eBook - ePub

Materials

Alan Everett, C. M. H Barritt

This is a test

Share book

- 272 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Materials

Alan Everett, C. M. H Barritt

Book details

Book preview

Table of contents

Citations

About This Book

A well-known and respected standard reference, this fifth edition provides a thorough treatment of the properties of building materials and their manufacture, both on-site and in the factory.

Frequently asked questions

How do I cancel my subscription?

Can/how do I download books?

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

What is the difference between the pricing plans?

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

What is Perlego?

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Do you support text-to-speech?

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Is Materials an online PDF/ePUB?

Yes, you can access Materials by Alan Everett, C. M. H Barritt in PDF and/or ePUB format, as well as other popular books in Tecnologia e ingegneria & Ingegneria edile. We have over one million books available in our catalogue for you to explore.

Information

1 General properties

Some properties, which relate to certain materials only, are considered in other chapters.

Properties which relate to materials generally are dealt with in this chapter, ie:

- Density and specific gravity

- Strength

- Optical properties

- Electrical properties

- Thermal properties and insulation

- Acoustic properties

- Deformations

- Deterioration

- Appearance

1.1 Density and specific gravity

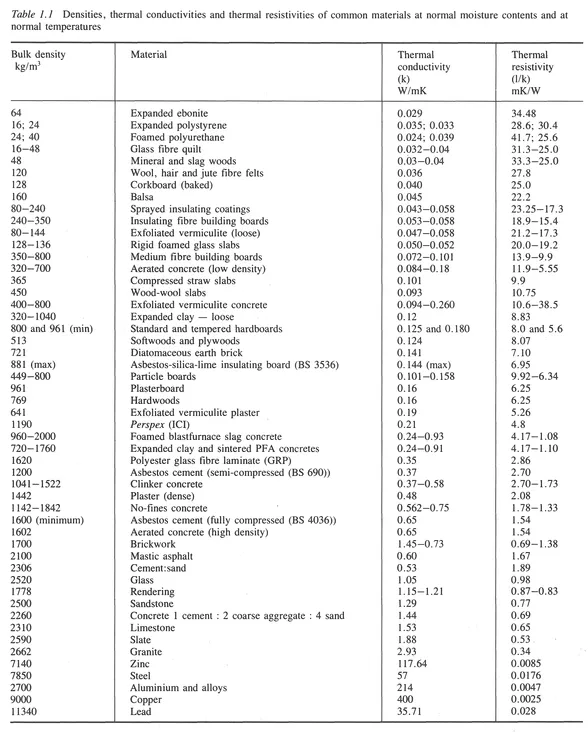

BS 648 Schedule of weights of building materials is a useful reference for calculation purposes. Table 1.1 gives densities for many materials in kg/m3, and others are given at the appropriate points in the text.

Specific gravity is a ratio of the density of a substance at a given temperature to the density of water at 4°C.

1.2 Strength

Materials must be capable of safely supporting their own weight and any applied loads without distortion which would reduce the efficiency of a structure, or be unsightly. Strength properties are defined on this page and values are given for a range of materials on pages 150—51.

When a material is said to be 'strong' it is its strength in tension which is usually referred to, but it is often necessary to know its strength properties in compression, shear and torsion. Also, strength properties vary with the rate and frequency of loading and, in non-homogeneous materials, with the direction of loading. Strength properties are further influenced by the moisture content of materials such as timber and the temperature of materials such as plastics. Absorbent materials are usually tested when wet to allow for loss of strength in that state.

Materials which are subjected to a force are said to be stressed and the change in shape is known as strain (cause and effect). In elastic materials up to an elastic limit strain is proportional to the load applied and they recover their original shape and size when the load is removed.

Materials, such as mild steel, which suffer a relatively small amount of strain when subjected to a given load are said to be stiff or rigid, a property which must not be equated with breaking strength. Thus aluminium alloys which are as strong in tension as steel are far less rigid.

With increasing load, at a point which is not always clearly defined, materials cease to be elastic and become plastic and undergo permanent distortion. Materials which do this to a high degree are ductile as distinct from brittle materials. Ductility generally decreases with strength in tension.

In varying degrees, materials undergo slow plastic deformation or creep, under a constant stress. Steel has very small creep at normal working stresses and temperature, but in a year or two even a small load increases the deformation of a concrete member as much as three times the initial elastic movement.

1.3 Optical properties

Some reference is made to this subject under Glass, chapter 12.

1.4 Electrical properties

The reader is referred to MBS: Environment and Services, chapter 15.

1.5 Thermal properties and insulation

British Standards concerning thermal insulation include:

BS 8207 CP for energy efficiency in buildings which sets out briefly principles and criteria for energy design.

BS 874 Methods of determining thermal properties, with definitions of thermal insulating terms.

BS 3533 Glossary of thermal insulation terms.

BS 3958: Parts 1—5, Thermal insulating materials describes various types and forms of preformed insulation.

BS 5803:Parts 1—5 deal with mineral and cellulose fibre insulation in pitched roof spaces in dwellings.

Heat is lost from buildings by ventilation — both intentional, eg open windows and flues, and accidental, through gaps around doors and windows. Heat is also lost through floors, walls, roofs and closed doors and windows — see BRED 190.

Heat losses and gains are achieved by:

Cavities in structures and components

Insulation improves with sealed cavities up to an optimum width of around 20 mm.

Cavities in external walls can be filled with insulating materials.

BS 8208 is a Guide to assessment of suitability of external walls for filling with thermal insulants. Part 1 deals with walls of Existing traditional cavity construction up to 12 m high.

