This is a test

- 220 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Extrusion Of Foods

Book details

Book preview

Table of contents

Citations

About This Book

First Published in 1981, this two-volume set explores the extrusion of foods. Carefully compiled and filled with a vast repertoire of notes, diagrams, and references this book serves as a useful reference for students of medicine and other practitioners in their respective fields.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Extrusion Of Foods by Judson M. Harper in PDF and/or ePUB format, as well as other popular books in Technik & Maschinenbau & Lebensmittelwissenschaft. We have over one million books available in our catalogue for you to explore.

Information

Volume I

Chapter 1 Food Extrusion

Chapter 2 The Food Extruder

Chapter 3 Dough Rheology

Chapter 4 Extrusion Models

Chapter 5 Residence Time Distribution and Strain

Chapter 6 Extrusion Measurements and Experimentation

Chapter 7 Extrusion Equipment

Chapter 8 Extrusion Operations

Appendix 1 Symbols and Greek Letters

Appendix 2 Conversion Factors

Appendix 3 Properties of Water

Volume II

Chapter 9 Colors, Flavors, and Additives

Chapter 10 Macaroni Extrusion

Chapter 11 Extrusion of Starches and Starchy Materials

Chapter 12 Starch-Based Extruded Foods

Chapter 13 Textured Plant Proteins

Chapter 14 Nutritious High Protein Foods

Appendix 1 Symbols and Greek Letters

Appendix 2 Conversion Factors

Appendix 3 Properties of Water

Chapter 1

Food Extrusion

I. Introduction

Webster’s defines the verb to extrude, as “to shape by forcing through a specially designed opening often after a previous heating of the material.”6 Extrusion, therefore, is primarily oriented toward the continuous forming of plastic or soft materials through a die. An extruder is a machine which shapes materials by the process of extrusion.

Several designs are possible for extruders. The simplest is a ram or piston extruder. The principal focus for this book involves screw extruders consisting of flighted screw(s) or worm(s) rotating within a sleeve or barrel. The action of the flights on the screw pushes the platicized material forward and creates the pressure behind the discharge die so that it extrudes through the opening.

Cooking extrusion combines the heating of food products with the act of extrusion to create a cooked and shaped food product. Cooking extrusion can be described as a process whereby moistened, starchy, and/or proteinaceous foods are cooked and worked into a viscous, plastic-like dough. Cooking is accomplished through the application of heat, either directly by steam injection or indirectly through jackets, and by dissipation of the mechanical energy through shearing occurring within the dough. The results of cooking the food ingredients during the extrusion process are the gelatinization of starch, the denaturation of protein, the inactivation of many raw food enzymes which can cause food deterioration during storage, the destruction of naturally occurring toxic substances such as trypsin inhibitors in soybeans, and the diminishing of microbial counts in the final product.

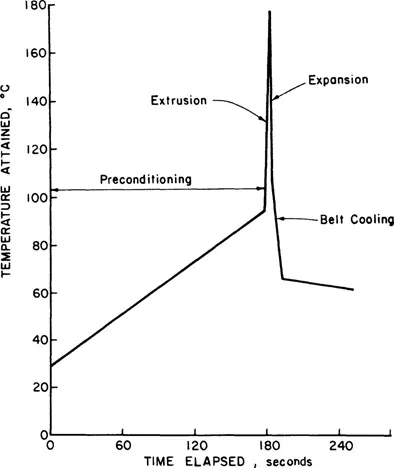

The temperatures reached by the food during cooking extrusion can be quite high (200°C) but the residence time at these elevated temperatures is very short (5 to 10 sec) as illustrated in Figure 1. For this reason, extrusion processes are often called HTST (high-temperature/short-time). They tend to maximize the beneficial effects of heating foods (improved digestibility and instantization [precooking]), while minimizing the detrimental effects (browning, inactivation of vitamins and essential amino acids, production of off-flavors, etc.). Once cooked, the product is forced through a die at the extruder discharge where it expands rapidly with some loss in moisture because of a rapid decrease in pressure. After expansion and cooling/drying, the extrudate develops a rigid structure and maintains a porous texture.

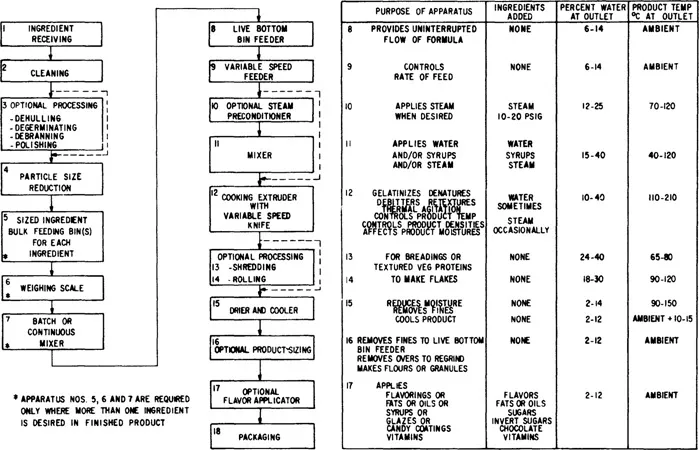

A schematic flow diagram of a cooking extruder process is shown in Figure 2 along with ranges of product moistures and temperatures. In the extrusion processing plant, raw ingredients consisting primarily of cereals and proteinaceous oil seeds are received, cleaned/dehulled, stored, blended, and fed to the extruder. Optional preconditioning with water or steam follows. The extruder cooks and/or forms these ingredients to yield expanded textured products or cooked dough pellets which require further processing. Drying or toasting followed by flavor and/or other ingredient addition completes the typical extrusion process.

