eBook - ePub

Biomass and Carbon Fuels in Metallurgy

This is a test

- 292 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Biomass and Carbon Fuels in Metallurgy

Book details

Book preview

Table of contents

Citations

About This Book

Biomass and Carbon Fuels in Metallurgy presents contemporary and new insights into the use of carbonaceous (Biomass) fuels in the metallurgical sector. The authors describe application of these fuels in different technological processes to produce pig iron, steel and ferroalloys. Emphasis is placed on biomass and its metallurgical utilization. Coverage includes the specification of fuels, their classification and the characteristics of their basic properties. The use of carbonaceous fuels in the production of various kinds of agglomerates (ferriferous, manganese and metalized) is also covered.

Key Features:

-

- Provides a comprehensive view of carbonaceous fuels in various metallurgy processes

-

- Details experiments conducted on the use of traditional and alternative (biomass) carbonaceous fuels for the production of agglomerates.

-

- Demonstrates that the energy potential of biomass can also be successfully used in pyrometallurgical processes

-

- Describes applications of biomass-based fuels in different technological processes for the production of pig iron, steel and ferroalloys.

-

- Coverage includes the specification of fuels, their classification and the characteristics of their basic properties.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Biomass and Carbon Fuels in Metallurgy by Jaroslav Legemza, Mária Fröhlichová, Róbert Findorák in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Chemistry. We have over one million books available in our catalogue for you to explore.

1. Introduction to the field

The publication “Biomass and Carbon Fuels in Metallurgy” brings contemporary but also new insights into the use of carbonaceous fuels in the metallurgical sector. These fuels are deficient raw materials nowadays. Therefore, it is necessary to find their optimal use. Dwindling traditional fossil fuels and the dynamic growth of the world population are critical factors in our society concerning maintaining the development of industrial production and ensuring energy security. Increasing demand of countries for sufficient energy supply and associated threat to the biosphere will characterise the environment in which we will live in the decades to come. The energy policy of the European Union brought to the fore environmental issues and the issue of decreasing the dependence on imported energy, resulting in the requirement for the maximum possible use of renewable energy sources. Biomass is a very significant renewable energy sources, which is used not only in the energy industry but also in technologies of ferrous metallurgy. The energy potential of biomass can be successfully utilised in the pyrometallurgical processes, which has been partially predicted and confirmed by existing research and studies.

The publication “Biomass and Carbon Fuels in Metallurgy” is mainly oriented on the use of carbonaceous (traditional and alternative) fuels in the metallurgical sector. It describes the application use of these fuels in different technological processes for the production of pig iron, steel and ferroalloys. In this publication, the emphasis is placed on the biomass and its metallurgical utilisation.

The introductory part of the publication “Biomass and Carbon Fuels in Metallurgy” is focused on the specification of fuels, their classification and the characteristics of their basic properties.

Another section is dedicated to the utilisation of traditional carbonaceous fuels in the production of agglomerates, pig iron, steel and ferroalloys. An important part focuses on the use of these carbonaceous fuels in the production of various kinds of agglomerates (ferriferous, manganese and metallised).

A significant part of the publication is oriented on alternative fuels – particularly biomass and its utilisation for metallurgical purposes. It describes characteristics of biomass, techniques of its treatment and the possibilities of its use in the production of charge for blast furnaces, pig iron, steel and ferro-alloys – with emphasis on the use of biomass for the production of ferriferous agglomerates.

The final part of the publication “Biomass and Carbon Fuels in Metallurgy” is focused on defining the relationship between biomass and the environment and the prediction of potential new alternative fuels of the future.

The authors of “Biomass and Carbon Fuels in Metallurgy” have long-term experience in the field of production of various kinds of agglomerates. Recently, they have also been working in the area of biomass use as a substitute for coke powder in the production of the ferriferous agglomerate. Since this area is still rather unexplored and the significant advantages and disadvantages of biomass utilisation have not been fully defined, the authors decided to offer their experience with the use of carbonaceous fuels in metallurgy both to the expert community and the general public.

Biomass represents great potential for the metallurgical industry – although its use and utilisation for specific technological fields of metallurgy are limited. Biomass should be perceived in the context of the relationship between human society, nature, and the production cycle, where its representation should be in accordance with ecological and economic needs of a manufacturing enterprise. By effective use of even a small amount of wood or plant matter from secondary materials in metallurgy, we gain not only the benefit of saving a certain amount of conventional fossil fuels, but we mainly achieve the potential and experience in operating the metallurgical production technologies using alternative fuels. The entire development of metallurgical production technologies using alternative fuels would not be possible without sufficient human resources. It is therefore important to ensure the training of experts for future work in this area. A good theoretical basis is the prerequisite for the education of these professionals. The publication “Biomass and Carbon Fuels in Metallurgy” is thus intended both for lecturers and students of technical universities, researchers, experts from practice, and also for the general public interested in the issue of carbonaceous fuels and their alternatives and implementation in metallurgy. The publication can be used not only in metallurgy but also in the fields of energy, ecology and other technical scientific disciplines.

2. Fossil fuels and renewable energy sources

Energy

Energy is the basis of all processes that take place around us and is the most critical factor influencing the development of society. Energy is a phenomenon without which life is inconceivable today. Without energy, we could not use most of the production facilities and household appliances, set vehicles in motion and we would not have heat and light. If we look at today’s world through the prism of the main and priority areas on which we should focus, then there is certainly a question of ensuring low-cost and sustainable forms of energy. Yes, it is necessary to find, transform and utilise these forms of energy, but it is necessary to do it ecologically. So, let us try to extend the phenomenon of energy into the phrase “energy and environment”.

