eBook - ePub

Programmable Controllers for Factory Automation

David Johnson

This is a test

Share book

- 280 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Programmable Controllers for Factory Automation

David Johnson

Book details

Book preview

Table of contents

Citations

About This Book

This book is intended to address both the quantitative and qualitative issues of programmable controllers for factory automation. It is helpful for both the newcomer to the field and the experienced control engineer requiring a fresh perspective.

Frequently asked questions

How do I cancel my subscription?

Can/how do I download books?

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

What is the difference between the pricing plans?

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

What is Perlego?

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Do you support text-to-speech?

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Is Programmable Controllers for Factory Automation an online PDF/ePUB?

Yes, you can access Programmable Controllers for Factory Automation by David Johnson in PDF and/or ePUB format, as well as other popular books in Business & Operations. We have over one million books available in our catalogue for you to explore.

1

Introduction of Programmable Controllers

From a simple heritage, these remarkable systems have evolved to not only replace electromechanical devices, but to solve an ever-increasing array of control problems in both process and nonprocess industries. By all indications, these microprocessor powered giants will continue to break new ground in the automated factory into the 1990s.

1.1 HISTORY

In the 1960s, electromechanical devices were the order of the day as far as control was concerned. These devices, commonly known as relays, were being used by the thousands to control many sequential-type manufacturing processes and stand-alone machines. Many of these relays were in use in the transportation industry, more specifically, the automotive industry. These relays, installed in panels and control cabinets (see Figure 1.1), used hundreds of wires and their interconnections to effect a control solution. The performance of a relay was basically reliable – at least as a single device. But the common applications for relay panels called for 300 to 500 or more relays, and the reliability and maintenance issues associated with supporting these panels became a very great challenge. Cost became another issue, for in spite of the low cost of the relay itself, the installed cost of the panel could be quite high. The total cost including purchased parts, wiring, and installation labor, could range from $30 to $50 per relay. To make matters worse, the constantly changing needs of a process called for recurring modifications of a control panel. With relays, this was a costly prospect, as it was accomplished by a major rewiring effort on the panel. In addition, these changes were sometimes poorly documented, causing a second-shift maintenance nightmare months later. In light of this, it was not uncommon to discard an entire control panel in favor of a new one with the appropriate components wired in a manner suited for the new process. Add to this the unpredictable, and potentially high, cost of maintaining these systems as on high-volume motor vehicle production lines, and it became clear that something was needed to improve the control process – to make it more reliable, easier to troubleshoot, and more adaptable to changing control needs.

Figure 1.1 Photo relay panel installed in cabinet. (Courtesy of General Electric.)

That something, in the late 1960s, was the first programmable controller. This first ‘evolutionary’ system was developed as a specific response to the needs of the major automotive manufacturers in the United States. These early controllers, or programmable logic controllers (PLC), represented the first systems that (1) could be used on the factory floor, (2) could have their ‘logic’ changed without extensive rewiring or component changes, and (3) were easy to diagnose and repair when problems occurred.

It is interesting to observe the progress that has been made in the past 15 years in the programmable controller area. The pioneer products of the late 1960s must have been confusing and frightening to a great number of people. For example, what happened to the hardwired and electromechanical devices that maintenance personnel were used to repairing with hand tools? They were replaced with ‘computers’ disguised as electronics designed to replace relays. Even the programming tools were designed to appear as relay equivalent presentations. We have the opportunity now to examine the promise, in retrospect, that the programmable controller brought to manufacturing.

1.2 BASIC CONCEPTS

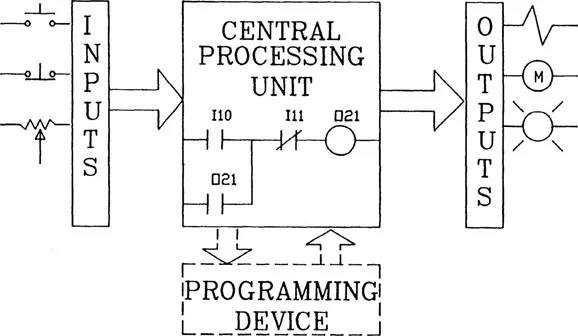

All programmable controllers consist of the basic functional blocks shown in Figure 1.2. We’ll examine each block to understand the relationship to the control system. First we look at the CPU, as it is the heart (or at least the brain) of the system. It consists of a microprocessor, logic memory for the storage of the actual control logic, storage or variable memory for use with data that will ordinarily change as a function of the control program execution, and a power supply to provide electrical power for the processor and memory. Next comes the I/O block. This function takes the control level signals from the CPU and converts them to voltage and current levels suitable for connection with factory grade sensors and actuators. The I/O type can range from digital (discrete or on/off), analog (continuously variable), or a variety of special purpose ‘smart’ I/O which are dedicated to a certain application task. The programmer is shown here, but it is normally used only to initially configure and program a system and is not required for the system to operate. It is also used in troubleshooting a system, and can prove to be a valuable tool in pinpointing the exact cause of a problem. The field devices shown here represent the various sensors and actuators connected to the I/O. These are the arms, legs, eyes, and ears of the system, including pushbuttons, limit switches, proximity switches, photosensors, thermocouples, RTDs, position sensing devices, and bar code readers as input; and pilot lights, display devices, motor starters, DC and AC drives, solenoids, and printers as outputs. Chapters 4 to 10 examine in detail the functions and contributions of the CPU, I/O and programming/documentation systems.