II. Advantages

The principal advantages of the modern food extruder, leading to their expanded role in the food processing industry, were given by Smith.3 This list, which has been expanded and broadened, is given below.

- Versatility — A wide variety of foods can be produced on the same basic extrusion system using numerous ingredients and processing conditions.

- High productivity — An extruder provides a continuous processing system having greater production capability than other cooking/forming systems.

- Low cost — Labor and floor space requirements per unit of production are smaller than for other cooking/forming systems enhancing cost effectiveness.

- Product shapes — Extruders can produce shapes not easily formed using other production methods.

- High product quality — The HTST heating process minimizes degradation of food nutrients by heat while improving digestibility by gelatinizing starch and denaturing protein. The short, high-temperature treatment also destroys most undesirable factors in food. Some of these heat denaturable factors are antinutritional compounds such as trypsin inhibitors, hemagglutinins, and gossypol, and undesirable enzymes such as lipases or lipoxidases, microorganisms and other food-borne pests.

- Energy efficient — Extrusion processing systems operate at relatively low moistures while cooking food products. Lower moisture reduces the quantity of heat required for cooking and redrying the product after cooking.

- Production of new foods — Extruders can modify vegetable proteins, starches, and other food materials to produce a variety of new food products.

- No effluents — The lack of process effluents is an important advantage since stringent controls are being placed upon food processors to prevent their releasing pollutants to the environment.

III. History of Food Extrusion

The first food extrusions involved the use of piston or ram-type extruders to stuff casings in the manufacture of sausages and processed meats. The development of the simple food chopper or mincer, consisting of a screw which forces soft food products through a die plate, may have been the first use of a single-screw food extruder. Interestingly, these two early examples of food extruders used by the meat industry exist today in remarkably similar forms. The design of the ram and chopper are relatively simple with recent developments being focused on increased capacity, materials of construction, sanitary design, simplified means of feeding, and improved driving parts such as automated hydraulic activators or electrical motors.

Hydraulically operated batch cylindrical ram macaroni presses came into existence around 1900. They represent the second major food industry to adopt the use of extruders after their initial applications in meat processing.

Rolling or sheeting operations can also be broadly classed as an extrusion process to form cereal dough products which date back to antiquity. The action of two counter-rotating rolls, working toward a restriction or a narrow gap separating them at their nip, effectively shape the dough products while achieving high pressures and shear rates. Rolls have been used to continuously pressurize doughs which are then forced through a nozzle to accomplish forming operations. Ziemba5 gives several examples where roll-type extruders are applied to form cookies, crackers, confections, marshmallows, and cheese slices.

The initial application of the single-screw extruder, which revolutionized an entire industry, was its use as a continuous pasta press in the mid 1930s. The pasta press mixes semolina flour, water, and other ingredients forming a uniform dough. The screw of the extruder also works the dough and forces the mixture through specially designed dies to create the variety of pasta shapes which are now available. Low shear extrusion screws, characterized by deep screw flights, cause little heat or precooking to occur in the dough.

General Mills, Inc. was the first to use an extruder in the manufacture of ready-to-eat (RTE) cereals in the late 1930s. Initially, RTE cereals only utilized the extruder to shape a precooked cereal dough into a variety of cereal shapes which were dried and subsequently puffed or flaked. Here, the extruder performed a function similar to the pasta extruder by shaping the hot, precooked cereal dough.

Expanded corn collets or curls were first extruded in 1936 but the product was not commercially developed until 1946 by the Adams Corp.Ⓡ Collet extruders are characterized by an extremely high shear rate within the flights of the screw and grooves in the barrel. No external heat is applied through jackets around the barrel and the entire heat input comes from the viscous dissipation of mechanical energy applied to the shaft of the extruder. Such extruders are often classified as autogenous. The typical collet extruder has its operation limited to low-moisture ingredients and the production of highly expanded snack products. To add to the variety of products made on collet extruders, rice and potato flours as well as a number of starches are used to create numerous shapes including puffs, rings, and French fries.

The desire to precook animal feeds to improve digestibility and palatability led to the development of the cooking extruder in the ...

Table of contents

- Cover

- Title Page

- Copyright Page

- Preface

- The Author

- Dedication Page

- Table of Contents

- Volume I

- Chapter 1 Food Extrusion

- Chapter 2 The Food Extruder

- Chapter 3 Dough Rheology

- Chapter 4 Extrusion Models

- Chapter 5 Residence Time Distribution and Strain

- Chapter 6 Extrusion Measurements and Experimentation

- Chapter 7 Extrusion Equipment

- Chapter 8 Extrusion Operations

- Appendix 1 Symbols and Greek Letters

- Appendix 2 Conversion Factor

- Appendix 3 Properties of Water

- Index