![]()

CHAPTER 1

Introduction

1.0 GENERAL COMMENTS

Modern manufacturing methods dictate the use of material handling systems. Conveyors, a type of materials handling system, are an essential part of large-scale production and continuous processes. They are used in such diverse fields as agriculture, food processing, plastics manufacturing, and mining industries.

There are two basic methods used for moving materials: (1) nonpowered material handling systems and (2) powered material handling systems. Nonpowered systems use gravity as the motive force and include devices such as chutes and slides, which are the simplest and least expensive methods available. Nonpowered systems, however, require the starting point to be at a certain minimum elevation higher than the end point. In most material handling situations, this is rarely the case.

For moving material horizontally, vertically, over extended distances, or in a controlled fashion, powered material handling systems are required.

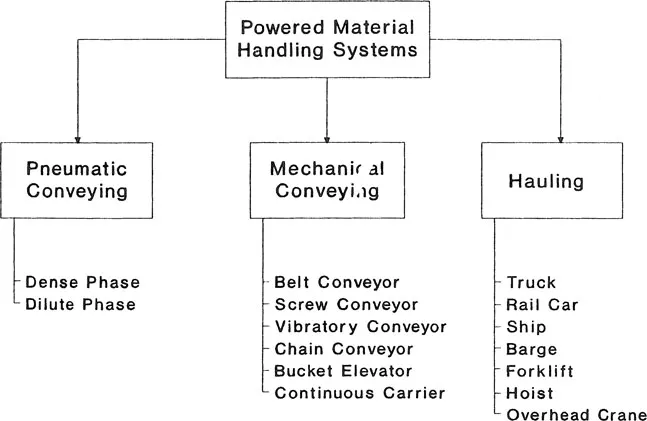

Figure 1.1 is a chart that breaks down the various types of powered material handling systems. Some examples of the various types of systems are also included.

This book specifically deals with mechanical conveyors. At this point, a definition of conveyor is in order:

Conveyors include all fixed and portable equipment capable of moving material in a continuous or intermittent fashion, between two or more points, along a fixed path. While the material may be delivered intermittently, the drive operates continuously. The movement of material can be horizontal, vertical, inclined, or any combination of the three.

This definition encompasses many types of elevating equipment and some of the new hybrid type conveyors. A bucket elevator is considered a conveyor because of its continuous drive and its ability to deliver material between two points. A skip hoist, on the other hand, is not considered a mechanical conveyor by this definition. While it can move material between two points, it does not have a continuous drive.

FIGURE 1.1 Various types of powered materials handling systems.

This definition is a variation of a definition from another source [1]. Different sources may adhere to their own definitions.

This book will also briefly discuss some of the mechanical conveyors that have feeding capability. An in-depth study of feeders, however, is beyond the scope of this book.

The equipment covered in this book will include

• belt conveyors

• screw conveyors

• vibratory conveyors

• chain conveyors

• bucket elevators

• continuous carriers

• various drives

1.1 CONVEYING AND MATERIAL HANDLING

Conveying is a single element in the greater spectrum called materials handling. A common definition of materials handling is

Materials handling is the art and science involving the moving, packaging, and storing of substances in any form [1].

Another definition from the same source is

Materials handling is the creation of time and place utility in material.

Materials handling includes every consideration of a material except the processing operation. Materials handling is, however, an integral part of many continuous processes. Some conveyors can provide minor processing functions such as heating and cooling, but this is supplementary to the primary materials handling function.

Materials handling can be broken down into more specific disciplines, which include

(1) Conveying deals with the movement of bulk solids in fixed paths.

(2) Feeding is the accurate control of material flow necessary for efficient conveying and processing. A feeder delivers a controlled flow of material from a storage device.

(3) Unit handling deals with moving objects both in fixed and nonfixed paths. A unit can be a bolt, a box, or a loaded pallet. In some applications, unit handling may overlap with conveying. Unit handling, however, may also deal with such diverse equipment as lift trucks and cranes. Conveyors used specifically for unit handling will not be covered in this book.

(4) Packaging is the science of controlled portioning of bulk materials and unit objects. Packaging can be broken into industrial and consumer types. Industrial packaging deals with portioning into useable volumes and providing protection during storage and transport. Consumer packaging also provides the same function as industrial packaging, but with the added element of presentation for consumer appeal.

