eBook - ePub

Injection Moulding

A Practical Guide

Vannessa Goodship, Vannessa Goodship

This is a test

- 416 pagine

- English

- ePUB (disponibile sull'app)

- Disponibile su iOS e Android

eBook - ePub

Injection Moulding

A Practical Guide

Vannessa Goodship, Vannessa Goodship

Dettagli del libro

Anteprima del libro

Indice dei contenuti

Citazioni

Informazioni sul libro

This revised 3rd edition details the factors involved in the injection moulding process, from material properties and selection to troubleshooting faults, and includes the equipment types currently in use and machine settings for different types of plastics. Since material flow is critical in moulding, the book covers rheology and viscosity. High temperature is also discussed as it can lead to poor quality mouldings due to material degradation.

Domande frequenti

Come faccio ad annullare l'abbonamento?

È semplicissimo: basta accedere alla sezione Account nelle Impostazioni e cliccare su "Annulla abbonamento". Dopo la cancellazione, l'abbonamento rimarrà attivo per il periodo rimanente già pagato. Per maggiori informazioni, clicca qui

È possibile scaricare libri? Se sì, come?

Al momento è possibile scaricare tramite l'app tutti i nostri libri ePub mobile-friendly. Anche la maggior parte dei nostri PDF è scaricabile e stiamo lavorando per rendere disponibile quanto prima il download di tutti gli altri file. Per maggiori informazioni, clicca qui

Che differenza c'è tra i piani?

Entrambi i piani ti danno accesso illimitato alla libreria e a tutte le funzionalità di Perlego. Le uniche differenze sono il prezzo e il periodo di abbonamento: con il piano annuale risparmierai circa il 30% rispetto a 12 rate con quello mensile.

Cos'è Perlego?

Perlego è un servizio di abbonamento a testi accademici, che ti permette di accedere a un'intera libreria online a un prezzo inferiore rispetto a quello che pagheresti per acquistare un singolo libro al mese. Con oltre 1 milione di testi suddivisi in più di 1.000 categorie, troverai sicuramente ciò che fa per te! Per maggiori informazioni, clicca qui.

Perlego supporta la sintesi vocale?

Cerca l'icona Sintesi vocale nel prossimo libro che leggerai per verificare se è possibile riprodurre l'audio. Questo strumento permette di leggere il testo a voce alta, evidenziandolo man mano che la lettura procede. Puoi aumentare o diminuire la velocità della sintesi vocale, oppure sospendere la riproduzione. Per maggiori informazioni, clicca qui.

Injection Moulding è disponibile online in formato PDF/ePub?

Sì, puoi accedere a Injection Moulding di Vannessa Goodship, Vannessa Goodship in formato PDF e/o ePub, così come ad altri libri molto apprezzati nelle sezioni relative a Sciences physiques e Chimie industrielle et technique. Scopri oltre 1 milione di libri disponibili nel nostro catalogo.

Informazioni

1 Introduction

1.1 The big picture

When the Hyatt brothers, John and Isaiah, built and patented the first injection moulding machine (IJM) in 1872, it is doubtful they could possibly have imagined the impact this invention would have on the world. It spawned a worldwide industry employing millions of people.

In 2013, plastic manufacturers generated over 373 billion US dollars (USD) in the US alone with the plastic industry employing 900,000 people there. The worldwide consumption of plastic materials rose from 245 million metric tonnes in 2008, to 311 million metric tonnes in 2014. China uses over a quarter of the world’s plastics, with this figure increasing year on year as manufacturing grows. Europe’s manufacturing base is the second largest global market consuming around 20%. The Chinese market is increasingly prominent across the entire plastics sector and China is currently both the largest producer of machines in the world and the biggest consumer of them, which drives the need for a plastic raw materials market as well.

IJM sales in China had reached a market worth 25.5 billion Chinese yuan [renminbi (RMB)] in 2013, and was expected to reach RMB30 billion by 2016.

The packaging sector accounts for the majority of the world market, with the automotive industry and the electrical equipment industry also both heavy consumers of plastic and injection mouldings. Other important markets for plastic materials are the construction industry and consumer products.

A major factor for the entire injection moulding industry (and manufacturing in general) has been the globalisation of the market. Like other industries, successful IJM manufacturers have kept pace with changes in global demand and moved to lower cost production plants in the world’s developing economies, such as China, India and Brazil. To adapt to the increased competition, the successful manufacturers are the ones that have been able to adapt, innovate and compete.

From these few facts and figures it can be seen that injection moulding is an extremely large and important manufacturing industry, but what is injection moulding?

1.2 Introduction to injection moulding

Injection moulding is one of the most commonly employed processes to produce plastic parts. It is a cyclic process of rapid mould filling followed by cooling and ejection. A variety of materials both plastic and non-plastic can be used as feedstock; however, the machine must be configured for the type of material used.

