![]()

CHAPTER 1

INTRODUCTION

A confident understanding of stitch and seam types, together with a sound knowledge of the basics of assembly, is fundamental to the creation of garments. Armed with this information and understanding you will be able to translate your design ideas into reality, your own three-dimensional design creations.

This book and the illustrative videos cover the essential technology required to get you started in garment assembly by developing your understanding of which stitch and seam type to select for a particular fabric and garment type, as well as the knowledge to construct a range of basic techniques to assemble entire garments using the correct components.

Every stage of constructing garment parts, such as inserting a zip, sewing a dart, assembling and attaching a shirt collar, etc., is covered in the subsequent chapters.

Joining fabric by means of sewing dates back to 28,000 BC, with the earliest known sewing tool: a hand crafted needle made from bone with a split head instead of an eye. The sewing machine was not developed until the 1700s but it did not go into mass production until the 1800s. This machine could produce 250 stitches per minute, which equated to the sewing capacity of five people sewing by hand. Today, modern industrial sewing machines are automated and can exceed speeds of 5000 stitches per minute.

This book covers the techniques and tools used to construct garments for today’s fashion industry using modern industrial equipment as well as an understanding of how to resolve sewing problems, such as seam pucker, etc., should they arise during the sewing process.

GETTING STARTED

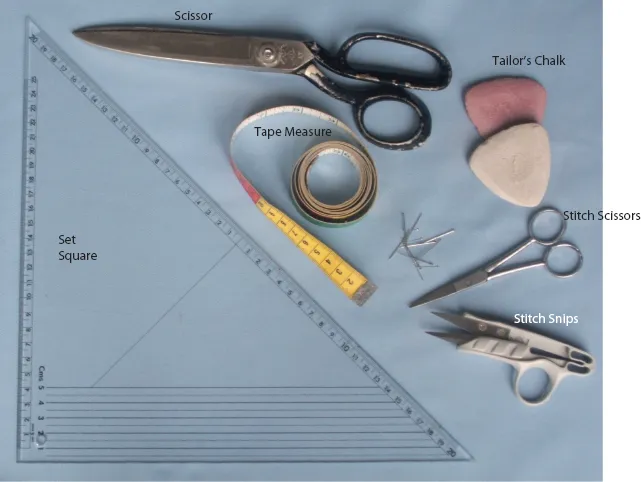

Working with the correct tools is essential: below are some of the key pieces of equipment required:

Fabric scissors/shears for cutting fabrics and trimming such as interlining, elastics, etc.

Quality fabric scissors/shears have tempered steel or stainless steel blades that will create an even cut along the entire length of the blade. The blades are joined by a screw, not a rivet, which means that the scissors can be adjusted or repaired if they are damaged.

Fabric shears generally have blades which are more than 6 inches or 15.24cms in length.

Stitch scissors or snips for cutting threads and trimming surplus fabrics during the sewing process.

The tips of both blades should be pointed to enable you to unpick unwanted stitches. The scissors should be easy to handle but large enough to cut through layers of fabric.

Stitch snips are used for unpicking stitching, trimming threads and trimming surplus fabrics.

Tape measure used to accurately measure seam allowances, body and garment dimensions.

The tape should be non-stretchable but flexible with centimetre markings.

Tailor’s chalk for marking the garment pieces on the fabric and marking locations which are key to the sewing process.

This chalk will not leave a permanent mark on the fabric; it is used to mark the garment pieces or locations such as dart ends, hem lines, etc. on the fabric. When the marks are no longer required, the chalk marks will brush off, leaving no residue behind.

The most common form of tailor’s chalk is a thin triangular shape which can be sharpened and the thin edge is used to mark the fabric. It is also available in the form of a powder with an applicator and in pencil form.

Pins used for temporarily attaching fabric pieces together.

Set square for marking straight lines and cutting strips of fabric for binding.

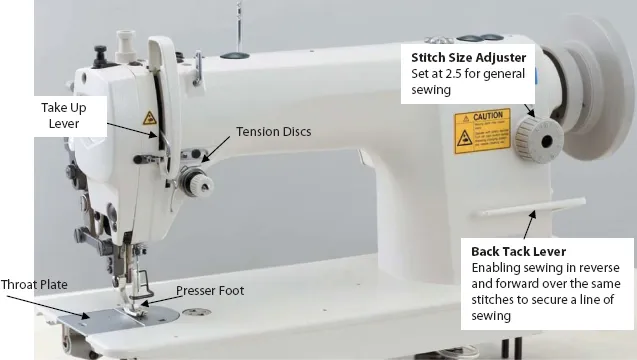

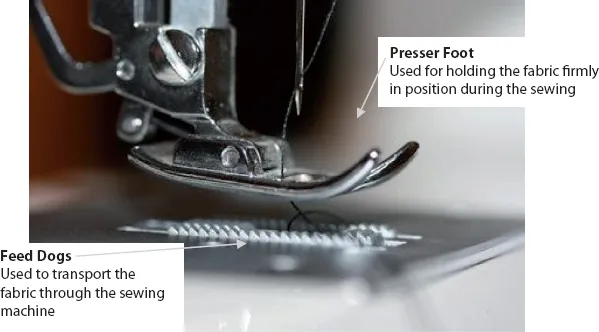

GETTING TO KNOW THE PARTS OF THE SEWING MACHINE

The Fashion Designer’s understanding of the garment assembly process is key to the creative process. The correct selection of stitch and seam types together with the right choice of thread and interlining to stabilise garment parts are fundamental to good garment design and instrumental to success in the creation of garments.

![]()

CHAPTER 2

STITCH & SEAM TYPES

Joining fabric pieces together by sewing produces both strength and flexibility in a seam. Many attempts have been made to develop other processes for joining fabric pieces together, but achieving manufacturing speed and flexibility as well as good seam appearance and performance has proved difficult for many fabric types.

Seams can be joined by a process called welding, as an alternative to sewing. This type of seam joining technology bonds or sticks together fabrics which have a predominant composition of synthetic fibres. The child in the picture is wearing a coat that has been made from lightweight PVC. Welding seams together has limited applications; seams tend to be noticeably stiffer than those that have been joined using traditional stitching methods and seams cannot be welded when the fabric is predominantly made from natural fibres. Generally, welded seams are stronger than conventionally sewn seams because the welding process does not use a needle to create holes in the fabric and weaken the fabric structure. Each section of the welded seam is bonded independently. In conventional seams, if one stitch is broken, the whole seam is compromised, since all the stitches are connected. Many performance waterproof outdoor garments are constructed using a combination of traditional sewing and welding. The seam is sewn with a 5mm seam width, and then has a waterproof tape welded on top, to prevent water from seeping through the holes that have been made in the fabric by the needle. Welding technology is also used for securing decorat...