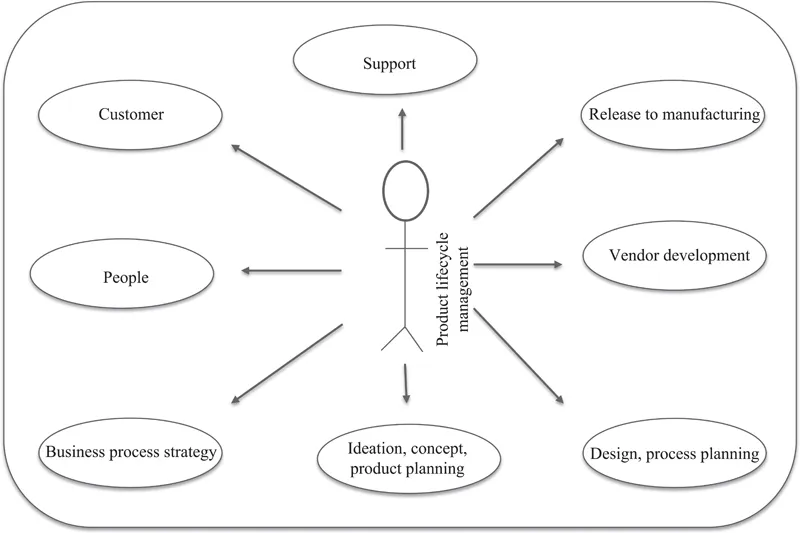

Product lifecycle management (PLM) is a familiar worldwide expression amongst the different manufacturing markets for the process by which a product moves from design through manufacture into the market. The key objective of PLM is to bring together the details, process other than persons attached with the lifecycle of a product within the enterprise. PLM cares for design data in enhancement to processes, constructs and also similarly regulates the cost of product records and additionally store products in a digital documents data source. PLM helps in recognizing product compliance, automates business process through process streamlining and monitoring. It controls multi-user product collaboration over and above availability, throughout the substantial enterprise. Understanding the different capabilities of PLM modules is a vital activity. Enterprises should be proficient in advanced manufacturing, which requires to integrate PLM system and acquire integrated data throughout the supply chain to achieve success. CAD data along with PLM quickly shares and additionally visualizes product details with essential decision makers in a selection of divisions, from engineering to excellent quality control.

Execution of a PLM system will unquestionably be unique to each enterprise, there are core PLM fundamentals that will regularly remain similar. PLM can be deemed both as an information strategy and as an enterprise approach. As an information strategy, it builds a meaningful data framework by combining systems. As a venture strategy, it allows global enterprises function as a solitary team to design, build, manufacture, support and obsolescence for products, while recording best lessons and methods discovered in the process. It encourages the enterprise to make combined, information driven choices at every phase in the product lifecycle. While information includes all mediums – digital and other formats, PLM is largely about managing the digital representation of product information. Based upon individual experience for many years, PLM options can sustain a broad series of products. Examples consist of manufactured parts/products, not limited to such as vehicles, computer systems, electrical home appliances, smart phones, and so on. Numerous products today additionally contain software, firmware, on top of digital components whose information should be taken care of. Some enterprises have long-lived possessions that require to be handled such as utility distribution networks, for example, power, telecommunications, oil and gas, and so on. Enterprises across several commercial markets have efficiently used PLM solutions to handle part/product information throughout the lifecycle for every one of the products manufactured.

The PLM view have improved from handling mainly the mechanical aspects of a product interpretation to consist of the electronics together with software application aspects that have become a better section of numerous products. That expansion remained to push the understanding of what blueprint is incorporated. PLM includes the management of all product-related information from demands, design, deployment, and release to manufacturing. This information ranges from presenting demands, product specifications, and inspection guidelines, to maintain setup information. PLM facilitate products information from various authoring tools and other systems to develop product planning. At the same time, the lifecycle began to include production-focused features with product data information.

