Robert H. Bishop

M. K. Ramasubramanian

1.1 Basic Definitions

The definition of mechatronics has evolved since the original definition by the Yasakawa Electric Company. In trademark application documents, Yasakawa defined mechatronics in this way [1,2]:

The word, mechatronics, is composed of “mecha” from mechanism and the “tronics” from electronics. In other words, technologies and developed products will be incorporating electronics more and more into mechanisms, intimately and organically, and making it impossible to tell where one ends and the other begins.

The definition of mechatronics continued to evolve after Yasakawa suggested the original definition. One oft quoted definition of mechatronics was presented by Harashima, Tomizuka, and Fukada in 1996 [3]. In their words, mechatronics is defined as

the synergistic integration of mechanical engineering, with electronics and intelligent computer control in the design and manufacturing of industrial products and processes.

That same year, another definition was suggested by Auslander and Kempf [4]:

Mechatronics is the application of complex decision making to the operation of physical systems.

Yet another definition due to Shetty and Kolk appeared in 1997 [5]:

Mechatronics is a methodology used for the optimal design of electromechanical products.

More recently, we find the suggestion by W. Bolton [6]:

A mechatronic system is not just a marriage of electrical and mechanical systems and is more than just a control system; it is a complete integration of all of them.

All of these definitions and statements about mechatronics are accurate and informative, yet each one in and of itself fails to capture the totality of mechatronics. Despite continuing efforts to define mechatronics, to classify mechatronic products, and to develop a standard mechatronics curriculum, a consensus opinion on an all-encompassing description of “what is mechatronics” eludes us. This lack of consensus is a healthy sign. It says that the field is alive, that it is a youthful subject. Even without an unarguably definitive description of mechatronics, engineers understand from the definitions given above and from their own personal experiences the essence of the philosophy of mechatronics.

For many practicing engineers on the front line of engineering design, mechatronics is nothing new. Many engineering products of the last 25 years integrated mechanical, electrical, and computer systems, yet were designed by engineers that were never formally trained in mechatronics per se. It appears that modern concurrent engineering design practices, now formally viewed as part of the mechatronics specialty, are natural design processes. What is evident is that the study of mechatronics provides a mechanism for scholars interested in understanding and explaining the engineering design process to define, classify, organize, and integrate many aspects of product design into a coherent package. As the historical divisions between mechanical, electrical, aerospace, chemical, civil, and computer engineering become less clearly defined, we should take comfort in the existence of mechatronics as a field of study in academia. The mechatronics specialty provides an educational path, that is, a roadmap, for engineering students studying within the traditional structure of most engineering colleges. Mechatronics is generally recognized worldwide as a vibrant area of study. Undergraduate and graduate programs in mechatronic engineering are now offered in many universities. Refereed journals are being published and dedicated conferences are being organized and are generally highly attended.

It should be understood that mechatronics is not just a convenient structure for investigative studies by academicians; it is a way of life in modern engineering practice. The introduction of the microprocessor in the early 1980s and the ever increasing desired performance to cost ratio revolutionized the paradigm of engineering design. The number of new products being developed at the intersection of traditional disciplines of engineering, computer science, and the natural sciences is ever increasing. New developments in these traditional disciplines are being absorbed into mechatronics design at an ever increasing pace. The ongoing information technology revolution, advances in wireless communication, smart sensors design (enabled by MEMS technology), and embedded systems engineering ensures that the engineering design paradigm will continue to evolve in the early twenty-first century.

1.3 Historical Perspective

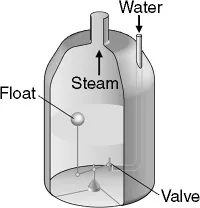

Attempts to construct automated mechanical systems has an interesting history. Actually, the term “automation” was not popularized until the 1940s when it was coined by the Ford Motor Company to denote a process in which a machine transferred a sub-assembly item from one station to another and then positioned the item precisely for additional assembly operations. But successful development of automated mechanical systems occurred long before then. For example, early applications of automatic control systems appeared in Greece from 300 to 1 B.C. with the development of float regulator mechanisms [7]. Two important examples include the water clock of Ktesibios that used a float regulator, and an oil lamp devised by Philon, which also used a float regulator to maintain a constant level of fuel oil. Later, in the first century, Heron of Alexandria published a book entitled Pneumatica that described different types of water-level mechanisms using float regulators.

