![]()

Chapter 1

Taking the Lean Approach

Lean Distribution breaks the forecast accuracy barrier to improving customer service and profit with flawless execution of simplified operating processes

Competition is growing at an ever-increasing rate, and price tends to be the main battleground. Finding the lowest-cost source or manufacturing location has been the strategy with sourcing from China, the preeminent destination. Low cost sourcing is creating and extending supply chains across the globe making distributing products more challenging than ever. There is just no room for error when planning and moving products across complex, global supply chains.

Distribution in these price-sensitive times must evolve to meet the competitive threats and realities of global markets. In the past, distribution processes relied on customer order forecasts to find the most cost-effective plan, but forecast accuracy continues to be an elusive goal. Forecast-based plans are becoming less reliable, making cost reductions more elusive.

Some companies have been successful with new distribution processes and strategies that transcend the forecast accuracy barrier to lower costs. Dell Computer, Wal-Mart, Apple, and others are using advanced approaches combined with Lean principles to drive new levels of competition. The results are evident in any analysis of Dell’s working capital: it is actually negative! With negative working capital, Dell’s profit is increased by the leverage gained from current assets, a very uncommon effect. Can any other significant business boast similar results? Clearly, these companies are taking new approaches that their competitors cannot match.

Apple and Wal-Mart streamlined the global distribution model. Consider how some of the newest products are sourced, sold, and distributed without time moving through distribution centers in the United States. The model is to reduce contact, reduce time to consumer, and completely eliminate as much cost as possible. The ideal situation is direct from source to consumer.

Current operating paradigms, measures, and business processes that seek to forecast, plan, and optimize distribution into perfection stand in the way of the dramatic changes that Dell, Apple, and Wal-Mart are pursuing. Consumers and industrial markets are just moving too fast for forecasts to be sufficiently accurate to optimize and execute a plan. The alternative? A simplicity, flexibility, and market-driven approach built around Lean principles in distribution.

THE LEAN CHANGE IN DISTRIBUTION

Distribution operations are particularly susceptible to globalization trends due to the direct linkage to customer service, the limited value added, and the high levels of cost across distribution. Changes in plans quickly impact customer service and/or costs. Only well-optimized plans that are flawlessly executed meet distribution’s exceedingly stringent standards for both service and low cost. Plan changes challenge distribution optimization and the organization’s ability to meet performance objectives.

The Lean Distribution approach increases flexibility and simplicity and thus reduces the reliance on forecasts and optimized plans to achieve results. With Lean, process and performance improvement is focused on reducing lead time, reducing lot sizes, and increasing reliability, yielding the flexibility and simplicity required to achieve consistent results. Lean Distribution takes a very different approach from an optimization and planning approach that is based on fixed lead times and lot sizes. Forecast-based optimization seeks to reschedule the orders and inventory within the plan in order to reduce costs, whereas Lean seeks to create flexible distribution operations that respond to changing market needs.

THE RFID CHANGE DILEMMA

A customer-driven initiative to streamline supply chains and sourcing that is currently impacting distribution is radio frequency identification (RFID). RFID is the latest initiative by Wal-Mart, the United States Department of Defense (DoD), and others to improve the flow of incoming products. These customer requests to tag pallets or cases with an RFID tag as well as the current bar code appear to add cost and time to each supplier’s distribution process. The benefits are most evident in the customer’s operations (Wal-Mart, etc.), yet these customers are not willing to pay increased prices that account for the tags and additional work suppliers must perform to transmit RFID data. As a result, suppliers are making limited efforts to comply, and distribution is where most of the added costs and time reside.

The majority of professional conversation around RFID tends to relate to technical standards or RFID costs rather than specific distribution transformation capabilities. Like the bar code transition of 30 years ago, the RFID movement will continue to raise cost-related objections until the technology becomes ingrained across nearly all supply chains and is nearly “invisible” to cost measurement. The benefit question remains focused on how the customer gains value and not how suppliers and their customers will transform supply chains and distribution.

This missing link to RFID benefits for suppliers is the fundamental disconnect for distribution processes. The operations paradigm is to reduce the most observable and measurable costs, such as transportation and warehouse labor. RFID technologies provide transformational capabilities, but ones that have not been sufficiently explored. The customers seek continual cost and service improvement, but how the supply chain will be operated differently has not been defined. With Lean Distribution, approaches to leverage RFID signals for replenishment can be identified.

THE FORECAST BARRIER

Customer order forecasts are the starting point for nearly all business, operational, and financial planning. It is very difficult to get around it: forecasts are the best estimates for the market directions, volumes, and pricing necessary to make many decisions across any business. Commitments to suppliers, setting operating levels, and projecting financial results are all driven from the forecast. These many decisions require review, revision, and change as forecasts are updated and revised, an almost daily process to keep pace with the market. So forecasts are absolutely necessary, but also have the unintended consequence of producing continuous disruption as organizations strive to hit plans driven by forecasts that are moving targets.

Forecasts change frequently as customers change plans to adjust to market conditions. So why do companies spend so much time and place so much importance on demand forecasts that change frequently and at times change dramatically? The answer lies in the forecast as the foundation for all business, operational, and financial planning. The forecast initiates and dominates these business processes as the organization diligently works to ensure excellent customer service and low costs by planning from the forecast.

Distribution tends to be a lighting rod for forecasting issues and inaccuracy, because excess or inadequate inventory is highly visible in a distribution center. There are immediate impacts to service in distribution for inventory imbalances, many of which are “blamed” on poor forecasts. So the success of forecasting and the subsequent planning processes can be assessed with distribution service levels, inventories, resources, and costs. The effectiveness of these distribution measures typically is tied back to planning processes and in many ways is limited by the effectiveness of forecasting.

