This is a test

- 152 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Rockbursts in Coal Mines and Their Prevention

Book details

Book preview

Table of contents

Citations

About This Book

The preventive methods described have proved highly effective. They comprise laying out the workings in such a way as to minimize dangerous concentrations of ground stresses, and early elimination by means of blasting, drilling, or water infusion. An account of these methods as applied in German coal mines, the deepest in the world. Contents: Rockbursts & similar phenomena; Conditions of occurrence; Influence of rock stress; Bursting & nonbursting coal; Long-term prevention; Direct prevention; Borehole patterns for direct prevention; Destressing methods; Case histories.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Rockbursts in Coal Mines and Their Prevention by Gerhard Braeuner in PDF and/or ePUB format, as well as other popular books in Technik & Maschinenbau & Bauingenieurwesen. We have over one million books available in our catalogue for you to explore.

Information

CHAPTER 1

Rockbursts and similar phenomena

Rockbursts are violent failures in the ground, breaking rock and expelling it into excavations. Other definitions describe the phenomenon as a special seismic event or as some rheological process, thus aiming at a more general classification. The term is, however, descriptive and rather self-explanatory: broken rock - in coal mines, broken coal - bursts into mine workings from the sides, roof, or floor, this happening suddenly and in an explosive manner. Other terms are ‘bump’, ‘mountain bump’, ‘air blast’, or simply ‘burst’. Rockbursts are mainly encountered in ore, coal, and potash mines, also in tunnels or caverns in hard competent rock like granite or quartzite. The quantity of broken rock ranges from a few tons to thousands of tons.

Every rockburst is accompanied by a loud report and a ground tremor - a seismic shock - the strength of which varies with the strength of the burst. Tremors from major rockbursts are felt on the surface, but even vibrations from slight rockbursts can be recorded by seismic stations. The strongest tremor yet recorded, having a seismic magnitude of 5.6 (Richter scale), resulted from a large rockburst in a potash mine.

On the other hand, the great majority of ground tremors induced by mining are not due to rockbursts. They appear to result from fracture processes in the course of subsidence of undermined hard strata. For example, in the Ruhr District 4623 seismic events were localized by earthquake stations from 1983 to 1992; the greatest number of them were not even noticed underground, and only 18 rockbursts occurred during this ten-year period. In brief, a rockburst always causes a ground tremor, but most tremors are not caused by rockbursts.

Another symptom of rockbursts is a gust of air, in some cases so strong that the term ‘air blast’ is used synonymously for rockburst. Such blasts can whirl up large quantities of dust and may impair the ventilation; in some instances they feel like air discharged from a compressed-air line.

The rockbursts in coal mines are violent failures of the coal seam, causing ejection of broken coal and often taking the form of an abrupt movement of the face or sidewall. They may therefore more appropriately be designated as ‘coal bursts’. Sometimes they are accompanied by immediate floor heave or, less frequently, by sudden roof fall. The hazard of explosion may arise from the escape of flammable gas and the lifting of coal dust. Large rockbursts have released up to 105 m3 of methane.

The gas release can give rise to mistaking such rockbursts for outbursts of gas and coal. There is indeed some resemblance. These so-called gas-coal-outbursts are sudden emissions of gas - mostly methane or carbon dioxide -which involve the ejection of disintegrated coal and leave longish cavities in the seam. The most characteristic features which distinguish them from rockbursts are as follows:

- - The process is slower and less violent.

- - There is no or relatively little seismic reaction.

- - The ejected coal is broken into even smaller particles.

- - Occurrence is predominantly associated with geological disturbances.

The coal usually comes out of an advancing face or its close vicinity whereas rockbursts may also come out of sidewalls or pillars. A necessary (not a sufficient) precondition is, of course, that the seam contains enough gas - e.g. at least 10 m3 of methane per ton of solid coal. This has no bearing on rockburst occurrence in most coalfields.

Another similarly sudden phenomenon is gas-rock-outburst, which ejects crushed rock instead of coal. In coal mines, the outbursts mostly come out of gas-bearing sandstone strata and leave typical cavities with marked patterns of fracturing not related to the structure of the sandstone in the sides. Such cavities and the masses of crushed stone are unmistakable and help to identify the event.

