Industrial Crystallization Process Monitoring and Control

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Industrial Crystallization Process Monitoring and Control

About This Book

Crystallization is an important technique for separation and purification of substances as well as for product design in chemical, pharmaceutical and biotechnological process industries. This ready reference and handbook draws on research work and industrial practice of a large group of experts in the various areas of industrial crystallization processes, capturing the essence of current trends, the markets, design tools and technologies in this key field. Along the way, it outlines trouble free production, provides laboratory controls, analyses case studies and discusses new challenges. First the instrumentation and techniques used to measure the crystal size distribution, the nucleation and solubility points, and the chemical composition of the solid and liquid phase are outlined. Then the main techniques adopted to control industrial crystallizers, starting from fundamental approaches to the most advanced ones, including the multivariable predictive control are described. An overview of the main crystallizer types is given with details of the main control schemes adopted in industry as well as the more suitable sensors and actuators.

Frequently asked questions

Information

1.1 Introduction

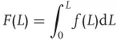

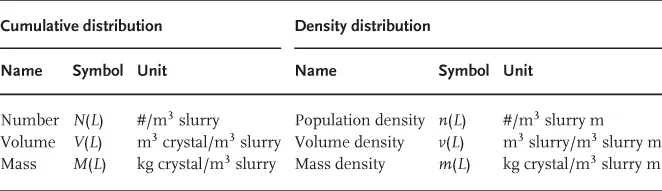

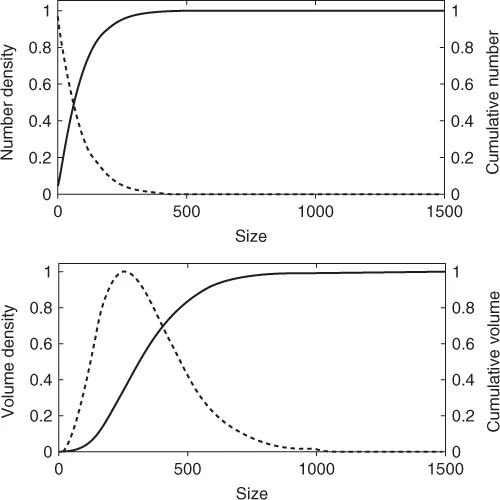

1.2 Particle Size Distribution

Table of contents

- Cover

- Related Titles

- Title Page

- Copyright

- Preface

- Scope of the Book

- List of Contributors

- Chapter 1: Characterization of Crystal Size Distribution

- Chapter 2: Forward Light Scattering

- Chapter 3: Focused Beam Reflectance Measurement

- Chapter 4: Turbidimetry for the Estimation of Crystal Average Size

- Chapter 5: Imaging

- Chapter 6: Turbidimetry and Nephelometry

- Chapter 7: Speed of Sound

- Chapter 8: In-Line Process Refractometer for Concentration Measurement in Sugar Crystallizers

- Chapter 9: ATR-FTIR Spectroscopy

- Chapter 10: Raman Spectroscopy

- Chapter 11: Basic Recipe Control

- Chapter 12: Seeding Technique in Batch Crystallization

- Chapter 13: Advanced Recipe Control

- Chapter 14: Advanced Model-Based Recipe Control

- Chapter 15: Fines Removal

- Chapter 16: Model Predictive Control

- Chapter 17: Industrial Crystallizers Design and Control

- Index