- English

- ePUB (mobile friendly)

- Available on iOS & Android

Reliability Engineering

About this book

An Integrated Approach to Product Development

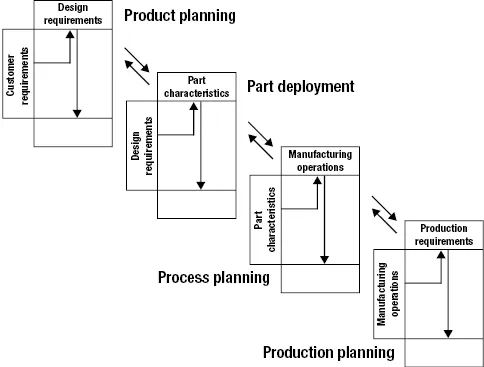

Reliability Engineering presents an integrated approach to the design, engineering, and management of reliability activities throughout the life cycle of a product, including concept, research and development, design, manufacturing, assembly, sales, and service. Containing illustrative guides that include worked problems, numerical examples, homework problems, a solutions manual, and class-tested materials, it demonstrates to product development and manufacturing professionals how to distribute key reliability practices throughout an organization.

The authors explain how to integrate reliability methods and techniques in the Six Sigma process and Design for Six Sigma (DFSS). They also discuss relationships between warranty and reliability, as well as legal and liability issues. Other topics covered include:

- Reliability engineering in the 21 st Century

- Probability life distributions for reliability analysis

- Process control and process capability

- Failure modes, mechanisms, and effects analysis

- Health monitoring and prognostics

- Reliability tests and reliability estimation

Reliability Engineering provides a comprehensive list of references on the topics covered in each chapter. It is an invaluable resource for those interested in gaining fundamental knowledge of the practical aspects of reliability in design, manufacturing, and testing. In addition, it is useful for implementation and management of reliability programs.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Reliability Engineering in the Twenty-First Century

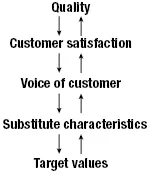

1.1 What Is Quality?

1.2 What Is Reliability?

- Reduction of things gone wrong (Johnson and Nilsson 2003).

- An attribute of a product that describes whether the product does what the user wants it to do, when the user wants it to do so (Condra 2001).

- The capability of a product to meet customer expectations of product performance over time (Stracener 1997).

- The probability that a device, product, or system will not fail for a given period of time under specified operating conditions (Shishko 1995).

1.2.1 The Ability to Perform as Intended

Table of contents

- Cover

- Table of Contents

- Wiley Series in Systems Engineering and Management

- Title page

- Copyright page

- Preface

- 1: Reliability Engineering in the Twenty-First Century

- 2: Reliability Concepts

- 3: Probability and Life Distributions for Reliability Analysis

- 4: Design for Six Sigma

- 5: Product Development

- 6: Product Requirements and Constraints

- 7: Life-Cycle Conditions

- 8: Reliability Capability

- 9: Parts Selection and Management

- 10: Failure Modes, Mechanisms, and Effects Analysis

- 11: Probabilistic Design for Reliability and the Factor of Safety

- 12: Derating and Uprating

- 13: Reliability Estimation Techniques

- 14: Process Control and Process Capability

- 15: Product Screening and Burn-In Strategies

- 16: Analyzing Product Failures and Root Causes

- 17: System Reliability Modeling

- 18: Health Monitoring and Prognostics

- 19: Warranty Analysis

- Appendix A: Some Useful Integrals

- Appendix B: Table for Gamma Function

- Appendix C: Table for Cumulative Standard Normal Distribution

- Appendix D: Values for the Percentage Points tα,ν of the t-Distribution

- Appendix E: Percentage Points X2α,ν of the Chi-Square Distribution

- Appendix F: Percentage Points for the F-Distribution

- Bibliography

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app