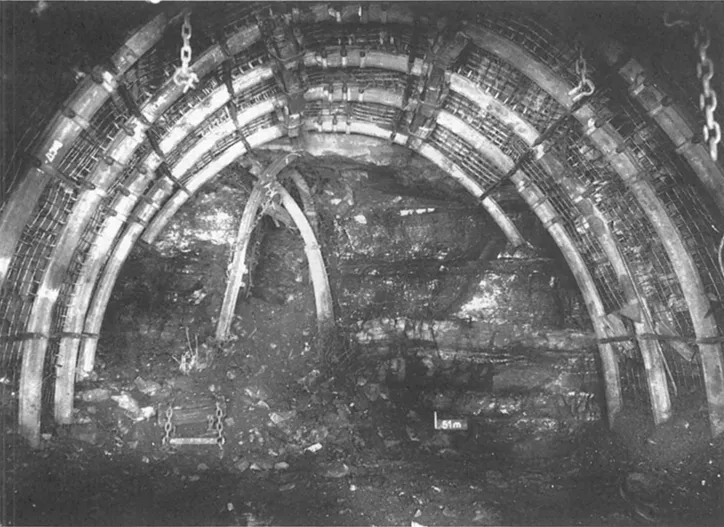

Fig. 1.1 shows a roadway after a major rockburst. The roadway was located in a flat seam 3 m thick and is now being restored to its former cross-section, namely 6 m wide and 3 m high. The seam burst in simultaneously from both sides, thus nearly closing the roadway. About 15 m farther ahead, in Fig. 1.2, the roadway is still narrowed to a hardly passable hole. The seam looks as if it had expanded as an intact mass from both sides. This appearance is not uncommon when the deformed steel arches or props still prevent the coal fragments from falling; otherwise the coal would be more disintegrated and scattered. No fracture in either roof or floor was involved. The destructive effects of this burst extended over a length of 50 m in the roadway; about 42 000 m3 of methane was released.

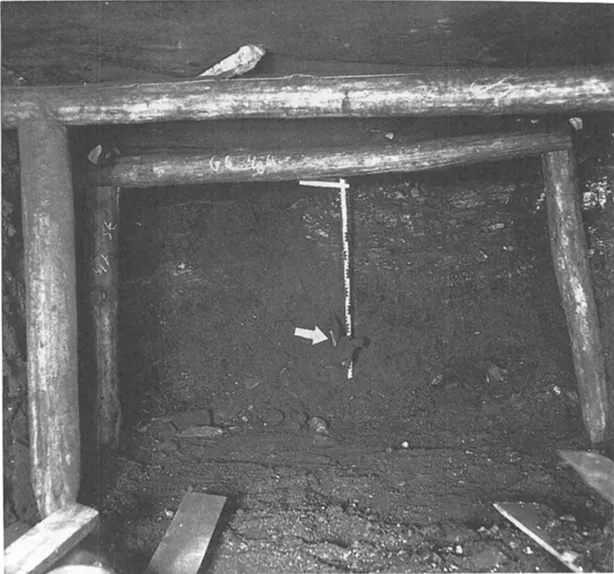

A similar but more disastrous example of a rockburst is illustrated in Fig. 1.3. In this heading, the coal from both sides met in the middle, leaving no void and even pressing the compressed air pipe flat (arrow). The heading was 1.6 m high (the seam thickness) and originally 2.5 m wide; it was closed totally over a distance of 160 m (see also p. 10 f.). The photo clearly shows that the roof and the floor remained stable.

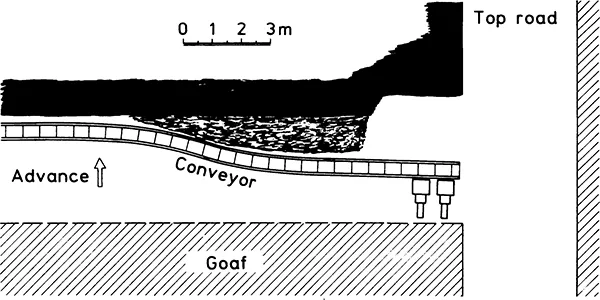

The majority of rockbursts are less severe yet still involve a hazard to personnel. Fig. 1.4 shows, in plan view, a very slight rockburst which came out of a prop-free longwall face in a seam 2 m thick. In the burst zone, for a distance of 8 m, the face collapsed into a slope of fragments (the darkened area in Fig. 1.4) and shifted the conveyor towards the goaf (goaf = extracted area, mined-out area). The upper third of the seam was nearly pulverized, the rest was broken to a greater or lesser degree.