(5) Storing deals with the accumulation and storage of large quantities of a bulk solid. Materials are stored in such devices as hoppers, bins, and silos. A special science has evolved with the problems encountered in storing materials.

(6) Warehousing covers receiving, storing, shipping, and scheduling of unit loads.

(7) Carrier handling and transport concerns the loading, securing, transporting, and unloading of bulk materials and unit loads. This may include such devices as trucks, rail cars, barges, planes, and ships.

While the primary topic of this book is mechanical conveying, in most conveying applications, one is likely to encounter one of the other aspects of materials handling listed above. If the reader is interested in the greater topic of materials handling, he should consult one of the many books written on the subject, which saw a great amount of interest and development in the years following World War II.

1.2 THE MATERIAL HANDLING PROBLEM

The selection of a conveyor is basically a material handling problem. The solution to one material handling problem may just create another material handling problem. A proper analysis should look at what effect adding or changing one component will have on the whole process.

A materials handling problem is an engineering problem and should be handled as such. To know “how” to convey something, you must first answer the questions “what, where, when, and why” [1].

A successful solution to a material handling problem is achieved through the use of knowledge and experience. The experience is gained in the specific industry in which the person is employed. For example, material handling in the mining and pharmaceutical industries is a different experience in each industry.

The experience may vary even between companies in the same industry. Often, a company will only use specific types of equipment, the selection being based on past successes and failures, or a desire to standardize equipment. This practice is acceptable and even recommended, as long as one remembers that each type of conveyor has its proper range of uses.

Successful application of a conveyor and experience gained in this field is a process learned by trial and error. There is no quick-fix chart or equation to solve all problems related to conveying and materials handling.

The first requirement for a person to select a conveying system is to have an understanding and familiarity of the specific process to which the equipment is to be applied. This knowledge is invaluable and may make the difference between a successful application and a failure. It is the small neglected detail in the process or the conveyed material that can lead to a system plagued with problems and unexpected downtime.

To select and apply a mechanical conveyor, a person should possess the following skills and abilities:

(1) A working knowledge of the main parts and assemblies, as well as the operating characteristics of the various types of mechanical conveyors

(2) A knowledge of the advantages and limitations of the various types of conveyors

(3) Familiarity of the various makes of each type of conveyor and the ability to discuss intelligently the differentiating aspects of each make, including a working knowledge of manufacturer’s catalogues and of sources for additional information

(4) The ability to make calculations and estimates relevant to the capacity and sizing of the various types of conveyors

(5) The ability to obtain and compare quotes from different manufacturers based on the estimates determined

(6) The ability to make a selection decision based on the preceding five points and to predict and counter any adverse effects caused by the material or the conveyor

(7) The ability to prepare the details of the installation of the new equipment. This may include layouts, surveys, installation schedules, standards, and other information

(8) The ability to familiarize oneself with the new equipment operating, training, safety, and maintenance procedures, which is necessary for proper operation of equipment and future troubleshooting

The primary selection of a conveyor may appear to be a daunting task considering the many choices available; however, with only a rudimentary knowledge of operating ranges, limitations, and advantages, the primary selection process is, in fact, simple.

The selection process can be further simplified by first eliminating those conveyors that are not suitable. Some of the operating characteristics of the various conveyors are very different, so it becomes apparent what conveyors are suitable for the specific task.

The difficulty in a materials handling problem lies in the material itself. Every material has its own unique set of characteristics that will affect the way it behaves on the various types of conveyors. Properties such as stickiness, abrasiveness, and lump size, to name a few, all affect materials handling characteristics.

Not only must you ask “How will material affect the conveyor?” the reverse scenario of “How will the conveyor affect the material?” must also be considered. Friability, purity, and hygroscopicity are examples of properties that may be affected as the result of a material being conveyed.

A successful application of a conveyor will consider all potential problems and provide reasonable countermeasures in the design stage. This is where experience plays a role. Persons who have already solved such problems are obviously most suited to solve them again. This experience may come from the in-house handling specialist, a consulting engineer, or the sales engineer vending the equipment. When dealing with the latter two, it is advisable to obtain references or a list of similar projects completed.

1.3 EQUIPMENT SPECIFICATIONS

After the conveyor type is selected, the next step is to prepare specifications for which bids are to be based on. Typically, the specificati...