Assessing the Environmental Impact of Textiles and the Clothing Supply Chain

- 212 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Assessing the Environmental Impact of Textiles and the Clothing Supply Chain

About This Book

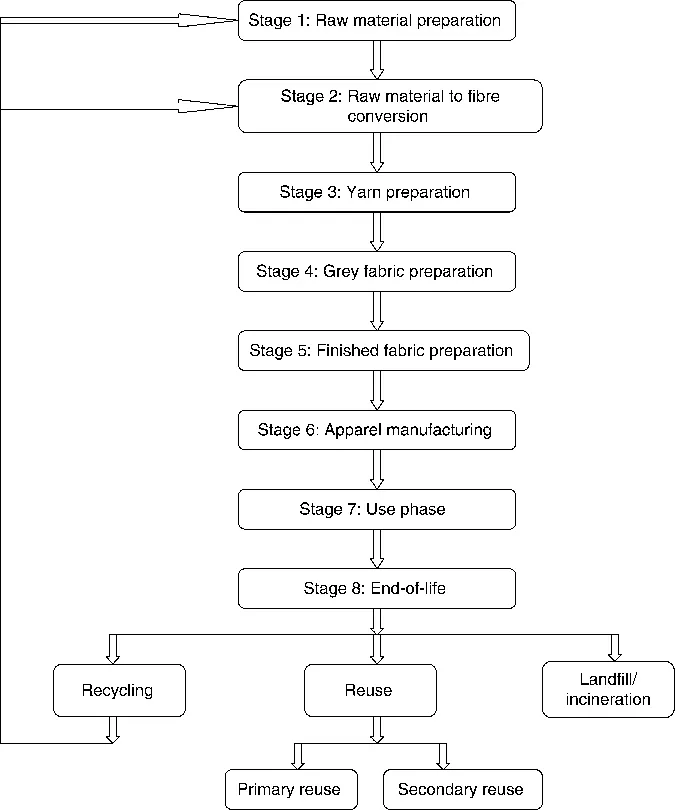

The textile industry impacts the environment in a number of ways, including its use of resources, its impact on global warming, and the amount of pollution and waste it generates. Assessing the Environmental Impact of Textiles and the Clothing Supply Chain reviews methods used to calculate this environmental impact, including product carbon footprints (PCFs), ecological footprints (EFs), and life cycle assessment (LCA).

The first chapters provide an introduction to the textile supply chain and its environmental impact, and an overview of the methods used to measure this impact. The book goes on to consider different environmental impacts of the industry, including greenhouse gas emissions, the water and energy footprints of the industry, and depletion of resources, as well as the use of LCA to assess the overall environmental impact of the textile industry. It then deals with the practice of measuring these impacts before forming a conclusion about the environmental impact of the industry.

Assessing the Environmental Impact of Textiles and the Clothing Supply Chain provides a standard reference for R&D managers in the textile industry and academic researchers in textile science.

- Reviews the main methods used to calculate the textile industry's use of resources, its impact on global warming and the pollution and waste it generates

- Reviews the key methods, their principles and how they can be applied in practice to measure and reduce the environmental impact of textile products

- Includes the following calculation methods: product carbon footprints (PCFs), ecological footprints (EFs) and life cycle assessment (LCA)

Frequently asked questions

Information

The textile supply chain and its environmental impact

Abstract:

1.1 Introduction

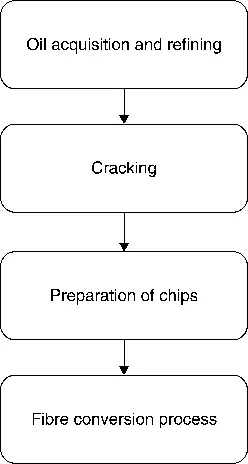

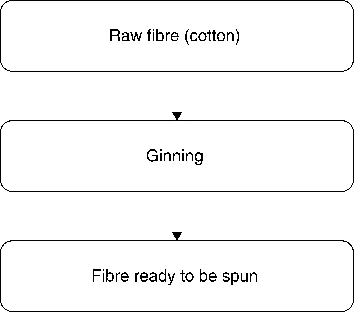

1.2 The textile supply chain: an overview