- 240 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Primer on Composite Materials Analysis (revised)

About this book

This outstanding reference presents an up-to-date account of investigations during the last 10 years in the area of injection and compression molding of polymers.Injection and Compression Molding Fundamentals considers simulation andexperimentation of flow dynamics in the cavity and delivery system . . . discussesrheology and viscoelastic modeling ... clarifies fiber orientation ... delineates residualstresses and processing-property relationships in molded parts ... and details computeraideddesign and manufacture of the mold.In addition, the book highlights specific features and problems related to the molding ofthermoplastics, rubbers, and thermosets ... and reveals the current status of the sciencebasedtechnology related to injection and compression molding.The most detailed and authoritative reference of its type, Injection and CompressionMolding Fundamentals is an invaluable resource for plastics, mechanical, andchemical engineers; colloid, oil, and color chemists; polymer engineers and scientists;mold designers and manufacturers; rheologists; and materials scientists. The book willalso be of value for use in graduate-level courses in plastics, mechanical, chemical, andpolymer engineering, and in short courses and seminars offered by professional societies.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

CHAPTER 1

Introduction

1.1 THE NATURE AND SCOPE OF COMPOSITE MATERIALS

We shall be primarily concerned with a class of complex materials, composites, in which nonwoven fibers are deliberately oriented in a matrix in such a way as to increase its structural efficiency. Current developments are pointed toward combinations of unusually strong, high modulus fibers and organic, ceramic, or metal matrices. Such materials promise to be far more efficient than any structural materials known previously, and they promise to extend the temperature-performance spectrum into regions unattainable only a few years ago.

Because of the variety of combinations and arrangements of fibers and matrices combined with the concept of lamination, designers have today greatly increased opportunities for tailoring structures and/or materials to meet systems of forces and changing environments. Achieving this goal necessitates new techniques in design and manufacture and the compilation of vast amounts of information on the properties of a whole new family of materials.

This situation exists today despite the fact that the concept of fiber reinforcement was known and employed in ancient times. As an example, straw was used by the Israelites in the manufacture of bricks in 1200 B.C. It was realized at that time that the addition of chopped straw or other fibrous vegetable matter was an improvement from several points of view. It assisted the evaporation of moisture from the interior and helped to distribute more evenly the cracks that were formed, thereby increasing the “structural performance” of the mud brick. A short time thereafter, the Mongol bow was constructed of a composite of animal tendons, wood, and silk bonded together with an adhesive. Still later, laminated structure appeared in the form of Damascus gun barrels and Japanese ceremonial swords.

The first “high performance” composite material is as old as man himself: it is the human body—the bones and muscle tissue—that is a multidirectional fibrous laminate. The most widely used high performance composite of commercial importance today, and the forerunner of modem composite material science, is the pneumatic tire. In fact, it is rather interesting to note that modern technology is, in many ways, repeating the practices of the past. Not only are we now using fibers for strength and stiffness reinforcement but also modern fabricators are employing resistant heating of the reinforcements themselves to aid in the rapid curing of composites without inducing high internal cure stresses. Shades of the Israelites conducting moisture from mud blocks with straw.

In this monograph an elementary but detailed development of the new design procedures for modern fibrous composites shall be developed. Our emphasis is on stiffness properties and/or calculations. In order that we might illustrate an elementary design procedure, it will also be necessary for us to discuss briefly a failure or strength criterion. This illustration is accomplished by adopting the simplest criterion possible, solely for the purpose of analytical ease.

1.2 COMPOSITE MATERIALS TERMINOLOGY

The two terms that describe the engineering materials with which the materials scientist, analyst, or designer normally works (i.e., metals, thermosetting, or thermoplastic organic polymers) are homogeneous and isotropic. In contrast, a laminated composite material may be described by any of the following terms: homogeneous orthotropic; homogeneous anisotropic; heterogeneous orthotropic; heterogeneous anisotropic; and quasiisotropic. The materials scientist, analyst, and designer must become familiar with these terms and with the concepts on which they are based in order to become proficient in the use of composites and to be able to communicate regarding composite materials. These terms and other terms pertinent to composites will be defined in this section.

Generally speaking, a composite material is a material with several distinct phases present. Normally, the composite consists of a reinforcing material (fiber, whisker) supported in a binder or matrix material. The reinforcing material is normally the load carrying medium in the material, and the matrix serves as a carrier, protector, and load splicing medium around the reinforcement.

One of the first applications of composite materials occurred in the aircraft industry when cloth fiberglass laminates were utilized for secondary structural applications such as radomes. Composite materials were first used in primary structural applications when filament-wound (glass) pressure vessels were developed for the Polaris missile engines. The birth of so-called advanced composites began with the fabrication of boron filaments in the early 1960s. These continuous filaments are considerably stiffer and stronger than the glass filaments that preceded them; hence, the name advanced composite materials evolved.

