- English

- ePUB (mobile friendly)

- Available on iOS & Android

Sustainable Concrete Solutions

About this book

The challenges facing humanity in the 21st century include climate change, population growth, overconsumption of resources, overproduction of waste and increasing energy demands. For construction practitioners, responding to these challenges means creating a built environment that provides accommodation and infrastructure with better whole-life performance using lower volumes of primary materials, less non-renewable energy, wasting less and causing fewer disturbances to the natural environment. Concrete is ubiquitous in the built environment. It is therefore essential that it is used in the most sustainable way so practitioners must become aware of the range of sustainable concrete solutions available for construction. While sustainable development has been embedded into engineering curricula, it can be difficult for students and academics to be fully aware of the innovations in sustainable construction that are developed by the industry.

Sustainable Concrete Solutions serves as an introduction to and an overview of the latest developments in sustainable concrete construction. It provides useful guidance, with further references, to students, researchers, academics and practitioners of all construction disciplines who are faced with the challenge of designing, specifying and constructing with concrete.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

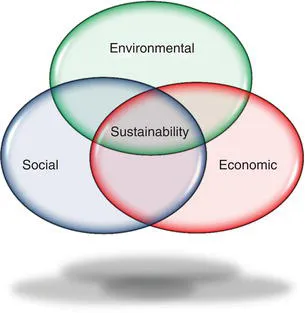

1.1 Sustainability and sustainable development

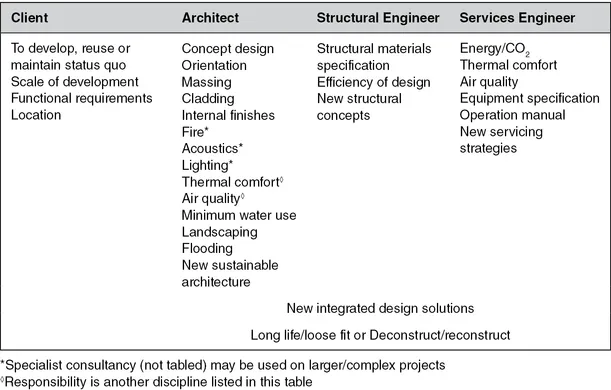

1.2 The role of the design team in sustainable development

1.3 Sustainability credentials of concrete

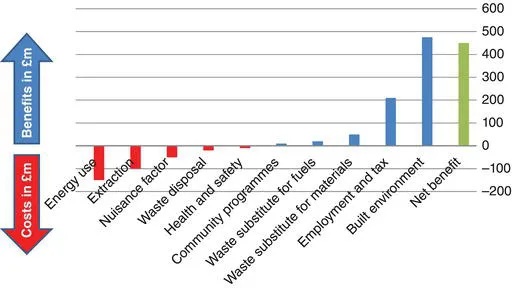

| The sustainability performance benefits of concrete Fire Environmental Concrete does not burn and therefore it reduces noxious emissions from a fire, and wastage of materials. Social The resilience of concrete reduces damage and limits the potential loss of livelihood or homes through a fire. During construction there is no risk to neighbours of the concrete frame being a fire hazard. Economic Regulations require safe evacuation of occupants but not property safety. Concrete structures comply with life safety regulation but can also resist fire to enable cost-effective repair and re-use. Thermal Mass Environmental Concrete’s thermal mass allows it to be used to reduce heating and cooling energy of buildings. Social The thermal mass of concrete can be used to reduce overheating in a building. Occupants affected by public funding and CO2 targets, in social housing and schools, are at risk of overheating if energy use cannot be reduced by no cost options. Economic Using the thermal mass of concrete will lower running costs of a building. It will also reduce the plant needed on site, leading to reduced maintenance costs. Acoustic Performance Environmental Concrete has good acoustic performance and there is less reliance on finishes and materials which have a short lifespan. Hence less material is used and potential waste is avoided. Social Concrete’s mass absorbs sound, ensuring quality of life, particularly in high density living, where dwellings are prone to acoustic break-in. Economic Concrete walls and floors provide required acoustic separation with minimum finishes, hence minimum cost and maintenance. Durability Environmental Due to the long life of all concrete structures, material impacts on the environment are kept to an absolute minimum. Social The durability of concrete structures means that, once built, they are rarely out of use for maintenance and hence have minimum social disruption. Economic Concrete is a very stable and durable material with an extremely long life. As a result, maintenance costs are minimal for concrete structures. Robustness/Security Environmental Concrete structures are robust, reducing risk of damage to finishes, hence less use of materials through the whole life cycle of structures. Social Solid concrete party walls provide safe, secure buildings. Prevention of intruders helps to build safer communities. Concrete infrastructure is robust against vandalism/terrorism minimising social disruption. Economic Concrete structures, particularly if finishes are minimised, will suffer less damage and cost less to repair and maintain. Flood Resilience Environmental The flood resilience of concrete means it retains structural integrity, resulting in minimum wastage of materials following a flood event. Social A concrete structure will resist water penetration, keeping inconvenience and disruption to business, homeowners and the community to a minimum following a flood event. Economic Downtime of businesses, homes and essential community services, is minimised if flooded buildings are constructed in concrete. |

