- 372 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Powdered Detergents

About this book

Facilitating the development of important processes that yield increased detersive performance from smaller dosages, this work examines up-to-date and emerging process and chemical technologies used in the formulation of compact powdered detergents. It provides a survey of technological developments fundamental to powder compaction, such as the replacement of traditional phosphate builders and the introduction of insoluble zeolites as particle process aids.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Powdered Detergents

| I. | Introduction |

| II. | Historical Perspectives |

A. Detergent formulation | |

B. Detergent processing | |

| III. | Conversion to Compact Powders |

| IV. | Impact of Compaction on Process and Chemical Technologies |

A. General trends | |

B. Process technology changes | |

C. Chemical technology changes | |

D. Compact powder compositions | |

| V. | Future Trends |

| References |

I. INTRODUCTION

The laundry market is hardly the place one expects to see revolutionary change. For decades laundry detergents were typified by low-density synthetic powders containing a relatively limited number of ingredients, i.e., alkyl benzene sulfonate and alkyl sulfate surfactants, phosphate builders, sodium carbonate and silicate for alkalinity and machine protection, and sodium sulfate filler. The makeup of the market began to change in the mid-1960s when, under environmental pressure, the industry initiated a gradual transition from phosphate- to zeolite-based builder systems. Multiplication of product form began in the early 1970s with the introduction of liquid detergents. Yet through the mid-1980s the basic product forms with their high-volume dosages and bulky, giant-sized packaging remained largely unchanged.

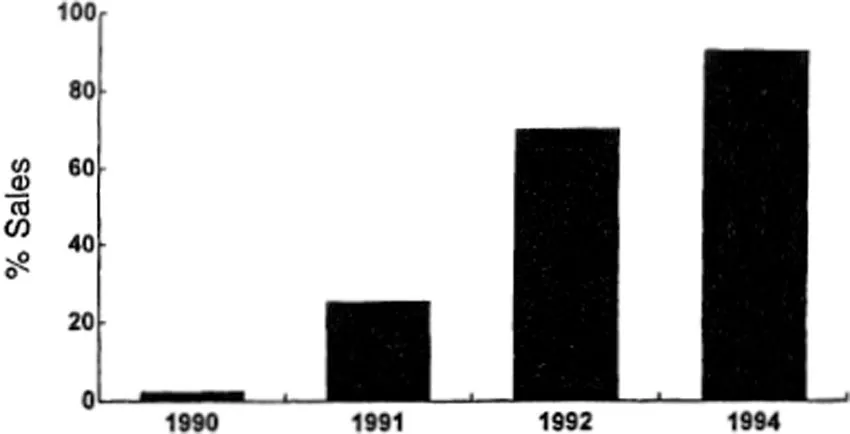

Beginning in the late 1980s, however, a revolution gripped the detergent industry with the introduction and rapid market expansion of compact powders. The revolution started in Japan in 1987 when the Kao Corporation introduced Attack, a compact high-density powder product. Within the first year of conversion compact powders captured 60% of the Japanese laundry market ultimately growing to over 90% [1]. By early 1989 compact powders began to appear in Europe and late that year they expanded into the United States [2]. From 1990 to 1994, compact, concentrated powders grew from 2% to over 90% of the powder market in the United States [3] (Fig. 1). Today compacts have largely supplanted the traditional low-density powder products in the United States, Europe, and Japan and are spreading to developing markets in Latin America, Eastern Europe, Asia, and the Pacific region.

What exactly is a “compact powder?” Compared to traditional powders, compacts are characterized by

1. Higher bulk densities. Whereas traditional powders have bulk densities ranging from 200 to about 500 g/L, compact densities typically range from 600 to 900 g/L and higher, although there are some regional exceptions, e.g., the compact powders currently found in the Canadian market have densities on the order of 400 g/L. This generally results in the same amount of washing powder delivered in a much smaller volume of product.

2. Higher surfactant levels. Surfactant levels in low-density products usually do not exceed 20 wt%. Compact powders typically have surfactant levels of 25 wt% or more.

3. Lower dosages. In North America, recommended dosages for low-density powders range from 85 to 100 grams per wash load. Current compact dosages range from about 60 to 90 grams per load. In terms of volume of product used per load, dosages in the United States have gone from 1 cup to 1/2 cup or less. In 1986, a typical European powder detergent dosage was ~200 grams per wash load. Today compacts with recommended dosages of ~70 grams per load are on the market.