The material, which is generally available as grains or powder, is plasticised in an injection unit and injected into a clamped mould under high pressure (500–1,500 bar). The main advantage of injection moulding is it is a very economical method of mass production. Ready parts with tight tolerances can be produced in one step, often completely automatically and, in general, subsequent processing steps are not necessary. It is also possible to integrate different functions into one part to avoid the formation of different components that would be more expensive, and some of these more advanced and integrated processes are discussed in Chapter 10.

To guarantee a high-quality injection moulded part the following points have to be considered:

- The material has to be plasticised and injected carefully to avoid negative effects on the properties and characteristics of the material.

- The process settings (such as pressures and temperatures) concerning the machine and mould have to remain constant with regard to time and space.

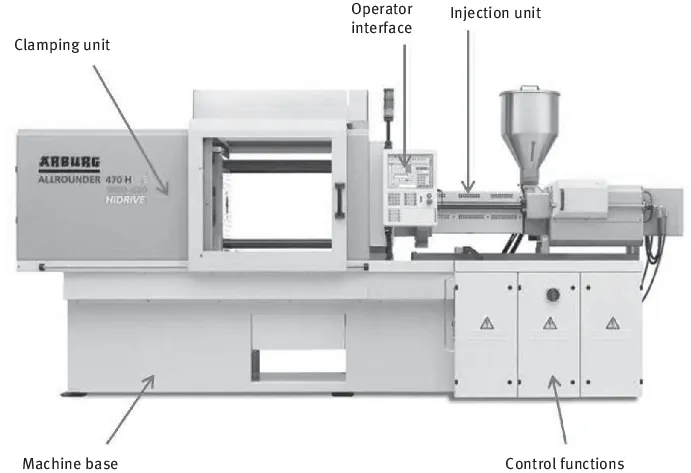

An example of a commercially available IJM is shown in Figure 1.1 and the basic parts that make up a machine are shown in Figure 1.2.

Figure 1.1: An injection moulding machine (IJM).

Figure 1.2: Basic components of an IJM.

The computer control unit allows the machine operator to control and monitor the process; control systems will be discussed in Chapter 5.

The purpose of the injection unit is to melt and meter the material into the tool; machinery will be discussed in Chapter 3.

The clamp unit holds the injection moulding tool and gives the required clamp force to hold the two sides of the mould tool together; tooling will be discussed in Chapter 4.

The machine base is powered by either electrical or hydraulic means, and houses the systems that drive the movement of the machine. Each machine has a certain ‘footprint’, which is the floor space it requires for operation.

1.3 The injection moulding process

During the injection moulding process, the mould and the plasticising area are separated from each other. The temperature of the plasticising area, i.e., the plasticising cylinder, is maintained at the same level as the processing temperature. The mould on the other hand, is kept cold enough for demoulding of the injection moulded part (thermoplastics), or warm enough for crosslinking (thermosets). The plasticised material is injected into the clamped mould. In an IJM, the clamping unit, which contains the mould and injection unit, is integrated. Completely automated production is possible if the mould is installed with a vertical parting line, which enables the parts to fall down and out of the mould after demoulding. IJM are more typically used for the processing of thermoplastics. There are two types of injection unit available: a piston injection unit and a screw piston injection unit (reciprocating); the reciprocating screw method is the most common. Only screw piston machines can be used for the processing of thermosets as without the screw, the dwell time would be too long and the risk of early crosslinking would be too high. The injection sequence for both types of machine now follows.

1.3.1 Piston injection unit

Injection sequence:

- Injection starts (clamped mo...

Indice dei contenuti

- Title Page

- Copyright

- Contents

- Preface

- 1 Introduction

- 2 Introduction to plastics

- 3 Injection moulding machinery

- 4 Injection mould tooling basics

- 5 Process control systems

- 6 Amorphous and semi-crystalline thermoplastics

- 7 Processing thermoset, liquid silicone rubber and ceramic materials

- 8 Guide values and processing instructions for the most important thermoplastic injection moulding compounds

- 9 Practical applications using injection moulding technology

- 10 Advanced processing techniques

- Abbreviations

- Index

Stili delle citazioni per Injection Moulding

APA 6 Citation

[author missing]. (2020). Injection Moulding (3rd ed.). De Gruyter. Retrieved from https://www.perlego.com/book/1449260/injection-moulding-a-practical-guide-pdf (Original work published 2020)

Chicago Citation

[author missing]. (2020) 2020. Injection Moulding. 3rd ed. De Gruyter. https://www.perlego.com/book/1449260/injection-moulding-a-practical-guide-pdf.

Harvard Citation

[author missing] (2020) Injection Moulding. 3rd edn. De Gruyter. Available at: https://www.perlego.com/book/1449260/injection-moulding-a-practical-guide-pdf (Accessed: 14 October 2022).

MLA 7 Citation

[author missing]. Injection Moulding. 3rd ed. De Gruyter, 2020. Web. 14 Oct. 2022.