- 102 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Introduction to Unified Strength Theory

About this book

Strength theory deals with the yield or failure of materials under complex stress state. It is very important in mechanics of materials, strength of structures, and mechanical and civil engineering. Unified strength theory is a series of yield criteria and failure criteria other than a single strength theory. The unified strength theory can be adopted for various kinds of materials, such as metallic materials, geomaterials, polymers etc. It is the solution to the Voigt-Timoshenko Conundrum. Its limit surfaces cover all regions of the convex strength theory from the lower bound to the upper bound. This book gives a clear and brief description about the unified strength theory both in figures and text. Some applications of unified strength theory are also given in this book. This book is suitable for undergraduate students, who are studying the mechanics of materials and engineering mechanics, as well as for graduate students who are interested in this field. Researchers and engineers can also benefit from this book.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

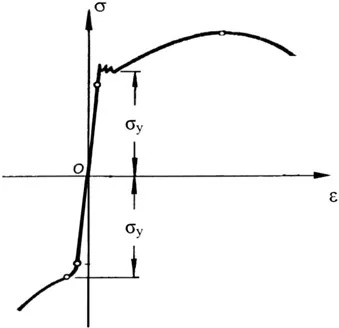

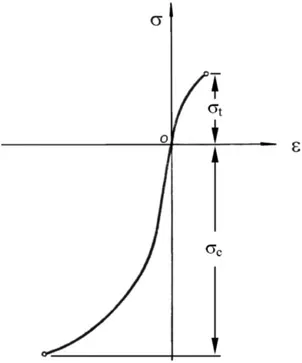

1.1 Strength of materials in tension and compression

1.2 Strength of materials under complex stress

| (1.1) |

| (1.2) |

| (1.3) |

1.3 Single strength theory

Maximum principal stress theory (Rankine criterion)

Table of contents

- Cover

- Half Title

- Title

- Copyright

- Contents

- Preface

- 1 Introduction

- 2 Stress state and elements

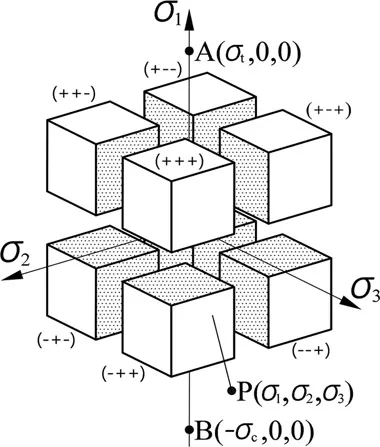

- 3 Yu-unified strength theory (Yu-UST)

- 4 Yu-unified yield criteria for metals

- 5 Applications of the Yu-UST and Yu-UYC

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app