The use of bricks and the ancient craft of bricklaying have been in existence for thousands of years. The oldest shaped mud bricks, discovered near Damascus in Syria, date from as far back as 7500BC. Mud bricks were extensively used by the civilization of Ancient Egypt and the first sun-dried clay bricks date back to 4000BC, having been discovered in Mesopotamia (now Iraq). The Chinese also were experts in stonemasonry and bricklaying, the most iconic example of their work being the Great Wall of China, which was begun in the fifth century BC and is claimed to be the only man-made object visible from outer space.

The Romans made use of fired bricks and the Roman legions, who were known to operate mobile kilns, introduced bricks to many parts of their empire, including Europe around 2000 years ago. Great innovators in many areas, the Romans developed bricklaying as a craft, including the use of mortar and different types of bonding arrangements; however, with the eventual decline of the Roman Empire, the craft of bricklaying declined with it.

It was not until the latter half of the seventeenth century, after the Great Fire of London in 1666 in fact, that the English again started to use bricks in building and it took almost another 200 years, until the middle of the nineteenth century, before the mechanized production of bricks began to replace manual methods of manufacture. Despite the advent of mechanized production, however, growth in the brick industry was relatively slow as the moulded clay bricks were still being fired in fairly inefficient static or intermittent kilns. In 1858, a kiln was introduced that allowed all processes associated with firing the bricks to be carried out at the same time, and continuously. Since the introduction of this, the Hoffmann kiln, the brick industry has made great progress, particularly since 1930, when the output of bricks in Great Britain doubled up to the start of the Second World War.

Clay has provided the basic material of construction for centuries and brick properties vary according to the purpose for which they are intended to be used. Today, clay bricks feature in a wide range of buildings and structures, from houses to factories. They are also used in the construction of tunnels, waterways and bridges, and so on. Many hundreds of attractive varieties, colours and texture of brick are available, which can be used imaginatively and creatively to greatly enhance the physical appearance and design of modern buildings.

Concrete is a mixture of cement (usually Ordinary Portland cement), acting as a binder, fine aggregates such as sharp sand, and coarse aggregates such as gravel or crushed stone. Alternatively, fine and coarse aggregates may come pre-mixed as all-in ballast. Water is added to form a paste with the cement, which covers the surface area of every stone and aggregate particle in the mix, binding them together to form a solid mass when the concrete hardens. The aggregates are not physically altered in any way, but are firmly set into the hardened, rock-like cement paste.

Concrete has numerous applications, among them the foundations of buildings, oversite concrete under suspended timber ground floors, solid floor slabs, driveways, paths, benching in man-holes, and many others.

In some cases a chemical plasticizer is mixed with the water in order to make the concrete easier to work and to protect it from frost while it sets.

CEMENT

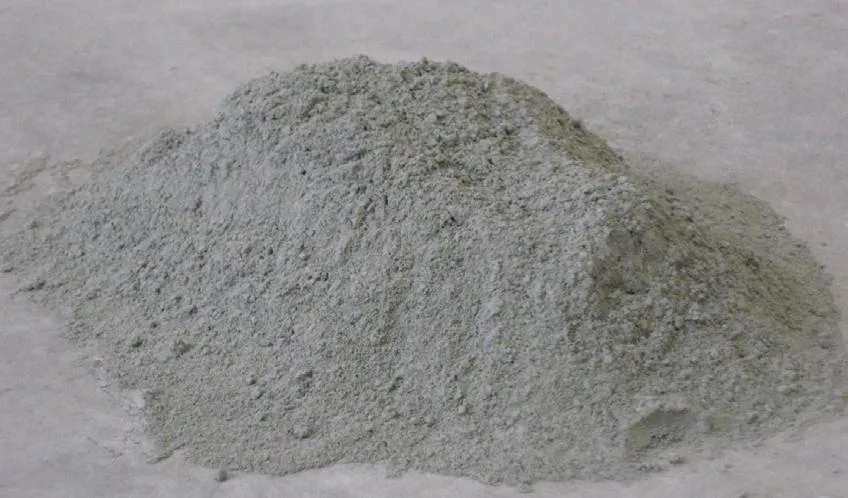

Cement is generally regarded as the most important binding material used in the construction process and is used for the manufacture of mortar and concrete. The use of cement is so common that it is the second most consumed substance in the world after water! The most commonly used is Ordinary Portland cement (OPC), so called because, in its solid state, its grey colour is much like that of natural Portland stone. The fact that Portland cements form a solid when mixed with water means they are often referred to as ‘hydraulic cements’.

Hydration

The reaction between the cement and water is an exothermic (meaning ‘giving off heat’) chemical reaction known as ‘hydration’, which results in the setting of the cement paste. Concrete, and mortars for that matter, set as a result of the completion of the hydration process and not simply by drying out.

Cement Hazards

Cement is classified as an irritant, having the potential to cause severe cases of dermatitis and burning of the skin. Great care must therefore be taken when handling cement (and the materials made from it) in order to avoid contact with the skin or eyes and breathing in cement dust. The use of PPE (personal protective equipment) is essential.

Cement is made from chalk (calcium carbonate) excavated from natural chalk deposits, which is then heated in a rotating cement kiln at temperatures of up to 1450 degrees centigrade. The resultant clinker is then ground to a fine powder, which is then packaged in 25-kg bags.

Although Ordinary Portland cement is the most commonly used for concrete and general construction purposes, there are various other types with slightly altered chemical compositions for specialized circumstances. These include rapid-hardening cement, sulphate-resisting cement, special cements for working in cold weather, and so on.

Being hydraulic, bags of cement must be protected from damp before use. Preferably, bags should be stored clear of the ground on a wooden pallet in a well-ventilated, rain-proof shed. Bags of cement should be stacked flat, no more than five bags high, otherwise the bags at the bottom will set due to the pressure exerted by the bags above. ‘Pressure setting’, as it is called, is sometimes known as ‘warehouse setting’.

Even when stored in ideal conditions, cement still has a ‘shelf life’ and will lose around 20 per cent of its strength over a period of a couple of months. Accordingly, care must be taken to ensure that cement is used in the same sequence in which it was delivered – in other words, old bags fir...