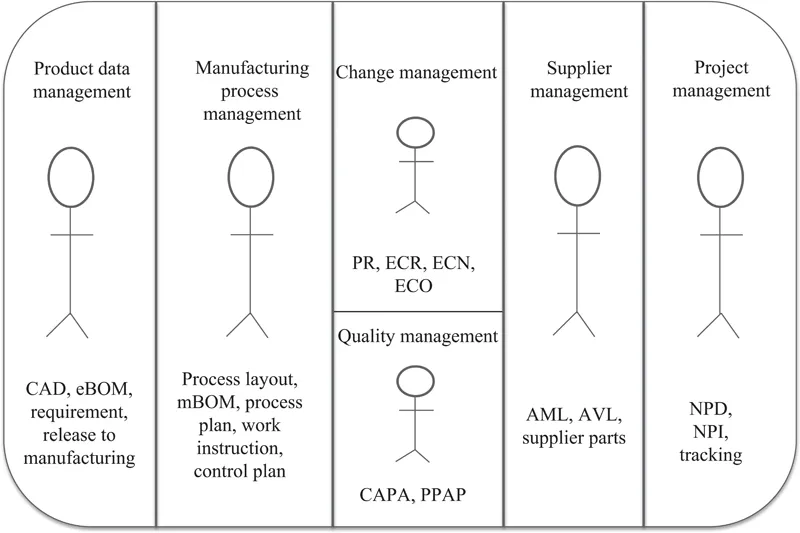

Today, PLM encompasses significant areas of process that includes not only programs but also projects with product data management. It comprises of the procedures required to design, develop the product and manufacture in the shop floor and decommission it at the end of its life. PLM utility specify, perform, gauge, and take care of the vital product-related business process. Product data along with functional process strategies are considered a fundamental component of PLM.

PLM FACILITY IN AN ENTERPRISE

To create new products, enterprises need a way to organize each of the associated data. From design sketches, concepts, notes to manufacturing process instructions for manufacturers, enterprises require a main repository for the dynamic information. PLM has actually ended up being essential as the single resource of reality for managing all elements of the product from preliminary development right through product retirement. PLM is the business process automation technique which is used to gather information, people, and process in touch with the lifecycle development of a product. Product development processes and productivity are completely connected and also have a direct impact on the manufacturer’s capacity to generate continual company growth. PLM integrates individuals, information, procedures in addition to legacy systems and provides product structure for enterprise and their extended enterprise. At an ever-increasing price, manufacturers have actually pertained to PLM as the prospective solution. Doing this accordingly involves numerous benefits such as lesser manufacturing errors, fewer cycle versions, and inevitably enhanced price to market. As PLM emphasize itself with the entire lifecycle of a product, from conception to customer, it is preliminarily important to recognize the concept of the product lifecycle along with the process. PLM describes the enterprise Bill of Material (BOM) and also furthermore implied alterations concerning the BOM, in enhancement to maintain the background of all previous product development ranges. PLM information is typically developed to take care of engineering along with all cross-functional team (CFT) members of the new product development (NPD) as well new product introduction (NPI) group.

PLM – A business strategy approach helps to share product information across the NPD/NPI team members, and leverage business knowledge for the development of products from dawn to dusk across the extended business.

PLM develops an incorporated digital platform to:

• Maximize collaboration along the lifecycle throughout enterprises.

• A single source of product management system to sustain varied information needs, to guarantee that the suitable individuals see the ideal product information at the correct time, in the correct context.

• Make the most of the lifetime worth of manufacturers, business product profile.

• Drive top-line income through repeatable procedures.

Businesses that are seeking to get a competitive advantage will do so by boosting their products and streamlining their processes. PLM solutions have actually confirmed to be expensive and too comprehensive besides challenging to take account of existing practices. Why do these solutions, which should be making things much less complicated, generally fail? Have a perfect result as PLM is most likely to aid product design and obtain their computer-aided design (CAD) files regulated, process engineering change orders (ECOs) quicker, increase component reuse, and so on but what will the overall company effect be? By carrying out a PLM system, business can simplify and also reduce each stage of the product development process, which is considered as a crucial success variable. Recognizing the difference in addition to greater possibility for PLM that how it is most likely to add worth to enterprise. An efficient PLM program, with well-defined connected campaigns and a purposeful carrying out plan, sets the ground for an effective transformation.

Establish authorization of PLM based on the roles as per NPD team, setup certain level of access policies for usage of the application and administration, from individuals to administrator who will be utilizing PLM in the office. The efforts demonstrated in PLM are to facilitate training, provide proper access to customer collaboration in the NPD/NPI process as very early as possible. Acknowledging that there could be obstructions along the road leading to PLM and correspondingly all kinds of stakeholder need to manage including leaders, enrollers, agents, champs, blockers, and accepters. Success is achieved by engaging and taking over barriers over these members, or finding out simply exactly how to make it despite them. Decision makers within the enterprise frequently look towards innovation to overrule these challenges.

