- 992 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Mine Planning and Equipment Selection 2000

About this book

This text looks at mine planning and equipment and covers topics such as: design and planning of surface and underground mines; geotechnical stability in surface and underground mines; and mining and the environment.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Assessment of vibration measurements due to blasting of the hard formations at the South Field Lignite Mine, Ptolemais, Greece

Department of Mineral Resources Engineering, Technical University of Crete, Hania, Greece

Lignite Center of Ptolemais-Amydeon, Public Power Corporation, Ptolemais, Greece

ABSTRACT: Drilling and blasting procedures are utilized for removing various types of overburden hard formations at the South Field Lignite Mine, at the Lignite Center of Ptolemais-Amydeon, operated by the Greek Public Power Corporation. This paper presents the results and experiences from a blast vibration program that was recently initiated in order to ensure that the surface blasting operations do not affect a powerplant as well as a village that are located in close proximity to the surface mining operations. Additionally, results of this program were utilized to redesign the blasts to achieve lower vibration levels.

1 INTRODUCTION

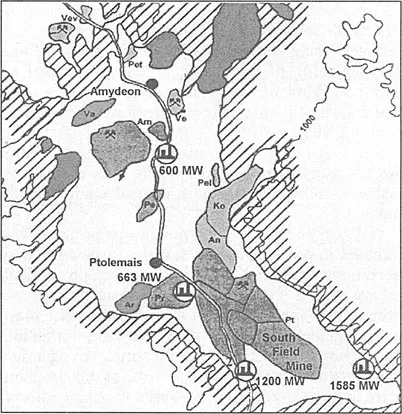

Greece is the fifth largest producer of soft brown coal in the world and the second largest in the European Community, producing about 61Mt of lignite per annum. The Lignite Center of Ptolemais-Amydeon (LCP-A), operated by the Greek Public Power Corporation (PPC), is located in northern Greece, about 110km west of the city of Thessaloniki. The lignite deposits under exploitation cover an area of 120km2, including 4000Mt of proven geological reserves and 2500Mt of exploitable lignite under current economic and technological criteria. Today, the LCP-A manages four large active mining units, which produce lignite to cover 62% of the power generation in Greece. At the present rate of extraction, 50Mt of lignite are produced annually (comprising about 80% of the total lignite extraction in Greece), by moving a total of 250Mm3 of earth material.

The South Field Mine is the largest of the four operational surface mines at the Lignite Center of Ptolemais-Amydeon, covering an area of 24km2 (Fig. 1). The original lignite deposit in the area was estimated at 1.2 billion tons of lignite. Mining operations commenced in August 1979 and currently the mine operates on ten benches, using mainly the continuous mining method, which employs bucket wheel excavators (BWEs), conveyors and stackers. Also conventional mining equipment including big trucks, front end loaders, electric rope and hydraulic shovels, dozers are utilized for mining the hard rock formations which are encountered in the overburden strata.

Figure 1. Location of the South Field Mine in the lignite bearing Ptolemais – Amydeon valley.

The South Field Mine, can be considered unique regarding the mining conditions and the technologies used to exploit the orebody. More specifically, benches 1a, 11a, 1b, 2a, 2b and 3 excavate overburden, while benches 4, 5, 6a, 6b and 7 excavate the lignite seams. The mine uses 65 conveyor belts with a total length of 100km. Mining depth is expected to reach 200m. The scheduled annual lignite production at the South Field Mine reaches 18–20Mt lignite, while overburden removal operations produce annually 47–53Mm3 of bank material, to achieve total annual excavations of 90Mm3 of earth material.

