![]()

PartI

Problems Regarding Organic Materials and Sustainable Development

![]()

Chapter 1

Organic Materials used in Construction at the Dawn of the Third Millennium 1

To the general public the most well-known available construction materials are stone, terra cotta (tiles and bricks), concrete, iron (or steel) and, with a little insistence, timber, or even tar or bitumen1, for those thinking of road construction. The reality faced by builders on a daily basis is more complex; organic materials hold a strategically very important position, particularly in the technical uses of concrete and steel.

What exactly are organic materials?

First of all, these are materials whose physical-chemical structure falls within the category of organic chemistry, meaning that they are essentially made up of carbon and hydrogen. Putting timber aside, (and also bitumen, to a certain extent), here we are most often concerned with synthetic products manufactured using natural products: coal, oil, rocks, air, sea water, etc Their usage domains are very diverse, but can be categorized into three main roles which relate to cohesion, structure protection and achievement of structural, packing or design elements.

The first role relates to cohesion auxiliaries. Whether we are dealing with bitumen for road construction, binding agents of paint, polymers used in the formulation of repair or adhesive bonding products, or admixtures used to facilitate laying concrete, in all these examples we are looking to bind together units of granular minerals on different scales. Therefore, we can no longer talk about high performance concrete without mentioning the use of organic materials, either as a binding agent (asphalt concrete), or as an admixture (hydraulic concrete).

The second role concerns the protection of structures, firstly with respect to water (this is the general problem for waterproofing or caulking), then in relation to all kinds of pollutants, meaning the creation of a barrier effect, in the general sense.

The third role, achievement of various elements, concerns firstly the different uses of timber, which ranges from a building’s structure to its trimmings. It also deals with a series of “plastic” applications, which range from the envelope, to interior house fittings.

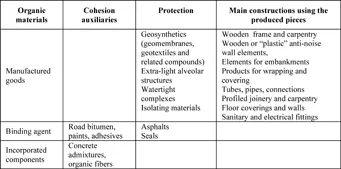

Now if we take an interest in their use and function, we can then distinguish three uses:

– as they are, i.e. in the form of manufactured goods;

– as binders, i.e. used with granular components;

– as being incorporated into a cement mixture to modify its properties; they can then be considered as materials of the third degree, in relation to the first two.

This can all be presented in Table 1.1.

These classifications give us a basic overview of these materials, but they do not provide anything about their properties. In particular, they do not tell us about their potential health and environmental impacts. It is essential to take an interest in their physico-chemical nature. Thus four categories can be distinguished:

– polymer-based products specifically;

– bitumens and related products;

– organic matrix composite materials;

– timber.

There are two ways to consider specifically organic polymers according to whether they are the base of manufactured goods – where they operate “finished”, as “plastics”, rubbers and geosynthetiques – or they form on site, such as the resins used for adhesive bonding or repair of concrete structures, high performances paints, protection coatings, etc. – and are called “formulated”. Finally we should not forget the “incorporated”, the last generation of rheological admixtures whose active product is a polymer used for steric or electrostatic effects.

The composites used in construction also manifest these two different ways: elaborate products – panels, beams, connector pieces, etc. – or systems reacting at the moment when repairs are carried out on structures, or large buildings, antiseismic structures, etc.

1.1. Specifically polymer-based products

1.1.1. Plastics, rubbers and geosynthetics

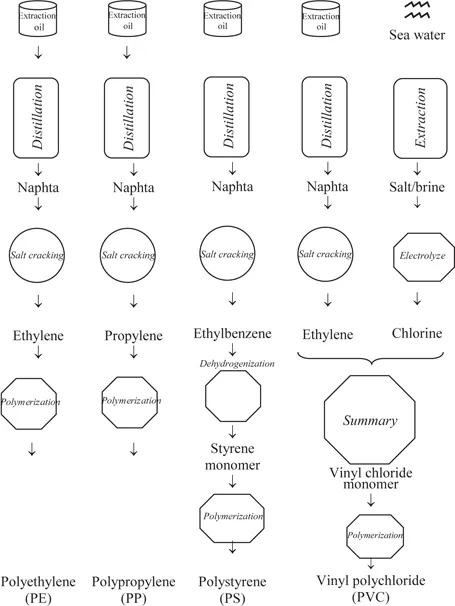

Oil is the main origin of organic polymers. Figure 1.1 presents the diagram for the manufacturing of four main polymers used in the field of construction. It shows that two operators intervene successively: initially the refiner which insulates the basic commodities (monomelic or precursors of the monomers) and then the chemist, who prepares the monomers, formulates and manufactures the desired polymer (polymerization). In this diagram the paths are simple but it has already been seen, with PVC, that things can become complicated: here the chemist must synthesize the monomer (the vinyl chloride) starting with the precursor provided by the refiner (ethylene) and chlorine, itself taken from sodium chloride (marine salt or extract of mines). Here, we are still using simple processes, which it will be possible to follow during the material's lifecycle analysis.