In Europe and Russia, between seventeenth and nineteenth centuries, many important devices were invented that would eventually contribute to mechatronics. Cornelis Drebbel (1572-1633) of Holland devised the temperature regulator representing one of the first feedback systems of that era. Subsequently, Dennis Papin (1647-1712) invented a pressure safety regulator for steam boilers in 1681. Papin’s pressure regulator is similar to a modern-day pressure-cooker valve. The first mechanical calculating machine was invented by Pascal in 1642 [8]. The first historical feedback system claimed by Russia was developed by Polzunov in 1765 [9]. Polzunov’s water-level float regulator, illustrated in Figure 1.2, employs a float that rises and lowers in relation to the water level, thereby controlling the valve that covers the water inlet in the boiler.

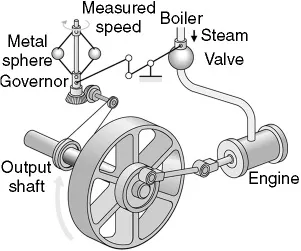

Further evolution in automation was enabled by advancements in control theory traced back to the Watt flyball governor of 1769. The flyball governor, illustrated in Figure 1.3, was used to control the speed of a steam engine [10]. Employing a measurement of the speed of the output shaft and utilizing the motion of the flyball to control the valve, the amount of steam entering the engine is controlled. As the speed of the engine increases, the metal spheres on the governor apparatus rise and extend away from the shaft axis, thereby closing the valve. This is an example of a feedback control system where the feedback signal and the control actuation are completely coupled in the mechanical hardware.

These early successful automation developments were achieved through intuition, application of practical skills, and persistence. The next step in the evolution of automation required a theory of automatic control. The precursor to the numerically controlled (NC) machines for automated manufacturing (to be developed in the 1950s and 60s at MIT) appeared in the early 1800s with the invention of feed-forward control of weaving looms by Joseph Jacquard of France. In the late 1800s, the subject now known as control theory was initiated by J. C. Maxwell through analysis of the set of differential equations describing the flyball governor [11]. Maxwell investigated the effect various system parameters had on the system performance. At about the same time, Vyshnegradskii formulated a mathematical theory of regulators [12]. In the 1830s, Michael Faraday described the law of induction that would form the basis of the electric motor and the electric dynamo. Subsequently, in the late 1880s, Nikola Tesla invented the alternating-current induction motor. The basic idea of controlling a mechanical system automatically was firmly established by the end of 1800s. The evolution of automation would accelerate significantly in the twentieth century.

The development of pneumatic control elements in the 1930s matured to a point of finding applications in the process industries. However, prior to 1940, the design of control systems remained an art generally characterized by trial-and-error methods. During the 1940s, continued advances in mathematical and analytical methods solidified the notion of control engineering as an independent engineering discipline. In the United States, the development of the telephone system and electronic feedback amplifiers spurred the use of feedback by Bode, Nyquist, and Black at Bell Telephone Laboratories [13-17]. The operation of the feedback amplifiers was described in the frequency domain and the ensuing design and analysis practices are now generally classified as “classical control.” During the same time period, control theory was also developing in Russia and eastern Europe. Mathematicians and applied mechanicians in the former Soviet Union dominated the field of controls and concentrated on time domain formulations and differential equation models of systems. Further developments of time domain formulations using state variable system representations occurred in the 1960s and led to design and analysis practices now generally classified as “modern control.”

The World War II war effort led to further advances in the theory and practice of automatic control in an effort to design and construct automatic airplane pilots, gun-positioning systems, radar antenna control systems, and other military systems. The complexity and expected performance of these military systems necessitated an extension of the available control techniques and fostered interest in control systems and the development of new insights and methods. Frequency domain techniques continued to dominate the field of controls following World War II, with the increased use of the Laplace transform, and the use of the so-called s-plane methods, such as designing control systems using root locus.

On the commercial side, driven by cost savings achieved through mass production, automation of the production process was a high priority beginning in the 1940s. During the 1950s, the invention of the cam, linkages, and chain drives became the major enabling technologies for the invention of new products and high-speed precision manufacturing and assembly. Examples include textile and printing machines, paper converting machinery, and sewing machines. High-volume precision manufacturing became a reality during this period. The automated paperboard container-manufacturing machine employs a sheet-fed process wherein the paperboard is cut into a fan shape to form the tapered sidewall, and wrapped around a mandrel. The seam is then heat sealed and held until cured. Another sheet-fed source of paperboard is used to cut out the plate to form the bottom of the paperboard container, formed into a shallow dish through scoring and creasing operations in a die, and assembled to the cup shell. The lower edge of the cup shell is bent inwards over the edge of the bottom plate sid...