FIG. 1 Growth of compact detergents in the U.S. market from 1990 to 1994.

The move to compact powders has fueled significant change in both the process of detergent manufacture and the chemical technologies used in detergent formulation. Manufacturers are moving away from the standard spray tower operation that has been the hallmark of powder detergent production for almost 50 years. The demand for ever-increasing product densities has forced manufacturers to alternate processes like agglomeration. The drive to compaction has put formulation space at a premium requiring increased reliance on, and innovation of, space-efficient technologies like enzymes. The purpose of this book is to capture the trends in process and chemical technology that continue to drive compaction and densifìcation of powder detergents.

II. HISTORICAL PERSPECTIVES

A. Detergent Formulation

Prior to World War I, laundry products consisted principally of sodium- or potassium-neutralized fatty acid soaps. The first synthetic detergents, short chain alkyl naphthalene sulfonates, were produced in Germany during World War II as replacement for the then-scarce animal fats traditionally used in the production of soaps. Long chain alkyl aryl sulfonates were introduced as detergents in the 1930s and by 1945 had become the main surfactant component of synthetic laundry detergents [4]. The first built synthetic detergent, using sodium diphosphate as the builder, was introduced in the United States in 1947 [5].

The surfactants used in early synthetic detergents were prepared by reacting benzene with propylene tetramer to form the alkyl aryl group, which was then sulfonated. These materials, the so-called hard ABSs, were highly branched and nonbiodegradable. Over time they accumulated in the environment to such an extent that foaming resulted in some sewage treatment plants and waterways. In 1965 the U.S. detergent industry voluntarily withdrew hard ABSs from the market, replacing them with biodegradable linear chain analogs [5].

At the time of conversion to compacts the most widely used surfactants in synthetic powder detergents were the anionics; linear alkyl aryl sulfonates, or LASs, and long chain fatty alcohol sulfates, or ASs; and, to a lesser extent, long chain fatty acids, and the nonionic alkyl ethoxylates.

In the mid-1960s, concern arose over the environmental fate of complex phosphates due to their implication in eutrophication of waterways. Since then, the detergent industry has devoted considerable energy to finding cost-effective replacements. The introduction of ion exchange materials, zeolites, as detergent builders in the mid-1970s led to a gradual movement away from phosphate technology. With the recent changes in formulation and manufacturing processes precipitated by the transition to compact detergents, the major U.S. manufacturers took the opportunity to formulate out of phosphate altogether. Importantly, this was achieved without compromising performance or consumer value. Today the conversion of the U.S. detergent market to nil-phosphate formulas is virtually complete, 32% of European powders are zeolite-based [1], Canada is about 50% converted, whereas Latin America and many of the Pacific region geographies remain largely phosphate.

However, the move to nil-phosphate builder systems increased the overall complexity of powdered detergents. In addition to binding hardness ions, phosphates provide a number of other functions that are critical to efficient soil removal and cleaning. These include soil peptization or breakup, soil dispersion, suspension, and pH buffering. Removing phosphate from detergent formulas required manufacturers to identify other actives that could fulfill its multifunctional role. Today nil-phosphate powders contain zeolites and/or layered silicates for hardness control, polycarboxylate polymers for soil suspension, citric acid for soil peptization and dispersion as well as pH control, and carbonate for calcium control and buffering.

Table 1 shows a typical composition for the type of low-density, nil-phosphate powder product available on the market in the mid-1980s.

B. Detergent Processing

The principal methods of producing low density powders are as follows [5]:

Adsorption of liquid ingredients...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Preface

- Table of Contents

- Contributors

- 1. Powdered Detergents

- 2. Compact Powdered Detergent Process Technologies

- 3. Builders: The Backbone of Powdered Detergents

- 4. Polymeric Dispersants in Powdered Laundry Detergents

- 5. Enzymes

- 6. Bleach Systems for Compact Detergent Granules

- 7. Soil Release Agents in Powdered Detergents

- 8. Surfactant Requirements for Compact Powder Detergents

- 9. Detergency Mechanisms

- 10. Overview of Regulation and Environmental Issues Affecting Laundry Detergents

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Powdered Detergents by Michael Showell in PDF and/or ePUB format, as well as other popular books in Naturwissenschaften & Chemie. We have over one million books available in our catalogue for you to explore.