in Asia, followed by North America (18 %) and Europe (17 %).

Figure 1.3 Distribution of the global plastics production in the world in 2018, according to Plastics Europe [2].

According to Plastics Europe, the total converter demand for plastics amounts to 51 million metric tons in Europe. The European plastic converter demand includes both thermoplastics and polyurethanes and some other plastics (thermosets, adhesives, coatings, and sealants). In terms of market segments, almos...