This is a test

- 166 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Book details

Book preview

Table of contents

Citations

About This Book

Cells and organelles are small units for biochemical synthetic purposes, often the smallest practically feasible unit since they contain coenzyme regenerating system, ordered enzyme sequences, etc.These volumes, besides giving some insight into basic technology (immobilisation procedures, etc.), also sum up the current know-how in this subject area and try to predict some future trends.The termimmobilized cells covers everything from dead cells with a single active enzyme species to cells proliferating on or within a three dimensional polymer matrix. The practical handling of these structures make them useful in various applications, e.g. large-scale production of biomolecules, biodegration, analysis, etc.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Immobilized Cells and Organelles by Bo Mattiasson in PDF and/or ePUB format, as well as other popular books in Biological Sciences & Cell Biology. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Immobilized Nonviable Cells for Use of a Single or a Few Enzyme Steps

Stina Gestrelius

TABLE OF CONTENTS

- I. Introduction

- II. Definition

- III. Rationale for Immobilizing Nonviable Cells

- IV. Production of Immobilized Nonviable Cells

- A. Selection of Cells

- B. Production and Recovery of Cells

- C. Selection of Immobilization Method

- 1. Catalyst Application

- 2. Reactor Type

- 3. Enzyme Reaction Conditions and Reactant Properties

- 4. Cell Type and Enzyme Properties

- 5. Catalyst Manufacture

- D. Characterization of the Immobilized Cell Preparation

- V. Present and Future Applications of Immobilized Nonviable Cells

- References

I Introduction

For a process with only one or a few reaction steps the biocatalyst of choice may be a single enzyme, a couple of enzymes, or a cell containing the relevant enzyme(s). To date most industrial biocatalyzed processes are carried out either with soluble, cheap preparations of extracellular enzymes (as e.g., proteolytic, amylolytic or lipolytic enzymes) or by conventional fermentations (steroid conversions, production of gluconic acid, vinegar, etc.).

Very few intracellular enzymes are produced and used industrially, mainly due to severe problems with large-scale isolation procedures.1 Especially membrane-bound enzymes are often solubilized and recovered in too low yields. For utilization of intracellular enzymes from microbial cells it has therefore been a natural approach to use the whole cell material, and a similar development can be expected for plant enzymes (see Chapter 3, Volume I).

In the early industrial applications the cells were used once only. However, by simple flocculation2 or by choosing inherently stable spores3 or fungal pellets4 the cells could be used repeatedly.