THE BALANCING ACT

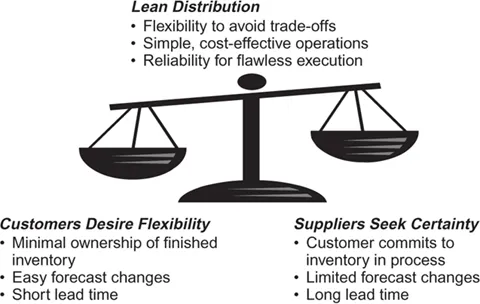

The inevitability of forecast change builds contention into the relationship between supplier and customer. Suppliers desire certainty with fixed purchase schedules, and customers desire flexibility to change with their market. This contention is shown in Figure 1.1 as the difference in interests between customer and supplier. From a customer’s perspective, the flexibility to change on short notice is preferred over firm plans that cannot change as the market or competition changes. However, suppliers seek certainty, long lead times, and limited forecast changes. Clearly, customer and supplier interests may not be fully aligned. The root of their differences can be a supplier’s focus on controlling costs with stable plans and lead time, while the customer may have the “luxury” of making changes to forecasts without concerns that prices will increase.

Depending on their relative negotiating positions and strengths, this balancing act may shift toward one or the other party. Tilting toward the customer tends to focus more on maximizing the total sales through the supply chain with quick responses to market changes, despite concerns over cost implications at the supplier. Conversely, strong suppliers will receive more assurances and control over forecast changes that may impact their costs or profitability. Frequently the struggle is really within the supplier as Marketing seeks to maximize sales while Operations and Finance struggle to maintain profitability. In a “sales”-driven organization, the internal struggle may not be pronounced, because the operators know the changes must be accommodated and they may have some level of inefficiency budgeted to compensate.

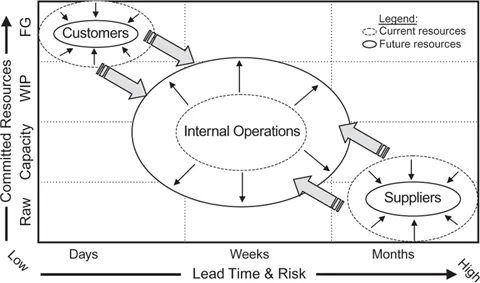

Another view of the flexibility dynamic can be found by assessing the risks and resources across the supply chain. Figure 1.2 has circles representing the amount of inventory, resources, and risk across the supply chain. Customers typically desire to push inventory responsibility back to their suppliers, displayed with arrows toward Internal Operations. On the other side, a supplier’s supplier will likewise seek to receive commitments and push inventory and commitment toward the Internal Operations of their customer. The longer the lead times and higher the inventories are, the more risk across the supply chain. The only question becomes which parties carry the risk.

Mapping the extent of resource commitment for each party can assess the risk inherent in a specific supply chain and across distribution operations. Contract and business relationship negotiations tend to move these commitments around rather than reduce or even eliminate them. The key to successful relationships across the entire supply chain lies in reducing risk and eliminating resource commitments, the fundamental tenets of Lean.

With Lean Distribution, the approach is to clarify how risks can be mitigated, total supply chain costs reduced, and service improved, while increasing focus on maximizing total sales and volume throughput. The Lean approach requires a thorough reevaluation of current processes and practices to break the trade-offs inherent in most forecast-based planning and optimization processes.

BUSINESS AND OPERATIONAL PLANS

Business planning may seem like a “necessary evil” to meet customer orders, reach financial results, and optimize performance. Planning requires detailed customer demand forecasting, which can be time consuming, contentious, second-guessed, and frequently inaccurate. Executives’ time and energy can be sapped by these processes due to the need to synchronize business plans to meet financial objectives. In the end, the business plan may be less a true reflection of the market and more a set of plans and objectives necessary to meet the financial performance required by shareholders and financial markets.

Planning processes are focused on these important objectives because of the pressure executives are under to perform. Due to the difficulty of meeting ever-increasing objectives, the tendency may be to increase the detail of plans to improve execution, ownership, and accountability across the organization.

What may be curious is the inaccuracy of the underlying assumptions for these increasingly detailed and complicated plans. Market forecasts are the starting point and the data with the greatest degree of error and change. Forecasting customer demand may range from highly sophisticated analytics to rudimentary estimates, but ultimately it requires frequent updates. Markets move fast, and organizations devote an extensive amount of time and effort to forecasting and planning in a quest for accuracy.

As forecasts are revised and business plans updated, problems are created in the form of changing schedules across and down through the organization. The revised plans require many reactions to change all of the inputs to business planning: purchase orders, production schedules, transportation plans, and many others. Planning today creates numerous “ripple effects” in nearly all functions of the organization. These ripple effects can be frustrating for the organization as more and more details are created and then changed with every new revision of the forecast.

FORECAST ACCURACY

How accurate are forecasts? Have they ever been sufficiently accurate for the planning, sourcing, operations, distribution, and logistics users? Are there complaints about inaccuracy? This may seem like an odd question, since logic dictates that forecasts are not correct, yet nearly all daily schedules are driven by detailed forecasts and commit large portions of resources based on them. In fact, these plans are the cornerstone for nearly all operational performance and cost reduction efforts despite the fact that forecasts are rarely accurate, except in total sales dollars or an aggregate volume measure.

But accuracy in aggregate units does not support operational planning and cost reduction efforts. ...