- 473 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Textile Reinforced Concrete

About this book

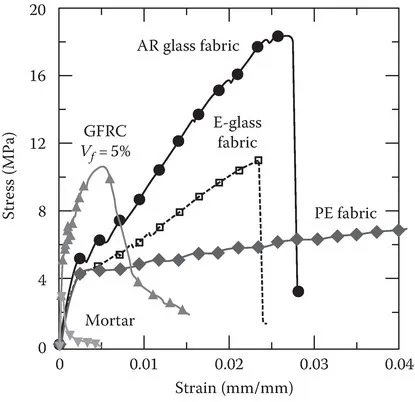

Textile reinforced concrete (TRC) has emerged in recent years as an attractive new high performance cement-based composite. Textiles can significantly improve the mechanical behavior of cement matrices under static and dynamic conditions, and give superior tensile strength, toughness, ductility, energy absorption and protection against environmental degrading influences.

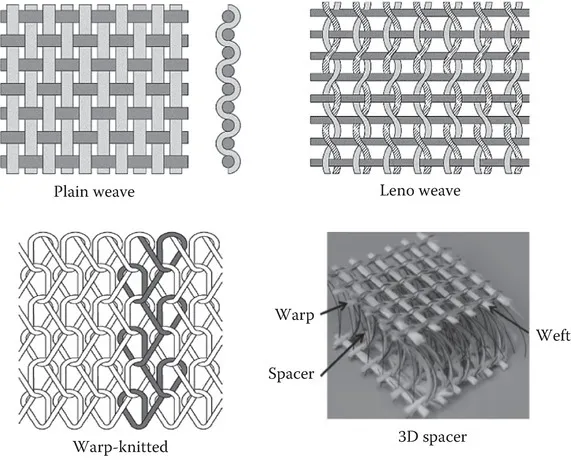

Flexibility with fabric production methods enables the control of fabric and yarn geometry. This, along with the ability to incorporate into the fabric a range of yarns of different types and performances, as well as cement matrix modifications, enables design of the composite to a wide range of needs.

The book is intended to provide a comprehensive treatment of TRC, covering the basic fundamentals of the composite material itself and the principles governing its performance on a macro-scale as a component in a structure.

It provides in-depth treatment of the fabric, methods for production of the composite, the micro-mechanics with special attention to the role of bonding and microstructure, behavior under static and dynamic loading, sustainability, design, and the applications of TRC composites.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Introduction

1.1Structure, properties, and application

Table of contents

- Cover

- Halftitle Page

- Series Page

- Title Page

- Copyright Page

- Contents

- Authors

- 1 Introduction

- 2 Textiles

- 3 Fabrication of TRC

- 4 Micromechanics and microstructure

- 5 Mechanical performance under static conditions

- 6 Mechanics of TRC composite

- 7 Flexural modeling and design

- 8 High rate loading

- 9 Durability of TRC

- 10 Repair and retrofit with TRC

- 11 Innovative applications of textile reinforced concrete (TRC) for sustainability and efficiency

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app