| The Sustainability Credentials of Specified Products: Precast, Ready-mixed and Reinforcement Precast Concrete Products CO2: A commitment to use additional cementitious materials where performance requirements permit exists throughout the industry. Transport distance for the average delivery of precast concrete products is 106 kilometres. Recycling: Recycling systems capture virtually all process water, slurry, aggregates or cement and these are re-used in the production process. Around 96% of the waste produced by the precast sector is recycled or re-used. Resource depletion: Over 21% of aggregates used in the precast sector are recycled or from secondary sources. The sector has set a target to increase the use of additional cementitious materials to 25%. Precast products can often be re-used in their entirety. Waste: The precast concrete sector uses more waste than it produces. A tonne of precast product uses 210kg of secondary materials and by-products and produces only 1.76kg of waste that goes to landfill. Concrete buildings can be designed with less finishes reducing the associated material waste. Water: Dependency on mains water supplies is being drastically reduced across the industry as companies adopt recycling systems and alternative water sources such as rainwater harvesting. Approximately 132 litres of water are used per tonne of precast concrete product; 36% of which is from licensed non-mains sources. Water-reducing admixtures also minimise water use. Emissions: The precast concrete sector is closely regulated by the Environment Agency. In 2012 the sector achieved an increase in the percentage of tonnage covered Environmental Management Schemes (EMS) to over 88%. A target has been set to increase this to 95% by 2020. Biodiversity: Companies with factories in more rural areas are increasingly committed to protecting and enhancing the natural environment. A site in Yorkshire was the first manufacturing site to attain The Wildlife Trust’s ‘Biodiversity Benchmark’. Health and Safety: The comprehensive British Precast health and safety scheme has helped members reduce their overall incidence rates by two thirds compared to 2000. Admixtures are used to produce self-compacting concrete which does not require vibration leading to quieter working environments. Ready-mixed Concrete CO2: Additional cementitious materials and admixtures are used by most concrete manufacturers to optimise cement content and can reduce the embodied CO2 of the concrete. Transportation CO2 is minimal with the average delivery distance of ready-mixed concrete being 12 kilometres and 50% of ready-mixed plants are located at the aggregate extraction site. Recycling: At the end of the life of a structure, all cured concrete waste can be recycled to create new construction materials. Resource depletion: Every tonne of ground granulated blast-furnace slag (GGBS) or fly ash used in concrete mixes saves about 1.4 tonnes of raw materials and fossil fuels. Aggregates are abundant the world over and the UK has enough aggregate reserves to last for hundreds of thousands of years at current rates of usage (McLaren et al., 1999). Waste: Modern formwork systems and efficient site management minimise ready-mixed wastage which is estimated at less than 2% of production output. Systems are available to re-use ‘returned ready-mixed concrete’ and this does not go to landfill. Concrete buildings can be designed with less finishes reducing the associated ma... |

Table of contents

- Cover

- Title page

- Copyright page

- Foreword

- Preface

- 1 Introduction

- 2 Challenges and Responses

- 3 Conceptual Design of Buildings and Infrastructure

- 4 Material Specification

- 5 Construction, Operation and End of Life

- Appendix A: Thermal Mass

- Appendix B: Biomass Substitution

- Appendix C: Choice of Concrete Slab Options

- Appendix D: Example on Embodied CO2 for a Building Slab

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app