eBook - ePub

Production and Operations Analysis

Traditional, Latest, and Smart Views

This is a test

- 634 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Book details

Book preview

Table of contents

Citations

About This Book

The aim of this book is to cover various aspects of the Production and Operations Analysis. Apart from the introduction to basic understanding of each topic, the book will also provide insights to various conventional techniques as well as, various other mathematical and nature-based techniques extracted from the existing literature. Concepts like smart factories, intelligent manufacturing, and various techniques of manufacturing will also be included. Various types of numerical examples will also be presented in each chapter and the descriptions will be done in lucid style with figures, point-wise descriptions, tables, pictures to facilitate easy understanding of the subject.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Production and Operations Analysis by Susmita Bandyopadhyay in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Engineering. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction to Production and Operations Concept

1.1 Introduction

The study of production and operations analysis is required for every student, researcher, and practitioner of the relevant fields of study. The basic concepts are required to be known in order to understand the basic tasks properly. However, each company has some position in the existing market and faces market competition from its competitors. Therefore, appropriate strategies and policies must be adopted by every company in order to sustain in this competitive business world. However strategies are long-term goals for a company. The strategies adopted by a company need to be understood by every employee within the company and the strategy must be converted to small short-term objectives to fulfill.

This chapter gives brief introduction to production and operations management. Production management is the set of activities that are required to produce certain products. If the same concept is also extended to services management, then the corresponding set of management activities is called as operations management. In other word, the concept of production is a subset of the concept of operations. “Operations” is applicable to all fields of study and practice, such as marketing operations, financial operations, and many more. Similarly, “production” is also another operation. Thus, the term operation draws a peripheral concept that also includes production operation.

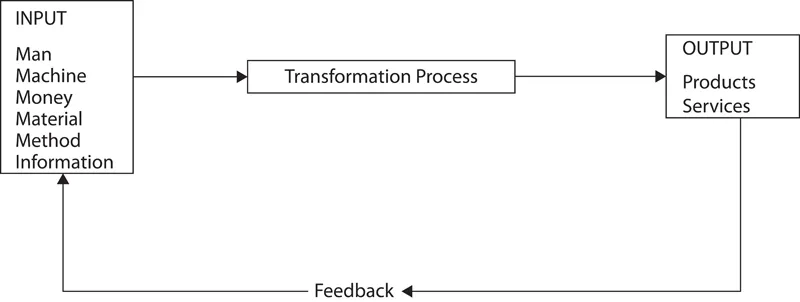

Production is the process of converting raw materials to finished goods by using various other resources as shown in Figure 1.1. Edwood Buffa defines production as “a process by which goods and services are created.” Some examples of production and operations are manufacturing custom-made products like boilers with a specific capacity, constructing flats, some structural fabrication works for selected customers, etc., and manufacturing standardized products like car, bus, motor cycle, radio, television, etc.

Production process.

The production system has the following characteristics:

1. Production is an organized activity, so every production system has an objective.

2. The system transforms the various inputs to useful outputs.

3. It does not operate in isolation from the other elements of the system.

4. There exists a feedback for the activities, which is essential to control and improve system performance.

There are various types of production systems. The next section depicts the different types of production systems.

1.2 Types of Production Systems

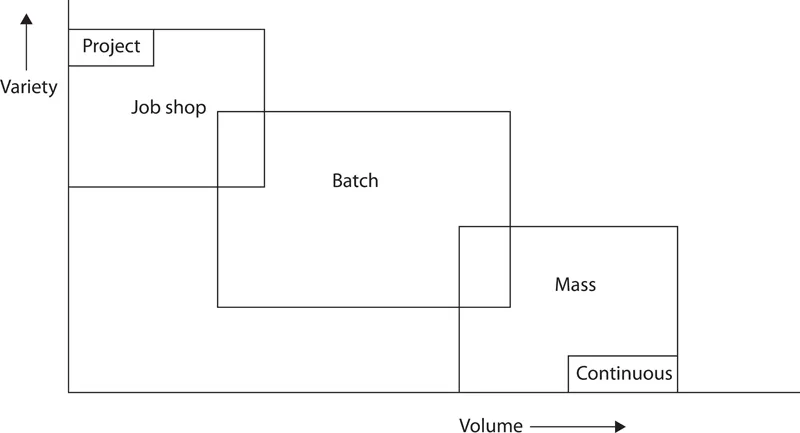

Production systems are categorized into the following types (Figure 1.2).