BS 6676, Parts 1 and 2, is Thermal insulation of cavity walls using man-made mineral fibre batts (slabs).

Cavities in walls were first introduced to stop water penetrating, and this benefit can be retained by leaving a 20 mm gap between batts and the external masonry leaf.

BRED 277 deals with Built-in cavity wall insulation for housing.

Cellular materials

All materials accord some resistance to heat transmission, but those with small and discontinuous voids are most effective. Such insulating materials tend to be lightweight and weak, eg cork.

Specific insulating materials are listed in the index to this volume.

Thermal conductivity

Thermal conductivity (k) is a measure of the rate of heat transfer through unit thickness and area of a material from FACE to FACE (not from air to air). It is expressed as:

| heat units transmitted in unit time | watts (J/s) |

| through unit thickness | m |

| over unit area | m2 |

| with unit temperature difference between the faces | K |

| ie | W/mK1 |

Kelvin (K) is used for unit temperature difference measurement as it is the difference between one given temperature and another, whereas Celcius (C) is the difference between zero and a given temperature.

Table 1.1 lists some common building materials in order of increasing thermal conductivities (k) and decreasing resistivity (1/k). The Chartered Institute of Building Services Engineers Guide is a source.

The k-values of materials vary with density, in the examples quoted from 0.029 to 400 W/mK with corresponding variations in density from 64 to 9000 kg/m3. Conductivity values also vary with temperature, porosity and moisture content. With a moisture content of 20 per cent, volume by volume, most building materials transmit between two and three times as much heat as they do when they are dry. Hygroscopic materials such as timber vary in moisture content with the relative humidity of the atmosphere. Common sources of dampness in materials are defective copings and damp proof courses and condensation.

Thermal resistivity of materials

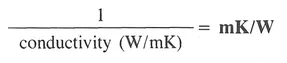

Thermal resistivity (1/k) is a measure of the resistance to heat flow through unit thickness and area of a material from FACE to FACE and is the reciprocal of the conductivity value. Thus:

Reflective materials

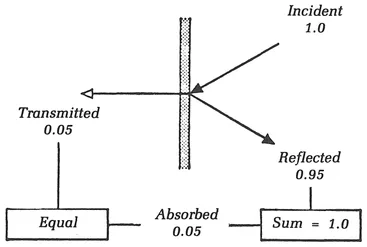

These materials have high reflectivity and low emissivity, eg aluminium foil, see figure 1.1. It will be noted that a very thin film of materials with high conductivity can be a useful insulator.

Any two bodies facing each other exchange heat by radiation, the rate of emission and absorption depending upon the nature of their surfaces, and the temperature difference.

Figure 1.1 shows the mechanism of radiant heat transfer.

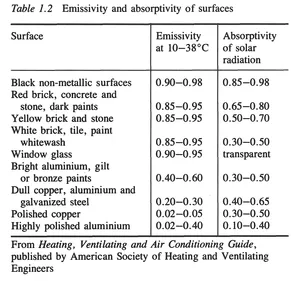

Table 1.2 gives emissivities at normal temperatures and absorptivities of solar radiation of various surfaces.

It will be seen that highly polished aluminium is the most effective reflector of both normal temperature and solar radiation. Differences in colour are not important at normal temperatures but white is a good reflector of solar radiation and even better than aluminium which has become dulled by oxidation. Thus, the thermal resistance of an unventilated cavity 19 mm or more wide is nearly doubled if it is faced on one2 or both sides with a surface of low emissivity such as shiney aluminium foil. Resistance is further increased if foil forms an airtight division between two cavities each at least 19 mm wide. White surfaces are particularly effective and in keeping mastic asphalt and bitument felt roofings cool in summer.

Figure 1.1 Radiant heat transfer of typical aluminium foil at normal temperature

Thermal transmittance

Thermal transmittance (U) is the rate of heat transfer through a construction from AIR to AIR expressed as:

| heat units in unit time | watts (J/s) |

| over unit area | m2 |

| with unit difference in temperature from air to air | K |

| ie | W/m2 K |

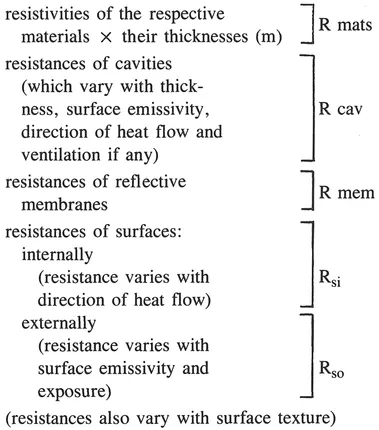

Thermal transmittance is the reciprocal of the sum of all the thermal resistances offered by a construction from air to air, ie:

BRE Digest 108 gives: Standard U-values.

Building Regulations Approved Document L gives two methods for demonstrating how heat loss can be limited. The first, and simplest, is an elemental approach and the second is by calculation using one of two procedures.

The elemental approach states that the requirements of the Regulations will be met if the relevant elements of construction have a U-value not exceeding those shown in table 1.3.

Simple alternatives to these values in respect of dwellings only are given as:

- if half the total window area is double glazed, the walls can have a higher U-value of 0.6 W/m2K,

- if all the windows are double glazed, the roof can have a U-value of 0.35 W/m2K and the ground floor can be uninsulated,

- if the ground floor is insulated to give a U-value of 0.35 W/m2K the roof insulation can be changed to 0.35 W/m2K.

Pattern staining

Dirt in air ...