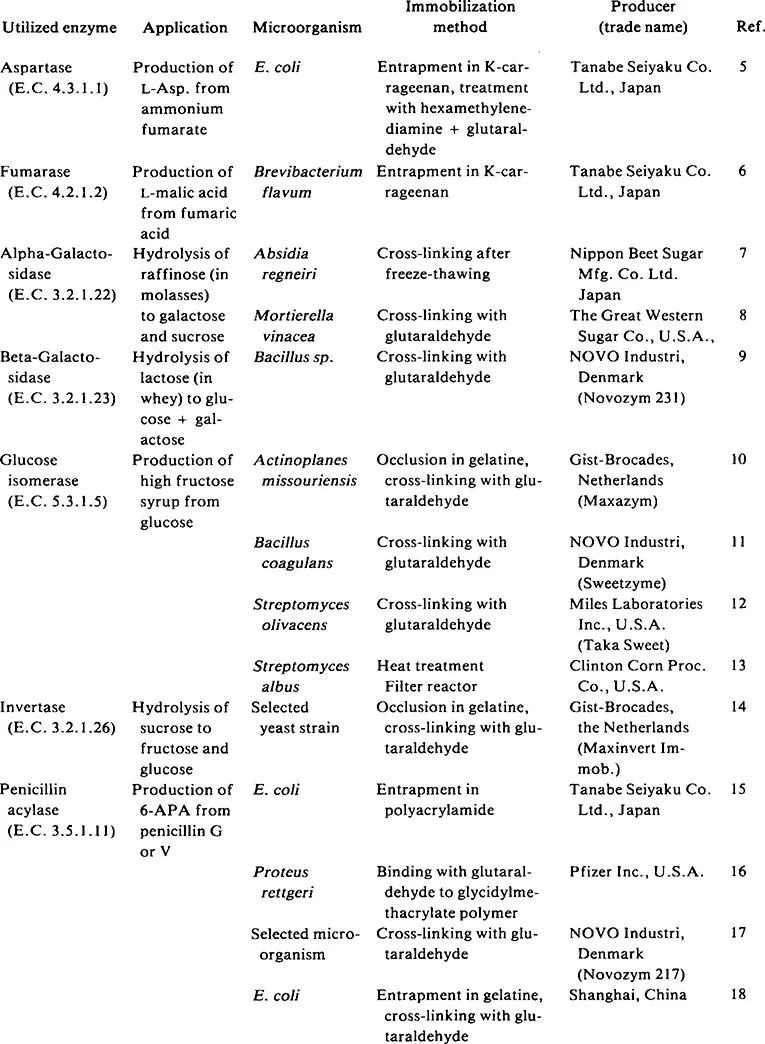

By further physical and chemical treatment leading to a preparation of immobilized nonviable cells, the operational stability has often been improved, thus permitting reuse during increased periods of time (months) while the improved physical stability has allowed a wider choice of reactors and continuous processing. Yet the number of immobilized cell systems, viable or nonviable, that are presently used industrially is very modest. Table 1 lists such commercially operating immobilized nonviable cell catalysts, and it can be noted that the list would not be much longer even if immobilized cell-free enzymes or immobilized viable cells were included. However, except for processes like glucose isomerization where immobilized preparations of enzymes or cells are without competition, the introduction of particulate biocatalysts must be expected to occur only gradually when old plants are replaced, to fulfill new requirements of low energy consumption and increased in-house and environmental safety.

This paper will primarily deal with the interdisciplinary efforts required in developing new biocatalysts of the type immobilized nonviable cells for medium-size or large-scale applications where the keywords are high volumetric activity and good operational stability during continuous processing.

II Definition

An immobilized nonviable cell preparation contains, by the present definition, all or almost all of the original cell components, but may have lost more or less of the original cell organization. The cell structure may have become impaired before, during, or after immobilization, either by physical treatment such as homogenization, lysis, heat-treatment or freeze-thawing, or by treatment with solvents, detergents, or other chemicals.

III Rationale for Immobilizing Nonviable Cells

In addition to the producer’s advantage of immobilizing cells when the desirable enzyme(s) cannot be economically isolated or stabilized in a cell-free form, there must also be one or several technical advantages if the application of a nonviable cell biocatalyst is to become successful. Examples of such advantages include simplified catalyst re-use, smaller reactors, continuous processing, improved catalyst stability, withdrawal of catalyst from product stream, less unit operations in the product upgrading, and cheaper waste treatment.

Table 1 Commercial Immobilized Nonviable Cell Preparations

A number of limitations have also been pointed out, such as difficulties with high molecular weight reactants where soluble enzymes are generally preferred, and difficulties with cofactor retention and regeneration where viable cells may be preferred. Finally such applications, e.g., in medical treatment, where a well-defined catalyst composition is required and a pure (immobilized) enzyme is regarded safer.

For single enzymes without need for cofactors, the immobilization of viable cells is chosen mainly to secure a long lifetime of the catalyst through intermittent reactivation in suitable medium (see Chapter 2, Volume II). However, the application of living cells necessitates the use of very mild immobilization procedures and virtually aseptic application conditions to preclude microbial contamination during reactivation, making this type of catalyst attractive for only few industrial branches. Nonviable cells, on the other hand, can be treated with heat and chemicals to the extent that the enzyme of interest can withstand, permitting the use of a larger number of immobilization methods and sterilization treatments. Other advantages include facilitated mass transport to and from the enzymes after rupturing or permeabilizing the cells, and the potential of inactivating disturbing enzymes to obtain cleaner reactions and improved operational stability (the latter after removing proteolytic enzymes).

