![]()

1 Introduction

Purchasing is not new; it has been around since the invention of money, and it is even older if we include bartering as its forerunner. Consequently, we are all familiar with it. Further, we all buy goods and services if we consider the domestic as well as the business context. However, we may not be fully aware of the contracting processes involved. Fortunately, in the domestic environment we are protected by the ‘Sale of Goods’ act. In the business context the game is different. Companies are considered as being able to look after themselves, put procedures in place and have professional advisors. The Romans had a saying, ‘caveat emptor’ (let the buyer beware) which is still part of our legal philosophy. As a consequence, organizations are careful to ensure that trained personnel carry out buying. Further, the purchasing specialists have been ‘authorized’ by the organization to form contracts on their behalf. However, even then, they may not be fully aware of the implications of the contracts involved.

This book is written from a project manager’s perspective but it is not a book on project management as such. Since buying goods and services is an integral part of most project processes, there will be many instances where project management methods will be discussed. However, a specific point of view will be taken, and detailed debate over project management philosophies will be avoided. Further, the procurement manager on a project is, after all, the manager of a portfolio of smaller projects. Consequently, understanding the context in which purchasing takes place is essential if the process is to be managed effectively.

The book is intended for those who wish to improve their knowledge of the purchasing process from a project perspective. After being involved in education and training for 20 years I have concluded that you can never be sure where people lack the necessary knowledge or experience. Consequently, the book assumes little prior knowledge. However, it endeavours to extend the knowledge of experienced buyers and other project personnel.

When purchasing goods and/or services one is involved in a contracting process, and this is the focus of the book. However, the process involved in the suppliers’ or contractors’ tendering phase is not covered in detail. The intent is to focus on principles rather than the particular peculiarities of individual business or industry sectors. Nevertheless, some references to proprietary processes will be used to demonstrate the extent to which the principles are varied.

Every effort has been made to make each chapter stand, or to be read, alone so that they are not dependent on knowledge from other chapters. Nevertheless, a reference to the appropriate chapter has been included where a topic is integral to the subject under discussion but is covered in more detail elsewhere. Occasionally, some phrases are reiterated where the issue is of importance to the subject under discussion.

Each chapter deals with the general before discussing the particular, and deals with both the purchasing of goods and services. The buying of goods is used as the ‘generic’ element applicable to both aspects. Contracting for services is used to demonstrate the more complex issues involved.

Experiences and examples have been included to demonstrate the diversity of issues that the project manager can be involved with, but also to transpose the theory into real life.

A distinction is made between Procurement and Purchasing. Purchasing is restricted to the act of buying the goods and services; whereas procurement is managing the whole process from buying to delivery of the goods.

A term that is used more and more these days, in project organizations, to distance the procurement function from the more narrow purchasing process is Materials Management. It does focus more on what a project needs, but it is to all intents and purposes, procurement with material control and inventory control added on.

A section explaining additional terminology used appears at the end of this chapter.

PROCUREMENT

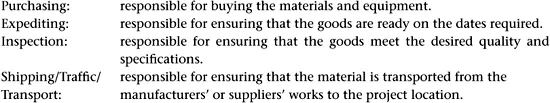

A procurement department usually consists of four or five groups:

A contracts group responsible for formulating the subcontracts for services, for execution and administration by the installation or construction department, is also required. In some organizations this group is part of procurement, for example, for formulating orders for design services. In some a separate contracts group is established, and in others the formulation of contracts is part of the executing department, for example, for installation and construction services.

The purchasing of ‘goods’ comprises both materials and smaller equipment, and will involve placing orders using a company’s standard contract terms. Large equipment and packages will, more than likely, involve installation and commissioning services. Contracting for design, installation or construction services often involves the provision of materials as well as services. As a consequence, they will involve more specialized and detailed contracts.

A procurement department or group on a project will be headed by a project procurement manager, supervisor or coordinator. The project procurement manager’s role is to coordinate purchasing activities and the interfaces with the other functions within the group. They are also responsible for coordinating with other disciplines such as design, installation, accounting and legal departments. They implement the procurement plan within the overall project execution plan and control the procurement schedules. They ensure that decisive action is taken should problems arise and maintain relationships with the owner.

Whilst there is a scheduled procurement phase in a project during which the bulk of the purchasing of goods and services takes place, the procurement function should also be involved in the project development process.

In the early feasibility stages of a project, the procurement function should be providing the owner’s project team with information and advice about the marketplace for the key (long lead) equipment critical to the success of the project. Later in the planning and basic design phases, detailed information concerning likely sources of supply, availability, costs, delivery times and foreign currency requirements for the key equipment will be validated. At this stage the information will be expanded to cover other specialized items and bulk materials. The procurement department will also be investigating the capabilities and workloads of potential contractors for the project. They will be developing a recommended tender list for all goods and services, and recommending appropriate contract strategies for discussion with the project manager and other members of the project team. The appropriate specialists in the department will be investigating transport routes, restrictions and constraints, methods of transport, permits and formalities required, customs clearance procedures, duties and so on. They will be checking loading and discharge capabilities as well as handling facilities at ports and transhipment locations.