• Project type: Project type is characterized by very high variety, very low volume production. Examples may include the production of airplanes, ships, etc.

• Job shop type: Job shop type of production is characterized by high variety, low volume of production. This type of production system handles job order as they come (make-to-order strategy) and the end product is different at every time (or most of the time). Examples include automobile manufacturing.

• Batch type: Batch type of production is characterized by medium volume, medium variety production. For this type, the demand rate is generally less than rate of production. The batch size is either determined by forecasting or by order size. This type of production system requires skilled labor and less supervision.

• Mass: Mass type of production is characterized by low variety, high volume production. The demand rate is generally greater than the rate of production. The methods used are standardized methods, and semiskilled labor may be employed for supervision only.

• Continuous: Continuous type of production is characterized by very low variety and very high volume of production. Examples include the production of liquid products.

The basic characteristics of job shop production are the manufacturing of one or few number of products designed and produced as per the specification of customers within predecided time and cost. The distinguishing feature of this is low volume and high variety of products. The main characteristics of job shop production are enlisted below.

1. High variety of products and low volume.

2. Use of general-purpose machines and facilities.

3. Highly skilled operators who can take up each job as a challenge because of uniqueness.

4. Large inventory of materials, tools, and parts.

5. Detailed planning which is essential for sequencing the requirements of each product, capacities for each work center and order priorities.

Types of production.

The basic advantages and disadvantages of job shop production are shown below.

Advantages:

1. Because of general-purpose machines and facilities, variety of products can be produced.

2. Operators will become more skilled and competent, as each job gives them learning opportunities.

3. Full potential of operators can be utilized.

4. Opportunity exists for creative methods and innovative ideas.

Disadvantages:

1. Higher cost due to frequent setup changes.

2. Higher level of inventory at all levels and hence higher inventory cost.

3. Production planning is complicated.

4. Larger space requirements.

The characteristics, advantages, and disadvantages of batch production are shown below.

Characteristics:

1. Batch production is applicable when there is shorter production runs.

2. Batch production is applicable when plant and machinery are flexible.

3. Batch production is applicable when plant and machinery setup is used for the production of item in a batch and change of setup is required for processing the next batch.

4. Batch production is applicable when manufacturing lead time and cost are lower as compared to job order production.

Advantages:

1. Better utilization of plant and machinery.

2. Promotes functional specialization.

3. Cost per unit is lower as compared to job order production.

4. Lower investment in plant and machinery.

5. Flexibility to accommodate and process number of products.

6. Job satisfaction exists for operators.

Disadvantages:

1. Material handling is complex because of irregular and longer flows.

2. Production planning and control is complex.

3. Work-in-process inventory is higher compared to continuous production.

4. Higher setup costs due to frequent changes in setup.

The characteristics, advantages, and disadvantages of batch production are shown below.

Characteristics:

1. Standardization of product and process sequence.

2. Dedicated special-purpose machines having higher production capacities and output rates.

3. Large volume of products.

4. Shorter cycle time of production.

5. Lower in-process inventory.

6. Perfectly balanced production lines.

7. Flow of materials, components, and parts is continuous and without any back tracking.

8. Production planning and control is easy.

9. Material handling can be completely automatic.

Advantages:

1. Higher rate of production with reduced cycle time.

2. Higher capacity utilization due to line ba...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- List of Figures

- List of Tables

- Preface

- Author

- 1 Introduction to Production and Operations Concept

- 2 Study of Techniques

- 3 Introduction to Smart Manufacturing

- 4 Forecasting

- 5 Aggregate Planning

- 6 Facility Location

- 7 Facility Layout

- 8 Master Production Scheduling

- 9 Material Requirement Planning

- 10 Just-in-Time and Kanban

- 11 Capacity Planning

- 12 Inventory Control Systems

- 13 Materials Management

- 14 Material Handling Systems

- 15 Production Planning and Control

- 16 Scheduling

- 17 Project Scheduling

- 18 Quality Management

- 19 Reliability and Maintenance Management

- 20 Total Quality Management

- 21 Work Study and Method Study

- 22 Supply Chain Management

- 23 Enterprise Resource Planning

- 24 Miscellaneous Topics

- 25 Production Management Methods

- 26 Theory of Constraints

- 27 Conclusion

- Index