How has the humankind changed in the last 100 years? How have production technologies changed during that time? How has the range of manufactured products changed over that period? How has the people’s view of the need for energy and its use at their work and in their daily life changed? And how has our environment changed in the context of energy production and subsequent manufacturing activity? How long will the basic fossil fuels last? Will we be able to replace these fuels completely? These are the questions we could answer at length, but also with a simple and short sentence: “We live in dynamic times – with high energy consumption”. Those who see the threat of basic energy sources depletion and climate change associated with greenhouse gas emissions know the meaning and the importance of finding new forms of energy. Some traditional energy sources are being gradually consumed and are increasingly expensive. Therefore, we have searched for alternative forms of energy sources for decades. Maybe it is appropriate to ask a question, whether it would not be better to find and develop such technologies and products that would require minimum energy instead of searching for alternative forms of energy sources. Or to implement effective energy saving, which represents the cheapest “source of energy”.

Energy sources

Non-renewable and renewable energy sources are used in various technological processes in the production of the required forms of energy. The non-renewable energy sources include mainly fossil fuels based on coal and hydrocarbons. Fossil fuels may be present in solid (e.g. coal), liquid (e.g. petroleum products) or gaseous (e.g. natural gas) form. The non-renewable energy sources also include nuclear energy, Fig. 1.

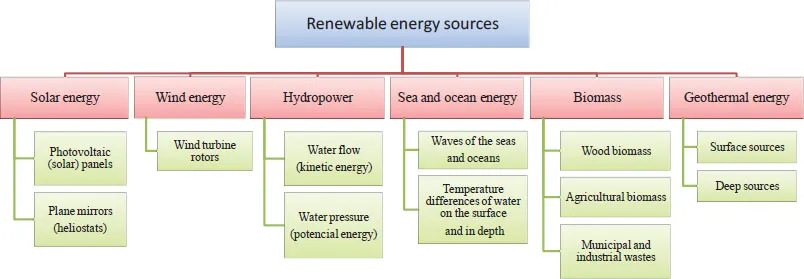

Currently, the most important renewable energy sources are hydropower, biomass and solar energy, Fig. 2 [1, 2, 3].

Fig. 3 shows a graphical view of the energy consumption according to the energy sources used in the world. Apparently, the consumption of traditional fossil fuels was considerably predominant in the last 40 years. Fossil fuels are the predominant source of energy, and they account for total world energy consumption of around 87 % (in 2013). Hydropower has the highest representation among the renewable energy sources. So far, biomass has only a minimum share in the total energy production and consumption.

The genesis of fossil fuels

The basic solid fossil fuels include peat, brown coal, lignite, bituminous coal (Fig. 4) and anthracite (Fig. 5). Coke is the special type of fossil fuel (Fig. 6). Coal, coke, petroleum products and natural gas represent the highest quality sources of fossil fuels and are among the most important sources of energy that are currently used.

In terms of raw material energy, there is a significant potential in so-called unconventional fossil fuels like petroleum and coal shale, biomethane, heavy oil sands, asphaltenes and the like. [4, 5, 6, 7].

Let us look in more detail at the processes of the genesis of individual fossil fuels. Peat is formed from plant residues on the surface of Earth, while the coal formation takes place in the depth of Earth. Peat is the predecessor of coal, as it is the first step of converting plant matter into coal. In the long term, peat is primarily formed by biochemical processes, whereas coal is formed by geochemical and physical processes [5]. Peat is divided by prevailing botanical composition into moss and wood, and by soil admixture into pure and natural. Peat has high water content (65 to 85 %). Therefore, it is processed before use by pressing and drying to the water content below 25 %. Coal is a non-renewable fossil fuel, which was created by means of natural geological processes from plant residues. They were most commonly accumulated in swamps, lakes or seas. Coal is a brown or black combustible rock composed of heterogeneous components with different physical and chemical characteristics. Coal retains the information of plant material and the environment in which the plants grew and accumulated [8, 9]. Most of the world’s coal reserves began to form 300–400 million years ago by anaerobic biochemical reactions at high temperature and pressure acting for a long time. Temperature and pressure are fac...

Table of contents

- Cover

- Title Page

- Copyright Page

- Foreword

- Table of Contents

- Used abbreviations and important explanations

- 1. Introduction to the field

- 2. Fossil fuels and renewable energy sources

- 3. The role of fuels in metallurgy

- 4. CO2 emissions and metallurgical technologies

- 5. Distribution of fuels and their reserves

- 6. Carbonaceous fuels, their properties and testing

- 7. Use of traditional fuels in the production of agglomerates

- 8. Use of conventional carbonaceous fuels in the pig iron production

- 9. Use of traditional carbonaceous fuels in the production of steel and ferroalloys

- 10. Traditional carbon fuels and the environment

- 11. Alternative fuels

- 12. Utilization of biomass in the production of Fe agglomerates

- 13. Use of alternative fuels in the production of pig iron

- 14. Use of alternative fuels in the production of steel and ferroalloys

- 15. Alternative fuels and environment

- 16. Alternative fuels of the future

- 17. Conclusion

- List of figures

- List of tables

- References