Once a client has awarded a contract to a contractor to execute the project, the project procurement manager assigned to the project team prepares procedures based on the contractor’s corporate procedures. The procedures will be tailored to suit the client’s requirements, the specifics of the project and project management’s strategy and objectives.

The project procurement manager is responsible for the issue of a multitude of status reports and will be involved in reviewing them, on a regular basis, with the project manager. During the execution phases of a project the project procurement function generates more paperwork than any other department. The following are the main generators of this paperwork:

• the buyer’s report;

• the material status reports;

• vendor data and drawings.

The buyer’s report lists each group of materials or equipment for which enquiries will be issued, listing the names of all the companies who have been invited to tender. The enquiry issue date and the tender due date are shown and, as each tender is received, the date and time of receipt is noted. When the order is eventually placed, the successful vendor is indicated in the report.

The material status report is a much more detailed report which lists each purchase order once it has been placed. The report then includes a complete history of the order until it is actually delivered. Input for the report comes from expeditors (desk-based and field-based), inspectors and shipping specialists. The report will show the required delivery date and the forecast delivery date.

It is the design department that generates the requests for the vast majority of vendor information and this documentation is often controlled by a separate group.

Procurement status reports or materials management systems are crucial to the project manager’s ability to control a project. The systems must be sufficiently flexible to allow one to select different fields of data to produce different reports, for example, by supplier, commodity, material or equipment identification number, work area, drawing number or by promised delivery date. It seems that every company has its own favourite names and formats for each set of reports.

Objectives

Many articles summarize the objectives of procurement as obtaining:

• the right goods and services;

• in the right quantities;

• to the right quality;

• at the right time;

• to the right destination;

• at the right price;

• from the right supplier.

These objectives have the same conflict as the classical Cost–Time–Quality triangle for the project as a whole, and are naturally influenced by the cost, time and quality objectives of the project.

The buying of materials and equipment for a project involving the design and construction of a plant, facility or system is different to the buying of materials for a project involving the manufacture of equipment. In manufacturing, purchasing is more volume-based for repetitive materials. Further, the cost of materials bought from suppliers can make the difference between selling the item and making a profit, or failure to make a sale.

Listen to AT&T’s executive vice president for telephone products:

‘Purchasing is by far the largest single function at AT&T. Nothing we do is more important.

Simple fact: when the goal is boosting profits by dramatically lowering costs, a business should look first to what it buys. On average, manufacturers shell out 55 cents of each dollar of revenues on goods and services, from raw materials to overnight mail. By contrast, labor seldom exceeds 6% of sales, overhead 3%. So purchasing exerts far greater leverage on earnings than anything else. By shrinking the bill 5%, a typical manufacture adds almost 3% to net profits.’1

In process plant projects, for example, purchases are more of a one-off event customized to suit the owner’s or contractor’s specifications. Projects have always striven to buy the right materials, once, at the right time (Just in Time - JIT), in the right quantities, to the right destination. The issues of quality and price can be influenced by who is purchasing the materials – the owner or a contractor. If a contractor is purchasing the materials then they can be influenced by the type of contract that they have with their client. There can be other conflicts in objectives. The owner may have received approval for their project on the basis of the amount of work that the project will generate in the local area. Consequently, they will be seeking to maximize the amount of work done on site. A contractor, on the other hand, will almost always be seeking to minimize the work on site.

Approximately 40 per cent of the total cost of a major engineering and construction project is spent on the procurement of materials and equipment – for a civil engineering project the materials can be as high as 65 per cent. It is, therefore, an extremely important area where it is possible to make significant savings in cost and schedule. Consequently, purchasing objectives can be cost reduction objectives or profit-making objectives. However, in addition to these, there are wider objectives of controlling financial commitments, controlling negotiations and providing information to management.

The design department is responsible for specifying the goods correctly, but, in making the choice of the right materials, different criteria and the needs of different functions should be considered.

Specifying a material that is only marginally better than another, for the service conditions, may require longer delivery and upset the sequence of planned installations operations. Nevertheless, purchasing may not revise any technical requirement.

Purchasing can cause a similar result by selecting a vendor’s price that is lower, but for which a longer delivery period is required, On the other hand, the installation group may try to finish a job sooner in order to save on overhead type costs, without considering the extra costs that will be required for overtime in the design office, or for the premium freight costs needed to expedite deliveries. Savings in one area are only meaningful if larger expenditures are not required in others.

The right quantity for equipment is easy and straightforward, but the right quantities for bulk materials is something that few, if any, organizations can get right – despite the use of computer-aided design. Prefabricating or modularizing, in multi-locations, compounds the problem of getting the location and quantities correct.

The placement of purchase orders in the right order and at the right time is crucial to the progress of a project overall. It is not uncommon for buyers under pressure to make progress in purchasing activities by placing the easy orders first leaving the difficult, but critical, ones until later. The placement of purchase orders releases a number of crucial actions. The first is the reservation of manufacturing capacity. This, in turn, starts the delivery process for the fabrication, construction or installation phase. However, before delivery there is a requirement to provide information and drawings for progressing the design or engineering of the facility concerned.

Sourcing from the right supplier may be the most important objective. Choosing a reliable supplier whose quality and delivery performance can be relied upon will save time, effort an...