Table 1.2. The presence of “plastics” in the construction industry

| Chemical families | Polymers concerned | Applications |

| Polyolefins (ormacromolecularparaffins) | high-density polyethylene (HDP)

Low density polyethylene (LDH)

Polypropylene (PP) | Geomembranes, gas pipelines, hot and coldwater pipelines under pressure (transportand distribution)

Guy and pre-stress casing, networkspipelines (water supply in ships), sinksealings

Large diameter pipelines, geotextiles |

| Polyvinyl | Poly (vinyl chloride) or polyvinyl chloride (PVC) | Geomembranes, evacuation pipes, water supply pipelines (ship)

various pieces of equipment, sink sealings Profiled joinery (window and closing)

Industrial floor coverings

Geotextile (PS matrix)

Textile architextures, boardings |

| Styrenic and special styrene rubbers | Polystyrene | lighting accessories, thermal isolation of buildings, back fill (on compressible grounds)

Boardings |

| polyvinylidene | (PVDF)

polytetrafluoroethylene (PTFE) | Coil-coating for setting color and protection anti fouling, coextrusion for atmospheric protection of polyolefin polymers

textile archtiecture (PTFE glass) |

| Acrylic derivatives | Polymethylmethacrylate (PMMA)

and derivatives | Noise reducing walls, lighting accessoires, industrial floor coverings, resin mortars |

| Diene polymers (special rubbers) | Polybutadiene and derivatives (EPDM) | Road junctions, bearing mechanisms of works of art, geomembranes |

Polyesters

-saturated

-unsaturated | Copolymers

(unsaturated polyesters - UPE), vinylesters | Geotextiles

Art padding, composites (reinforced by glass fibers), building cladding, industrial grounds |

| Polycarbonates | PC | Noise reducing walls, lighting accories, cladding |

| Polyamides | AP | Geotextiles |

| Polyurethanes | PUR | |

| Polysulfides | ethylene polysulfide of propylene | Reservoir waterproofing, pipelines |

For preparing other polymers, the process becomes increasingly complex, the role of the chemist becomes increasingly important but the reasoning remains the same: use of an oil base, then preparing monomers from this base and other components, and finally formulating and then polymerization. We will see that the “other components” may be ammonia (NH3, itself prepared from nitrogen of the air) for synthesizing polyamides (textile), fluorine (drawn from a rock, fluorspar) for PVDF, and obviously oxygen in the air for various oxidations. We can even use the case of polyamide 11, as an example, which uses castor oil rather than petroleum.

Without going into too much detail, we can however show the various polymers used for manufacturing plastics, rubbers and geosynthetics in tabular form (Table 1.2 above) by categorizing the products into polymer families.

1.1.2. Resins, coatings, paintings

Here, we arrange products used for repair, maintenance, and building heritage conservation.

Products used for repairing concrete can be classified, from a physico-chemical point of view, into two families according to whether the formulation of the base binder is hydraulic, or synthetic resin-based.

In the first family, products containing polymer modified hydraulic binders which make it possible to combine the economic and mechanical performances of hydraulic materials, with the adherence and the flexibility of certain organic materials are widely used. The polymers used here are most often acrylic or vinyl.

In the second family, there are mainly two systems: epoxides (generally of epoxy-amine type) which are very resistant and very adhesive, and polyurethanes which are more flexible and often used for making floor coverings or for waterproofing.

Products used to conserve built surfaces are included in the category of paints and coatings. Let us recall that the researched functions primarily consist of preventing water (possibly charged with aggressive salts) from coming into contact with the structure that needs protecting, whether it a matter of stone, steel or concrete and, in this latter, to also prevent carbon dioxide (CO2) from penetrating the material's pores.

Paint is a film-forming product generally presented in liquid form and is made up of a complex mixture of powdery materials, binders, additives and generally a solvent also called a vehicle:

– the powdery materials include pigments which are responsible for the opacity (covering capacity), the color and possibly an anti-corrosive capacity, and the charges, whose role relates to physical and rheological characteristics; they are generally inorganic;

– the binder is intended to make it possible to coat the powdery materials and to create a film during the drying process; thus here we are dealing with vinyl, glycerophthalic, acrylic, polyurethane, epoxide, silicone, etc. type polymers;

– the additives are used as, thixotropic, anti-skin, fungicide and wetting agents, used in very low doses;

– the vehicle can be an organic solvent (solvent phase paint) or water (water-soluble paints, water-based paint, water-dispersed paint). There may also be no vehicle and, therefore, we are talking about paint without solvent. This last case relates to two component paints, mostly e...