Thus, for many single enzyme applications there is a potential of finding a combination of microorganism strain and immobilization procedure that will permit production of a cheap immobilized nonviable cell catalyst with as high volumetric activity and clean reaction pattern as most immobilized enzyme preparations. Also for some multienzyme applications, e.g., of consecutively working enzymes without cofactor requirements, the concept of immobilizing one type of nonviable cells containing all the desired enzymes may prove very favorable.

IV Production of Immobilized Nonviable Cells

A Selection of Cells

Like in all enzyme production a screening program is normally undertaken in order to find the best enzyme source for the application of interest.19

Special emphasis must, however, be put on selecting a cell that is suitable not only for producing the best enzyme, but also for becoming an integrated part of the immobilized preparation. A necessary condition is, of course, that the enzyme of interest is intracellular. While a high enzyme activity per cell is a generally desirable criterium that can often be met by mutational improvement of a strain, the stability during immobilization and the subsequent performance under application conditions are properties that are difficult both to predict and correct.

Takata et al.20 have described a screening program for K-carrageenan immobilized fumarase where 4 strains out of 241 were chosen for thorough investigation of immobilization yields and operational stabilities of the immobilized cells. Each of the four strains (Brevibacterium ammoniagenes, Brevibacterium flavum, Proteus vulgaris, and Pseudomonas fluorescens) was fermented on a separately optimized medium, and the strain that turned out the best choice for catalyst activity and stability was not the one with the highest activity on screening medium. Thus, even with a prechosen immobilization method the selection of the most favorable strain is very time-consuming. When both the cell strain and the immobilization method are to be selected for developing a new nonviable cell catalyst, an iterative approach may be useful21 since test runs with a suboptimal catalyst may help outlining the evaluation criteria. Safety regulations for production and application of microbial cell material (especially food industry regulations) require that microbial strains and fermentation media are selected with great care.22 Pathogenicity and toxicity testing is thus becoming a routine procedure in the industrial strain selection programs. The choice of asporogenic organisms or mutants may reduce viable counts of enzyme/nonviable cell preparations and increase safety in production.19

The absence of interfering enzyme activities is a very important property of cells to be immobilized. Yamamoto et al.23 thus selected a Pseudomonas putida (L-arginine deiminase) for citrulline production since this strain lacked the undesirable ornithine transcarbamylase, and Jack and Zajic24 chose a Micrococcus luteus strain that was free of urocanase for urocanic acid production with His-ammonia lyase.

Permeabilizing treatment causing loss of cofactors has proved effective in removing side activities by cofactor-dependent enzymes. A classical example is bile extract treatment of Brevibacterium ammoniagenes (fumarase catalyst) as described by Yamamoto et al.,25 leading to suppression of unwanted succinic acid formation. Cell rupture treatments in connection with immobilization will be discussed in detail in Section IV.C. below (for references see Table 4).

Heat and pH shocking can sometimes be a selective method for rem...

Table of contents

- Cover

- Title Page

- Copyright Page

- Table of Contents

- Chapter 1 Immobilized Nonviable Cells for Use of a Single or a Few Enzyme Steps

- Chapter 2 Immobilized Viable Cells

- Chapter 3 Oxygenation of Processes Involving Immobilized Cells

- Chapter 5 Co-Immobilization Involving Cells, Organelles, and Enzymes

- Chapter 6 Analytical Applications of Immobilized Cells

- Chapter 7 Cell Membranes as Adsorbents in Affinity Chromatography

- Chapter 8 Process Engineering Considerations in the Development of Immobilized Living Cell Systems

- Index