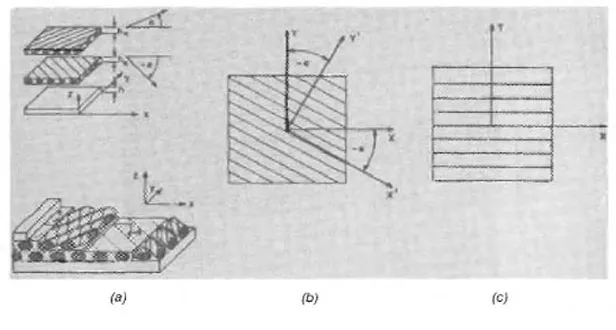

The term filamentary composites is often used to differentiate between continuous filament composites and short filament or whisker reinforced composites. A filamentary composite is normally made up of several plies or laminae. One lamina of a filamentary composite consists of one row of parallel filaments surrounded by the matrix, Figure 1.1. The lamina are stacked with various orientations of the filament direction between lamina to obtain a laminate that has the desired stiffness or strength properties.

As previously stated, the two terms that describe the engineering materials (metals) with which the aircraft stress analyst or designer normally works are homogeneous and isotropic. The term homogeneous means uniform; that is, as one moves from point to point in the material, the material properties (stiffness, thermal conductivity, thermal coefficient of expansion, etc.) remain constant. The material properties are not a function of position in the material. The term isotropic indicates that the material properties at a point in the body are not a function of orientation. In other words, the material properties remain constant regardless of the reference coordinate system at a point. As a result, the material properties are constant in any plane which passes through a point in the material. Therefore, for an isotropic material, all planes which pass through a point in the material are planes of material property symmetry.

FIGURE 1.1a, b, c. Illustration of an orthotropic material in its laminated and lamina forms.

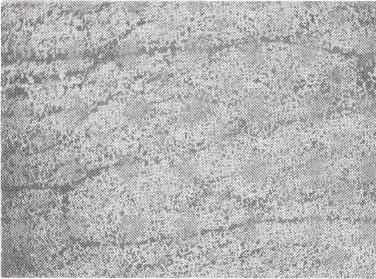

FIGURE 1.1d Photomicrograph of a lamina of a graphite/epoxy material (100 ×).

In an orthotropic material, only three mutually perpendicular planes of material property symmetry may be passed through a point. For an anisotropic material, there are no planes of material property symmetry which pass through a point. Therefore, for an orthotropic and for an anisotropic material, one would expect the material constants at a point to change as one rotated the coordinate system at the point. Isotropic and orthotropic materials are specialized classes of materials which have a higher degree of symmetry than anisotropic materials.

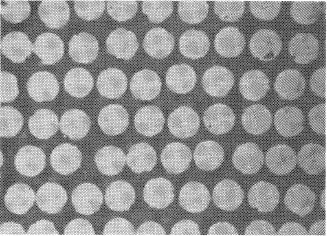

FIGURE 1.1e Enlarged photomicrograph of a fiber bonded in a graphite/epoxy material (500 ×).

FIGURE 1.1f Boron laminate (100 ×).

A material may be isotropic, orthotropic, or anisotropic and either be homogeneous or heterogeneous. If a material is homogeneous, the material properties do not change from point to point in the body although they may change with a coordinate rotation at the points (orthotropic or anisotropic). As long as the material properties are the same for the same coordinate position from point to point in a body, the material is homogeneous; otherwise, the material is said to be heterogeneous.

By referring to Figure 1.1, it is evident that the individual ply or lamina of a filamentary composite has three mutually perpendicular planes of symmetry for the material constants. The intersection of the three planes forms the axes of the coordinate system shown. Since the lamina has three perpendicular planes of symmetiy, it can be considered to be an orthotropic material on the macroscopic level. Also, the lamina may be considered homogeneous on the macro scale. The set of axes that are parallel and perpendicular to the filament direction are termed the lamina principal axes.

In the literature on composite materials, one often encounters the term constitutive equation—a term borrowed from the science of rheology. The term constitutive refers to the stress-strain or Hooke’s law relationships for a material because the stress-strain relations actually describe the mechanical constitution of the material.

The term quasi-isotropic is used quite often in the literature on composite material. The term is used to describe a particular type of laminate—a laminate that has essentially isotropic stiffnesses and perhaps strength. The simplest quasi-isotropic laminate is a three-ply laminate with a 0°, ±60° orientation. The next possible quasi-isotropic laminate is the four-ply 0°, ±45°, 90° laminate. Of course, the more plies in the laminate, the less is the angle between the principal axes of each lamina; hence, the laminate will better simulate an isotropic condition.

CHAPTER 2

Properties of an Orthotropic Lamina

In this chapter, the mechanics governing the behavior of the individual lamina or ply of a laminated composite will be developed. The discussion will be generalized to include laminae that are isotropic, orthotropic, or anisotropic in n...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Acknowledgement

- Preface to the Second Edition

- Chapter 1. Introduction

- Chapter 2. Properties of an Orthotropic Lamina

- Chapter 3. Laminated Composites

- Chapter 4. Strength of Laminated Composites

- Chapter 5. Analysis of Composite Structures

- Chapter 6. Structure Property Relationships for Composite Materials

- Chapter 7. Characterization and Behavior of Structural Composites

- Appendix A: Matrices and Tensors

- Appendix B: Equilibrium Equations for Plates

- Appendix C: Trigonometric Functions for Laminated Composites

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Primer on Composite Materials Analysis (revised) by John C. Halpin in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.