Fig. 1.1. Roadway nearly closed by rockburst.

Fig. 1.2. Roadway in Fig. 1.1, about 15 m farther.

Fig. 1.3. Rise heading closed by a rockburst.

Fig. 1.4. Slight rockburst out of a longwall face (plan view).

Fig. 1.5 Gas-coal-outburst in a rise heading.

When a similar disintegration of coal is associated with considerable emission of gas, the event might be taken for a gas-coal-outburst. The coal from such outbursts, as shown in Fig. 1.5, resembles to some extent the coal from rockbursts coming out of unsupported faces or sidewalls. The outburst in Fig. 1.5 came out of the advancing face of a rise heading and discharged about 60 tons of coal and 300 m3 of methane. The movement of the coal did, however, not happen suddenly but instead lasted several minutes, and no ground shock was felt. From these symptoms the process can be clearly identified as a gas-coal-outburst.

There are also unstable failure processes slower than rockbursts or gas outbursts but faster than normal convergence. They begin in a series of slight but sudden and audible fractures and movements of the coal and the adjacent rock and may lead to considerable closure of the excavation in a few hours. In the example shown in Fig. 1.6 the floor of the roadway heaved 0.8 m within 24 hours while the seam moved 0.5 m inward from both sides. The roadway was 6 m wide and the seam 1.9 m thick. The photo was taken 17 days later when the floor had heaved an additional 1 m so that the roadway was almost completely closed off. Although such processes usually come to an end within some days, they should lead to closer investigations into ground stresses and geological conditions. The evident tendency to unstable reactions may involve rockburst danger in case of more resistant over- and underlying strata.

Fig. 1.6 Rapid convergence of a roadway.

The appearance of rockbursts depends largely on local conditions. Sudden floor heave is relatively often involved if there are underlying coal beds. Soft layers between the seam and the main roof are liable to break down. In steep seams, the coal falls in loose masses leaving irregularly shaped cavities. Even though the geological conditions may be alike, there is still the influence of mining factors: pillars may burst on two or more sides, roadways are more susceptible to bursts from either side than from the face, and longwall faces are less damaged by minor bursts when powered supports are used. Finally, it depends on geological and on mining conditions as to whether bursts can occur at all. This leads to the following chapters.

CHAPTER 2

Conditions of rockburst occurrence

2.1 NATURAL CONDITIONS

Roof and floor strata

The feature most common to seams in which rockbursts occur is the close proximity to strong, thick and rather rigid strata. In most coalfields these strata consist of sandstone, in rarer cases they consist of other types of what has been defined as competent massive elastic rock (Obert and Duvall 1967, p. 467 f.). They need not necessarily be in direct contact with the seam, although intervening softer strata may reduce the danger. A main roof consisting of such rock and beginning within a few metres above the seam is found almost without exception; strong, massive beds in the floor are not so common. From investigations at rockburst sites the following conditions have been found in coal mining districts.

Coalfields in the United States: The overlying strata usually contain massive beds of sandstone more than 10 m thick. The uniaxial compressive strength of specimens from several beds was found to be about 100 MPa and the modulus of elasticity about 25 000 MPa (Holland 1958).

Former Soviet Union (where rockbursts have been experienced in at least seven coalfields): The roof is massive and at least 8 m thick; the uniaxial compressive strength obtained in laboratory tests ...

Table of contents

- Cover Page

- Half title

- title

- copy

- preface

- Preface

- 1 Rockbursts and similar phenomena

- 2 Conditions of rockburst occurrence

- 3 The influence of rock stresses

- 4 Bursting and nonbursting coal

- 5 Long-term prevention

- 6 Direct prevention

- 7 Borehole patterns for direct prevention

- 8 Destressing methods

- 9 Case histories