This is a test

- 238 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Industrial Approaches in Vibration-Based Condition Monitoring

Book details

Book preview

Table of contents

Citations

About This Book

Vibration-based condition monitoring (VCM) is a well-accepted approach in industries for early detection of any defect, thereby triggering the maintenance process and ultimately reducing overheads and plant downtime. A number of vibration instruments, data analyzer and related hardware and software codes are developed to meet the industry requirements. This book aims to address issues faced by VCM professionals, such as frequency range estimation for vibration measurements, sensors, data collection and data analyzer including related parameters which are explained through step-by-step approaches. Each chapter is written in the tutorial style with experimental and/or industrial examples for clear understanding.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Industrial Approaches in Vibration-Based Condition Monitoring by Jyoti Kumar Sinha in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Mechanics. We have over one million books available in our catalogue for you to explore.

Information

1 | Introduction |

1.1 CONDITION MONITORING

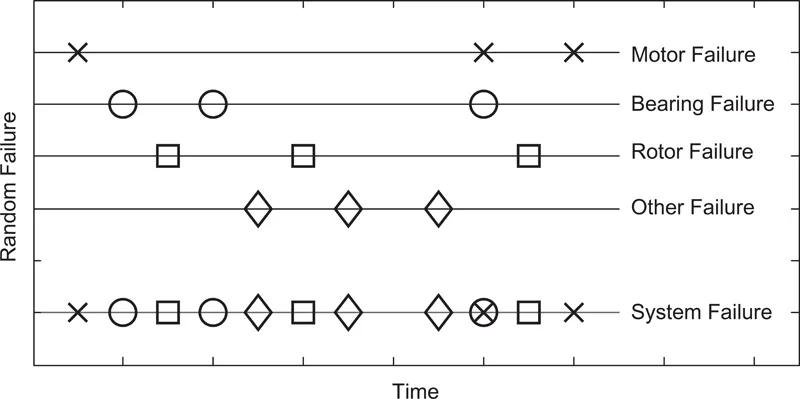

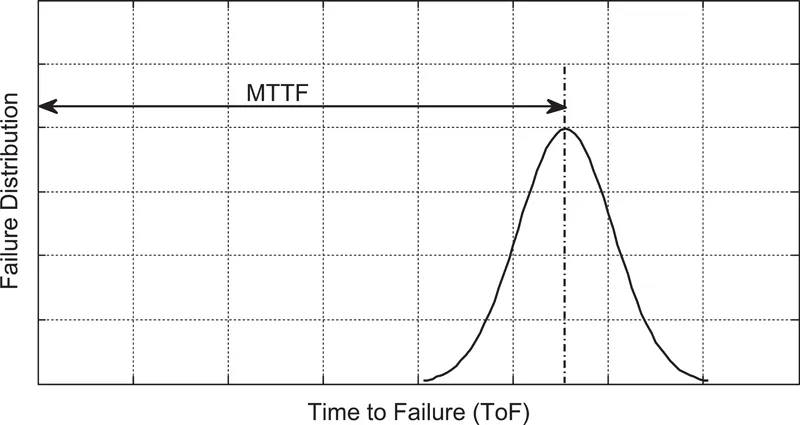

It is well known that machines keep on developing faults (or defects) during their normal operation that often lead to failures if not monitored regularly. The failures are generally random and may occur in different components of any machines. Figure 1.1 shows random failures of a motor, bearing, rotor and other components in a machine. The probability of failure distribution for a machine can generally be represented by Gaussian distribution as shown in Figure 1.2. The mean-time-to-failure (MTTF) may be different for many identical machines. This simply means that there are many failures before the MTTF. It is also difficult to predict which component is going to fail next based on statistical data.

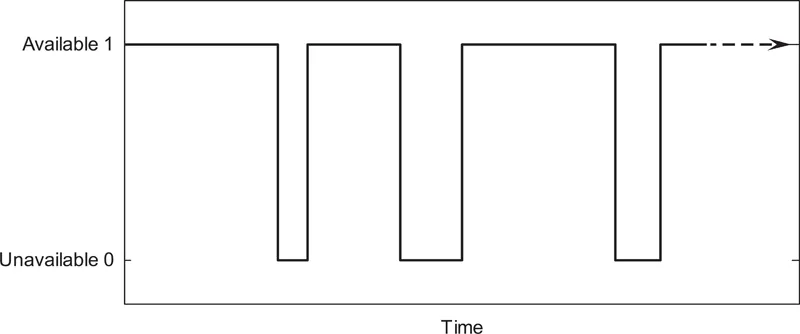

The impact of failures of any machine or any unit within an industry depends upon its functional requirements. The failure of any critical machines/equipment may impact plant safety, production loss and more maintenance overhead. The random up-and-down time of any critical machines or any plant (Figure 1.3) may not be acceptable. Hence a more reliable approach is needed that can monitor the health condition during the plant operation and predict the defect (or fault), if any, before failure. This process is known as “Condition Monitoring (CM).”