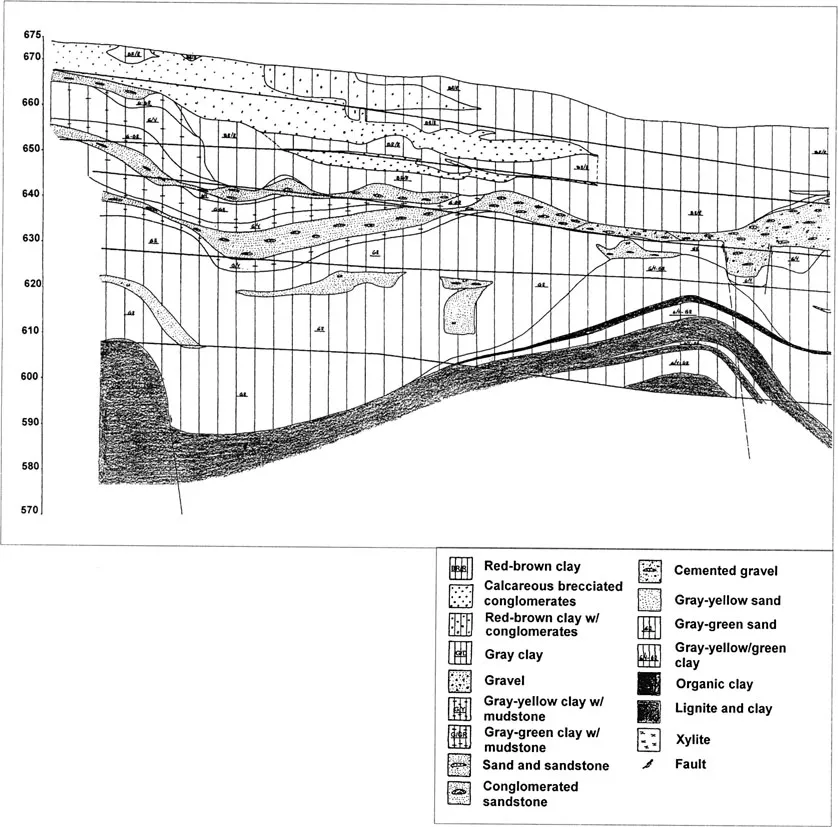

Figure 2. Typical cross-section of overburden material

Approximately 25–30% of the overburden consists of hard and semi-hard formations, which are removed using conventional mining methods. Since the beginning of mining operations to the end of 1999, 917Mm3 of total earth material were moved and 200Mt of lignite were produced with an average exploitation ratio of 3.75:1.

As early as 1981, it was decided to use large scale explosives to loosen the hard rock formations and use conventional load and haul equipment to move it.

In 1996 a blast vibration monitoring program was initiated in order to ensure that the surface blasting operations would not affect in any way a powerplant as well as a village that were located in close proximity to the mine face. Additionally, since blast design guidelines for blasting the hard formation lenses, which occur within softer overburden materials, were not available, results of this program were utilized to redesign the blasts to achieve lower vibration levels.

Results of the blast vibration program at the South Field Mine, are presented and critically evaluated regarding surface blast design and implementation. It should be noted that, currently, maximum vibration levels as well as air-blast levels are below the limits set by DIN 4150 and OSMRE.

2 OVERBURDEN LITHOLOGY

Overburden strata consist of fine and coarse clastic sediments such as clays, marls, gravel, conglomerates with embedded hard layers of sandstones, cemented conglomerates and mudstones (Figure 2). The average in site specific weight of the overburden is 19.62kN/m3 (2ton/m3) and the average bulking factor ranges from 1.4 to 1.5. The average thickness of overburden material in that area is 90m. Table 1 shows the range of the mechanical and physical properties of the hard rock formations, while Table 2 shows the approximate extend of each formation in the South Field Mine. Table 3 summarizes the conventional equipment used in overburden removal.

Table 1. Physical and mechanical properties for the hard formation material

Parameter | Range value |

Uniaxial compressive strength (MPa) | 15–143 |

Tensile strength (MPa) | 2.4-11.2 |

Density (ton/m3) | 2.4-2.7 |

3 BLASTING PROCEDURES

Currently, five blasthole rigs (Tamrock C50 K3L) are utilized, drilling over 1000 m of blastholes per day at 7 7/8 and 9 in diameter for 4x5m or 6x6m blasthole grids. About 1600 tons of explosives are consumed annually by detonating about 700 shots. That corresponds to 2–3 blasts per day with an explosives load of 1–8 tons per blast. Drillheads are air-cooled tricones (IADC 622), with embedded carbide bids.

Originally blasting was accomplished utilizing ANFO mixes with either ammonia dynamite (extra dynamite) products or gelatin dynamite (30% weight strength) for boosters. Wet holes were loaded with 30% weight strength gelatin dynamite.

In 1995, South Field Mine engineers used for the first time a special mix of ANFO and emulsion called Heavy A...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Foreword

- Organization

- 1 Design and planning of surface and underground mines

- 2 Mining geostatistics and mine optimisation

- 3 Geotechnical stability in surface and underground mines

- 4 Mine evaluation – Financial and management issues

- 5 Mine equipment selection

- 6 Innovative mining systems – Machine automation

- 7 Information technologies in mining

- 8 Mining and the environment

- Author index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Mine Planning and Equipment Selection 2000 by T.N. Michalakopoulos,G.N. Panagiotou in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.