PLM data will transfer straight to various other legacy systems and alert the product managers, creating even more specific details in addition to forecasts to the production planning control members. Integrating various manufacturing systems also practically eliminates the opportunity of inconsistencies existing in between them. With a lot more details concerning your process at the fingertips, it helps a lot additionally to easily determine feasible places for improvement. By encouraging information-sharing and communication between departments, system grouping can influence collaboration between departments and thus, will result in unexpected solution rework.

VALIDATE THE COST-EFFECTIVE INVESTMENT

PLM was constricted to designers for protecting design information. As products end up being much extra difficult and additionally technically advanced in the period of the Internet of Things (IoT), PLM must connect to facility, connected products which consist of mechanical electrical components, software program application, digital devices into BOM that attach with various other products, services, social collaboration of things exchange of information by means of mobile innovation within and extended business process in PLM to utilize single source of truth.

In addition to the needs pointed out, I now add the following few factors as well.

• Prompt PLM training to business stakeholders will certainly make PLM establishing dynamic and also it will connect the space between the individuals and the PLM professional.

• Quarterly business review to obtain a much deeper understanding of the solution in addition to future approaches to plan PLM roadmap.

• ROI calls have to be established.

PLM starts at the concept phase where quality, trustworthy parts with foreseeable, lengthy lives are chosen. Once the specification and validation of the product begins, all vital components are securely regulated through an enterprise business process. PLM includes all the critical areas of product design and development of data, along with supplier, change management, and so on. This makes it possible for the enterprise to address the core area of robust product development.

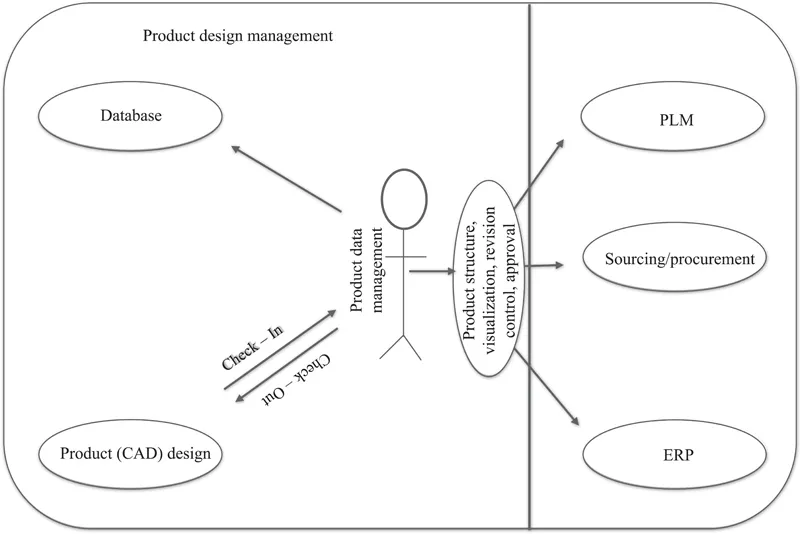

Product Data Management (PDM) – A system utilized throughout product design to shop and also obtain information to make sure that the details are intact throughout the life cycle of an item. When they need it, it benefits the usage of simultaneous engineering while maintaining control of information and also dispersing it immediately to the individuals who need it.

The PDM system is utilized during product growth to store and also obtain information to see product details and consistency throughout the life cycle process. When required by the cross-functional team, it benefits by using simultaneous design while keeping control of information and spreading it quickly to the people who need it. PDM was particularly developed to be extremely easy to execute, easy to utilize, budget-friendly for midsize to small manufacturers. PDM aids enterprise in a method to manage CAD data. Traditionally, this was a solitary intranet server taken care of within the enterprise. People can access records from throughout the geography precise like that of PLM. PDMs benefit variation control and normally utilize a check-in/check-out method. Every document gets “had a look at” when it is being modified. When it is being changed no person else can modify that document. When it is done being modified, it obtains “taken a look at” back into the vault for somebody else to change. Every change is tracked, due to the fact that the variant control is streamlined, it is straightforward to return to a previous version. PDM is the core of PLM.

MANUFACTURING PROCESS MANAGEMENT

Manufacturing process management (MPM) defines a concept of applying enterprise business process management tools to the locat...