1.2 CONDITION MONITORING TECHNIQUES

There are several non-destructive test (NDT) techniques are available and currently used in industries to meet the need of the CM. A few of the commonly used techniques are listed here.

1. Monitoring of machine and process parameters: It is often found to be the best indicator of machine health condition and its performance e.g., car dashboard providing information of engine revolution per minute, coolant level and temperature, parking break, engine condition, etc.

2. Temperature monitoring: The temperature monitoring is also useful in many cases to identify the defect such as mechanical rubbing in machines, defects in anti-friction bearings, leak in pipe, etc.

A temperature sensor can measure the temperature at a point of machine and structure. Hence more number of sensors is required to map the temperature distribution of a machine or structural surface. Thermography overcomes this limitation. This works on the infrared energy emission concept to measure the object surface temperature. The thermography camera is now popular and commonly used to monitor the machines and structure surface temperature remotely. It can identify the “hot spot” quickly and useful for several applications. The simplest example is identifying the hot spot in the main electrical circuit board of any building (shopping mall, hospital, plant, etc.) due to looseness in electric circuits.

3. Lubricant monitoring: The lubricant is used in the several machines. The lubricant condition keeps on deteriorating during its use which may impact the machine performance; therefore its regular mentoring is required so that it can be replaced in time. The following two monitoring processes are useful.

Lubricant properties – This is mainly related the monitoring of the concentration of additives and other properties of the lubricant.

Debris analysis – It is measure of number of metal particles and their sizes in the lubricant. The wear particles from the rubbing surface in the lubricant can be used to identify the defects in bearings, gearboxes, etc.

4. Leak detection monitoring: The leak detection in the pipe conveying fluid is essential for several applications. Pressure sensor, acoustics wave reflection, etc. can be to detection the leak. The ultrasound technique may be useful but it is a time-consuming process for long pipeline. The tracer gas technique can also be used at certain time interval.

5. Noise monitoring: Microphones or hydrophones are used for this purpose depending upon the surrounding medium. This is found to be useful for monitoring machines, damage in pipelines, etc.

6. Acoustic emission monitoring: It is observed that the occurrence of crack, propagation of damage in any structures, bearing defects, etc. generally release energy at very high frequency range (more than 70–80 kHz). Such signals can be picked up by the acoustic emission sensor; however the detection process is heavily dependent on the resonance frequency of the sensor. Therefore an appropriate selection of the sensor is essential for any particular application.

7. Vibration monitoring: Vibration monitoring is widely used in the CM of machines and structures in industries. The vibration can detects the change in any objects (machines or structures) that can be explained through the mechanical vibration theory; hence, the vibration measurements, tests and analysis are already popular tools for several applications such as design qualification, design optimization, condition monitoring of structures and machines, vibration insolation and control, etc.

Vibration measurements and data analysis related to machines are mainly discussed in this book, but the same instruments and concepts can be applied to any structural components.

1.3 CONDITION-BASED MAINTENANCE

A range of maintenance strategies is available to the maintenance manager. They are:

1. Breakdown Maintenance (BM) or Run to failure: Here the maintenance activity is carried out after the failure of items. It is good to select those items of the plant that ...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- Preface

- Author

- Chapter 1 Introduction

- Chapter 2 Simple Vibration Theoretical Concept

- Chapter 3 Vibration-Based Condition Monitoring and Fault Diagnosis: Step-by-Step Approach

- Chapter 4 Vibration Instruments and Measurement Steps

- Chapter 5 Signal Processing

- Chapter 6 Vibration Data Presentation Formats

- Chapter 7 Vibration Monitoring, Trending Analysis and Fault Detection

- Chapter 8 Experimental Modal Analysis

- Chapter 9 Operational Deflection Shape (ODS)

- Chapter 10 Shaft Torsional Vibration Measurement

- Chapter 11 Selection of Transducers and Data Analyzer for a Machine

- Chapter 12 Future Trend in VCM

- Index