1.1 What Are Microsystems?[1]

Microsystems may be defined differently by people in different disciplines. The microsys-tems discussed here are the miniaturized functional devices that are based on microelectronics technology, radio frequency (RF) and wireless, optical (or optical electronics), and micro-electro-mechanical systems (MEMS) technologies, and are manufactured, assembled, and integrated on carriers such as a leadframe or a substrate through encapsulation, interconnection, and other microfabrication techniques. As widely applied in the domain of information technology, the microsystems can also be called information technology mi-crosystems. These microsystems consist of consumable electronic products such as calculators, personal computers, cell phones and video products, and information products covering computing products, telecommunication products, automobiles, avionics, and medical electronics. Today’s activities and technical achievements are closely associated with these various integrated multifunctional microsystems.

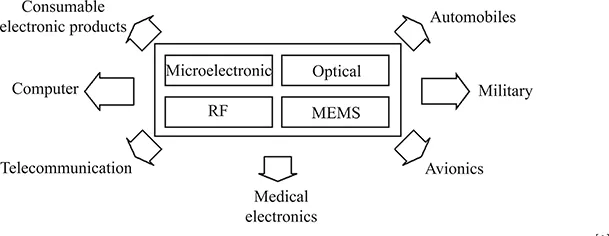

The relationship between microsystem products and their related technologies, including microelectronics, optical electronics, RF, MEMS and packaging technology can be illustrated in Figure 1.1 as follows.

The vigorous development of microsystems is largely attributed to microelectronics achievements, since the invention and commercialization of the very large scale integrated circuit (VLSI) provided manufacturing platforms for miniaturized integrated systems.

Micromanufacturing is one of the essential technologies in microsystems. The micro-fabrication techniques in microelectronics are only part of the basic micromanufacturing techniques, which are determined by the structure difference between microsystems and the microelectronics circuit. A microsystem may include some movable parts, sensing units, and so on, and is usually a complex three-dimensional 3D multifunctional system such as an opto-electro-mechanical system. Integrated circuit manufacturing techniques are mainly two-dimensional or subsurface fabrication on silicon. Therefore, the whole manufacturing process of microsystems, which includes chip fabrication, integration and assembly, and packaging and testing, is much more complicated than those of integrated circuits.

The development of microelectronics technology enables the realization of many electronic products, such as high-speed information processors, large capacity memory, and products with ultralow power consumption. It is expected that future microsystem products will cover

every aspect of our lives. For example, a large number of new products such as intelligent watches with integrated telephone and radio-recorder, multifunctional multimedia personal communication modules, micromedical implants, and minirobots will continuously turn up to meet people’s demands for high-quality life.

1.2 Related Fundamentals of Microsystems

1.2.1 Microelectronics Technology

Microelectronics technology is used to manufacture miniaturized electronic components and circuits based on silicon materials through micron-level processing techniques. Through design and processing with a series of specific techniques, information systems that embody such functions as information gathering, processing, computing, transferring, storing, and execution, are integrated and embedded on silicon chips. Microelectronics is one of the most important fundamental technologies of modern industry, bringing revolutionary change to every walk of life. Its characteristics include:

(1) Strong technology penetration and high value added

When processed from raw material to products of microelectronic component and circuits, the added value increases tremendously.

(2) Sensitive market and short product cycle

Integrated circuits’ development follows Moore’s Law, that is, integration level increasing two times about every 18 months, and feature size decreasing 1.4 times every 3 years.

(3) Intensive technology and high information density

Microelectronics, including its related design, manufacturing, and packaging technologies, is an integration of up-to-date scientific and technological achievements of material, device physics, computer, optics, chemistry, vacuum, precision mechanics, physical and chemical analysis, and so forth.

In 2004, the global semiconductor market reached up to US$ 213 billion. In the first quarter of 2005, the global sales of semiconductors amounted to US$ 54.66 billion, a 14.4% increase over the same period in the previous year, of which Mainland China shared RMB (Renminbi) 77.32 billion. For the Asian-Pacific region, with China as its major part, the first quarter of 2005 saw a remarkable increase rate of 21.9%, the fastest one around the world.

1.2.2 RF and Wireless

Radio and wireless frequency usually ranges from 10 kHz to 1000 GHz. Their evolution can be traced back to the initial wireless transmission experiment made by Marconi in 1901. Wireless transmission frees people from wires and cables completely, and allows communication and information processing anytime and anywhere. Miniaturized, multifunctional, portable and low-cost RF devices have become the key for promotion and application of wireless communication as well as the important application domain of microsystems technology. At the same time, many of the latest noncommunication microsystems, such as advanced RF modules for automobile crash-resistance systems, global positioning system (GPS) modules, etc. have increasingly won the flavor of the market.

