eBook - ePub

Encyclopedia of Chemical Processing and Design

Volume 45 - Project Progress Management to Pumps

This is a test

- 568 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Encyclopedia of Chemical Processing and Design

Volume 45 - Project Progress Management to Pumps

Book details

Book preview

Table of contents

Citations

About This Book

""Written by engineers for engineers (with over 150 International Editorial Advisory Board members), this highly lauded resource provides up-to-the-minute information on the chemical processes, methods, practices, products, and standards in the chemical, and related, industries.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Encyclopedia of Chemical Processing and Design by John J. McKetta Jr in PDF and/or ePUB format, as well as other popular books in Education & Education Teaching Methods. We have over one million books available in our catalogue for you to explore.

Information

Pumps

Contents

1. Introduction

2. Liquid Conditions

3. Corrosion

4. System Characteristics

5. Pump Class Selection

6. Centrifugal Pumps

7. Rotary Pumps

8. Reciprocating Pumps

9. Metering Pumps

10. Utility Pumps

11. Seals

12. Couplings

13. Baseplates

14. Procurement

15. Installation

16. Operation

17. Maintenance

Symbols

1. Introduction

Pumping in the chemical process industry involves the bulk movement of process liquids, the precise injection of reactants, and the provision and dissipation of energy. For convenience, these three functions are referred to as process, metering, and utility. While utility does not involve the handling of process chemicals, there will be no processing without it, so its inclusion is justified.

Pumping is the so-called “heart” of chemical processing, and it’s a good analogy. Successful pumping is thus of fundamental importance; achieving it involves getting all the following “right”:

1. Conditions of service

2. Pumping specification

3. Procurement

4. Installation

5. Operation

6. Maintenance

Not getting any one of these “right” can cripple a process. Generally, though, mistakes in the last four can be corrected, albeit at great expense. But if the first two are not “right,” if the basics are not sound, all subsequent corrections will be “Band-Aids.”

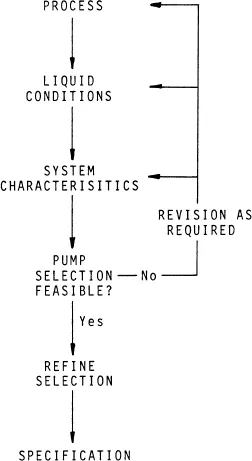

Because developing a sound pump specification is so important, it is the focus of this section. Figure 1.1 shows the basic sequence for doing this, which this volume follows. Note, also, that iteration is an inherent part of this sequence.

The pump types reviewed are centrifugal, rotary, and reciprocating. For each type the review covers basic characteristics, specific configurations and their uses, then available materials of construction, all with a view to chemical process service. For clarity, specific information on metering and utility pumps is given in Chapters 9 and 10, respectively.

The size of this volume is limited, thus an exhaustive treatment is not possible. Instead, the material seeks to highlight the fundamental, the novel, and the usually troublesome, thereby supplementing other related material. For greater detail on pumps in general, the reader is referred to the Pump Handbook [1.1], The Chemical Engineering Guide to Pumps [1.2], Centrifugal Pumps [1.3], and Reciprocating Pumps [1.4]. A recent publication, Process Pump Selection—A Systems Approach [1.5], adds notably to the “art” of pump selection (in metric units). Throughout the volume, references on specific topics are cited to enable further reading.

FIG. 1.1 Process for developing a sound pump specification.

References

1.1. I. J. Karassik et al. (eds.), Pump Handbook, 2nd ed., McGraw-Hill, New York, 1986.

1.2. K. McLaughton (ed.), The Chemical Engineering Guide to Pumps, McGraw-Hill, New York, 1984.

1.3. I. J. Karassik and R. Carter, Centrifugal Pumps, McGraw-Hill, New York, 1960.

1.4. T. L. Henshaw, Reciprocating Pumps, Van Nostrand Reinhold, New York, 1987.

1.5. J. Davidson (ed.), Process Pump Selection—A Systems Approach, The Institution of Mechanical Engineers, Suffolk, U.K., 1986.

2. Liquid Conditions

Chemical process pumping involves the handling of liquids that are corrosive or toxic or both. This requirement distinguishes the service from general pumping and has a major bearing on materials of construction, internal mechanical construction, and the type of seal necessary.

Because the nature of the liquid to be pumped has such a bearing on pump construction, its precise determination is an essential first step in any pumping application. Not doing this with sufficient precision is a prime cause of premature failure in chemical pumps.

2.1. Properties

Liquid properties influence the type of pump and its mechanical construction. Those needed for pump selection are:

Specific gravity (SG) or relative density (RD)

Vapor pressure

Viscosity

Rheological characteristic (if other than Newtonian)

Specific heat, though not often quoted, is useful, particularly when the application has minimal net positive section head (NPSH) available.

Liquid properties are usually specified at the pumping temperature or over the expected temperature range, if that is the case.

2.2. Temperature

Liquid properties and corrosiveness vary markedly with temperature, thus the precise temperature is important. General terms such as “cold,” “hot,” or “ambient” do not provide sufficient information. An ideal specification gives the expected temperature range and the normal operating temperature.

2.3. Constituents

Most liquids pumped are solutions of multiple constituents. To help insure the most appropriate materials are used for the pump, it is necessary to know the liquid’s constituents and their concentration. In this connection it is vital that all constituents, major and trace, be identified and that their concentration be given in specific units.

Trace constituents, particularly halogens, halides, or compounds of hydrogen, can render a nominally suitable material entirely unsuitable. Examples are the effect of fluorides on high silicon iron (cited by Birk and Peacock in Ref. 1.1) and of hydrogen sulfide on a variety of materials (see NACE [2.1]).

Concentration needs to be stated specifically to avoid varying interpretations of terms such as “dilute” and “concentrated.” Similar treatment is necessary for trace constituents because their effect can vary markedly with very small changes in concentration.

2.4. Acidity and Alkalinity

Whether a solution is acidic or alkaline or likely to vary is of consequence to material selection. For this reason, the solution’s pH, or possible range of pH, needs to be specified.

2.5. Aeration

The degree of aeration of a solution can have a significant effect on its corrosiveness. Alloys that rely upon oxidation for passivity, Type 316 stainless steel for example, suffer severe corrosion in deaerated solutions. For alloys dependent upon a reducing environment for corrosion resistance, aeration of the solution can promote severe corrosion.

2.6. Solids

In low concentrations, often seemingly innocuous, solids suspended in the pumped liquid can cause corrosion-erosion. Frequently, the damage can be severe enough to result in premature, catastrophic failur...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Contributors to Volume 45

- Conversion to SI Units

- Bringing Costs up to Date

- Project Progress Management

- Project Scheduling

- Projecting Cost via Econometric Modeling

- Propane Recovery, Reflux-Exchange Process

- Propane Recovery, Ryan/Holmes Process

- Propane Refrigeration Systems

- Propylene Oxide and Glycol

- Propylene Refrigeration Systems

- Protein Engineering

- Pulp and Pulping

- Pulp Slurries, Density of

- Pulsation in Centrifugal Compressors

- Pulsation in Centrifugal Pumps

- Pulsation in Gas Metering Systems

- Pumice and Pumicite Supply-Demand Relationships

- Pumps