Figure 1.2 Diagram of basic programmable controller functions blocks.

No single attempt could cover its rapidly changing scope, but three basic characteristics can be examined to help classify an industrial control device as a programmable controller.

- Its basic internal operation is to solve logic from the beginning of memory to some specified stopping point, such as end of memory or end of program. Once the end is reached, the operation begins again at the beginning of memory. This scanning process continues from the time power is supplied to the time it is removed.

- The programming logic is a form of a relay ladder diagram, Normally open, normally closed contacts, and relay coils are used within a format utilizing a left and a right vertical rail. Power flow (symbolic positive electron flow) is used to determine which coils or outputs are energized or deenergized.

- The machine is designed for the industrial environment from its basic concept; this protection is not added at a later date. The industrial environment includes unreliable AC power, high temperatures (0 to 60°C), extremes of humidity, vibrations, RF noise, and other similar parameters.

1.3 GENERAL APPLICATION AREAS

The programmable controller is used in a wide variety of control applications today, many of which were not economically possible just a few years ago. This is true for two general reasons: (1) their cost effectiveness (that is, the cost per I/O point) has improved dramatically with the falling prices of microprocessors and related components, and (2) the ability of the controller to solve complex computation and communication tasks has made it possible to use it where a dedicated computer was previously used.

Applications for programmable controllers can be categorized in a number of different ways, including general and industrial application categories. We will see more applications in a later chapter, but it is important to understand the framework in which controllers are presently understood and used so that the full scope of present and future evolution can be examined. It is through the power of applications that controllers can be seen in their full light. Industrial applications include many in both discrete manufacturing and process industries. Automotive industry applications, the genesis of the programmable controller, continue to provide the largest base of opportunity. Other industries, such as food processing and utilities, provide current development opportunities.

There are five general application areas in which programmable controllers are used. A typical installation will use one or more of these integrated to form a complete solution to the control system problem. The five general areas are explained briefly below.

Sequence Control. This is the largest and most common application for programmable controllers today, and is the closest to traditional relay control in its ‘sequential’ nature. Because of the very general nature of this category, it is sometimes difficult to understand the breadth of power that it brings to so many applications. From an applications standpoint, sequence control is found on individual machines or machine lines, on conveyor and packaging machinery, and even on modern elevator control systems.

Motion Control. This is the integration of linear or rotary motion control in the programmable controller. This could be a single or multiple axis drive system control, and can be used with servo, stepper, or hydraulic drives. In early systems, a stand-alone servo drive would be connected to the programmable controller with a series of individual conductors to discrete inputs and outputs. Newer systems integrate this functionality directly into the I/O racks through the use of special I/O boards dedicated to motion control. This eliminates the need to interface the two devices together with discrete I/O. Programmable controller motion control applications include an unending variety of machinery; metal cutting (grinders), metal forming (press brake), assembly machines, and multiple axes of motion can be coordinated for both discrete part and process industry applications. Examples of these would include cartesian robots, and many web related processes that is, film, rubber, and nonwoven textile systems.

Process Control. This is the ability of the programmable controller to control a number of physical parameters such as temperature, pressure, velocity, and flow. This involves the use of analog (continuously variable) I/O to achieve a closed-loop control system. The use of Proportional-Integral-Derivative, (PID) software allows the programmable controller to replace the function of stand-alone loop controllers. Another alternative, described later, is to integrate the loop controllers with the programmable controller, retaining the best features of each. Typical examples of applications include plastic injection molding machines, extrusion process machines, heat treat furnaces, and many other batch-type control applications.

Data Management. The ability to collect, analyze, and manipulate data has only become possible with programmable controllers in the last few years. With the advanced instruction sets and expanded variable memory capacities of the newer programmable controllers, it is now possible for the system to act as a data concentrator, collecting data about the machine or process it is controlling. This data can then be compared to reference data in the controllers memory, or can be sent via a communication function to another intelligent device for analysis or report generation. Any comments that are made about the importance and growing use of data management are probably understatements considering the leap-frog technical solution capabilities it brings to a wide range of applications. Data management is frequently found on large materials handling systems, in unmanned flexible manufacturing cells, and in many process industry applications, that is, paper, primary metals, and food processing.

Communications. This is the ability for the programmable controller to have a ‘window’ to other programmable controllers and intelligent devices. One of the most active development areas in today’s industrial control arena and much Local Area Network (LAN) activity is currently driven by the MAP communications standard. The Manufacturing Automation Protocol (MAP), an activity initiated by General Motors, is intended to connect multi-vendor intelligent devices, including programmable controllers, into a coherent, efficient control network. In addition, higher performance control-oriented networks, sometimes referred to as subnets, offer the ability to tie tog...