1.2.3 Optical Electronics

Optical technology includes acquiring, processing, transmission, and display of optical signals. Optoelectronic technology is an important member of optical technology. As we move into an information society featuring internet linkage and mass data processing, in order to break through the bottleneck of traditional means of signal transmission, optical fiber technology is developing rapidly. The optical fiber technology available now realizes 10 Tbit/s speed for data transmission on a single-mode optical fiber. With wavelength division multiplexing (WDM) technology, the capability of optical signal transmission can be improved greatly. Optical signals with different wavelengths (different colors) being transmitted through the same cable has also been realized. Optical fibers and cables can be applied not only to the trunk communication network, but also to the urban network, community networks, and even household access, which greatly changes life style and improves quality of life of mankind.

1.2.4 Microelectro-mechanical Systems

Micro-electro-mechanical systems (MEMS) are miniaturized devices or systems that usually consist of micromechanisms, microsensors, microactuators, and signal-processing circuit and control circuit, various interfaces, communications, and power. The all-in-one integration of electronic systems and non electronic systems realizes many functions previously unattainable so as to promote the harmonious development of acquiring, processing and handling information. Unlike microelectronics which focuses on two-dimensional fabrication techniques, MEMS lays stress on manufacturing of three-dimensional structure.

MEMS technology uses current microfabrication technology for mass production to produce multifunctional microsystems that are as small as integrated circuits in size. The present MEMS technology possesses the following characteristics:

(1) Diversification of research areas: the research of MEMS technology grows diversified, involving a variety of principles and areas, for example, various microsensors and microac-tuators such as microinertial devices, RF MEMS, microoptical devices, Bio MEMS, data storage, and so on.

(2) Diversification of manufacturing processes: for example, the combination of the traditional silicon bulk micromachining process, surface scarified layer process, silicon-fusion process, combination of deep reactive ion etching trench and bonding; Single Crystal Reactive Etching And Metallization (SCREAM), Lithographie Galvanoformaung Abformung (LIGA) and Ultraviolet-LIGA (UV-LIGA) processing, the metal sacrificial layer process combining thick photoresistance and electroplating technique; the combination of silicon bulk micromachining and surface sacrificed layer process.

(3) Integration of MEMS sensor chips and signal processing circuits in a single chip.

(4) Combined consideration of manufacturing and packaging MEMS chips.

1.3 What Is Microsystems Packaging?[1,2]

Microsystems packaging refers to the techniques with which one or more functional chips or elements are integrated or assembled into application products or modules. Microsystems packaging includes microelectronics packaging, optoelectronics packaging, RF packaging, MEMS packaging, and other multifunction system packaging.

“Packaging” is still very young as a technical term in electronics industry. In the age of vacuum tubes, fixing electron tubes on tube socket to form circuit was generally called “assembly” and no such a term concept as “packaging” existed then. The concept of Mi-crosystems Packaging made its first appearance in microelectronics technology. With the invention of transistors and integrated circuits, protection of the chips was required due to their small size, fragilitys and diversity in functions and specifications. Reliable electrical connections with external circuits became essential with efficient mechanical protection and insulation. The packaging technology thus emerged as the times required.

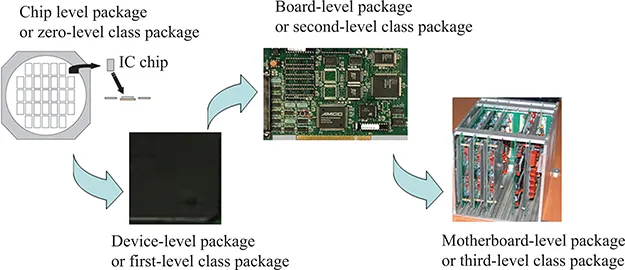

Thus far, no official classification method is available for microsystems packaging. It is usually classified in the community by packaging materials, applications or packaging types, etc. In terms of architecture, microsystems packaging includes several hierarchies: chip-level package (or zero-level package), device-level package (or first-level package), board-level package (or second-level package board-level assembly), and motherboard-level or system level package (or third-level package system package). Figure 1.2 shows the packaging hierarchies in a typical microsystems packaging.

Technically, microsystems packaging involves three kinds of technologies: base chip technology, i.e., microelectronics chips, optoelectronics chip, MEMS chip, RF chip, etc., system engineering technology, and system packaging technology. The “chips” are functional elements of various kinds, and “system” all the object products, while “packaging” refers to connecting “chips” and other devices to system substrate to form object products. As for design and manufacturing technology of the “chips”, which has been specifically discussed in other publications, they are beyond the scope of this book and hence are not included.

Figure 1.3 illustrates the chips, systems, and packaging mentioned above, and their relations. The area where chips and packaging overlap denotes the “...