Industrial engineering encompasses various technologies and production machineries that focus on high productivity and quality of fabricated goods. The main purpose underlying any industrial process is to strive for productivity and profitability. Industries use several mathematical models for productivity, which do not allow a production system to be described correctly. Exact mathematical models for the productivity rate include parameters such as technologies, design, reliability of machineries and management systems, which are the crucial problems in engineering. Modern manufacturing processes implement different machineries at preparatory, machining and assembly stages, where machining remains the most important one. Contemporary tendency of a manufacturing process is complication and automation of machines and systems, which is a natural result of engineering evolution. Production systems have become increasingly complex in design, which in turn are faced with reliability problems and is one of the most important attributes in all machineries and plays a key role in the cost-effectiveness of an industrial system. The productivity rate of machines and systems has a direct relationship with the reliability of their units, which should be described analytically. Analysis and mathematical modelling of machine productivity makes it possible to embed standard attributes of reliability as components of productivity rate equations for different designs and structures of industrial machines and systems.

1.1 Introduction

The term industrial engineering comprises a wide area of engineering that deals with the optimisation of complex processes and systems, and leads to eliminate wastage of production time, decrease machine time and decrease energy consumption and other resources that do not generate value. In addition, industrial engineers figure out how to better engineering processes and systems that improve quality and productivity. Industrial engineering encompasses a range of specialised fields of engineering, particularly areas of technologies and production machineries that focus on high output with high quality. This is a main part of economic activity of industrial companies that represents the critical success factor of production systems. To define optimal engineering solutions and to describe mathematical models for productivity of manufacturing machines and systems, the concepts involved in it are primary important problems in production systems.

The main purpose underlying any production process is to strive for productivity and profitability, which are typically specified concepts of efficiency. Production is a system of combining various technological processes, information, machinery and material inputs of production to manufacture products for consumption. All production systems are processes that transform resources into useful goods and are based on application of labour, equipment, materials, land, buildings, etc. The technological processes constitute the works in the preparatory, machining and assembly stages of manufacture, and finally the finished goods characterise a typical production system. The technological processes subject to the constraints of the capacity of the production system, which are limited by the nature of physics of technology and quality of products, limit the system’s ability to meet output expectations. The management of technological processes, i.e. the planning and control of the production system to achieve acceptable outputs, is an important task of the production manager.

The productivity of the manufacturing system and the quality of products are major factors in determining the efficiency of production systems. Some researchers have deliberated productivity as a phenomenon in production processes. They suggest that the measurement of productivity in production processes shall be developed so that it will indicate an increase or decrease in the productivity of the company. Researchers regard the measurement of productivity rate as an important part of the productivity phenomenon and solve the problems related to measuring it at a long time.

However, this approach is indistinct, indefinite, does not have links and does not give clear picture dependency of productivity on technological parameters of processes, design of manufacturing machine and systems.

In industries, there are several productivity measurement models. Finding an appropriate model for production systems is crucial and an important engineering and economic problem. First of all, it should be described as the main technological process of production systems, and after that study in detail must focus on the most interesting processes from the point of view of productivity and the solutions to measure such processes. Productivity should be identified in connection with profitability and then the processes and machinery-generating products.

Analysis of known models for evaluation of the productivity for production processes demonstrates that all of them consider productivity in terms of economics and far from engineering terms. Methodologies for calculating system productivity have been represented in several key publications that consider all aspects of the production process. For example, overall equipment effectiveness is a well-known concept in maintenance and is a way of measuring the effectiveness of a machine and systems. It is the backbone of many techniques employed in asset management programs. However, known models for productivity of different industrial machines and systems are represented by generalised equations and approaches in terms of economics, which do not allow one to discover all engineering properties of the production system. Real process of a company generates the production output, and mathematical models of the production processes can describe it. It refers to a series of components in production processes, which include parameters of technologies, design and reliability of machineries, management systems, that ensure the quantity and quality of products. Productivity index is a primary factor in economics that has two broad branches: macroeconomics and microeconomics.

Macroeconomics studies the economy as a whole. It also studies the country’s economy or the global economy and the economic decisions of a firm or groups of firms. In addition, macroeconomic problems are specific to an industry or a commodity. Macroeconomic productivity is a measure of the efficiency of production systems, where the term productivity is a ratio of the output to the input of labour or the amount of output per unit of input (labour, equipment, energy and capital). There are many different ways of measuring economic productivity. Productivity may be conceived of as a metric of the technical or engineering efficiency of production and might be measured based on the number of hours it takes to produce a good. Economists provide the definition of the efficiency of production as the ability to accomplish a job with minimum expenditure of time and effort. In addition, in economics, there are several partial mathematical models and definitions of productivity and efficiency for production systems. With the help of production function, it is possible to describe simply the mechanism of economic growth that presents a production increase achieved by an economic system. Economic growth is created by two factors: an increase in production input and an increase in production output. These components are represented mathematically by the following typical equation for the productivity of economic system [8]:

where L is the productivity economic system; M is the total number of manufactured products (output); Ce is the expenses for production processes (input); Cf is the fixed capital (cost of buildings, roads, lories, facilities, machinery, power station, computer centre, etc.); Cs is the service capital (cost of materials, energy, maintenance, cooling, water supply, etc.); S is the salary of employees, N is the service years for the economic system (factory, plant, industry, etc.); Q is the physical productivity rate of the economic system (products/year).

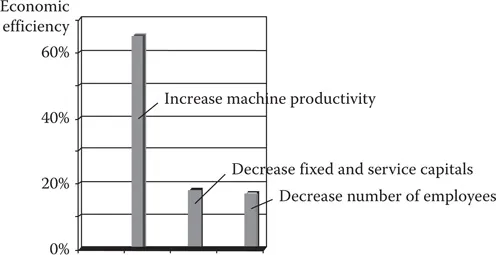

Economists analysed Eq. (1.1) and demonstrated how productivity of economic system depends on the value of its components and their influence on the economic system. Increase in the physical productivity Q gives 60%–70% of economic efficiency (automation and new technology), decrease in the fixed capital Cf and the service capital Cs gives 15%–20% of economic efficiency as quality of products, and decrease in the number of employees S gives 10%–15% of economic efficiency. Therefore, physical productivity is the main and weighed component in the efficiency of an economic system.

Growth potentials in productivity of economic system vary greatly by industry, and as a whole, they are directly proportionate to the engineering development in the branch. New and fast-developing industries attain stronger growth in the productivity of economic system. Developed industries demonstrate productivity growth in small steps. By the accurate measurement of productivity of economic system, it is possible to appreciate these small changes and create an organisation culture, where continuous improvement is a common value. Today, experts understand that human and social capitals together with competition have a significant impact on productivity growth. Figure 1.1 depicts the percentage of average impact of parameters for economic efficiency of production systems, i.e. increase in the physical or machine productivity, decrease in the fixed and service capitals and decrease in the number of employees.

Microeconomics studies the economic decisions of an individual firm or groups of firms. Microeconomics is considered mainly as the index of physical or machine productivity, where the term productivity refers to the ratio of the number of products fabricated per time. Engineering science (ASME) presents the term of productivity as the amount of work that can be accomplished in a given time period. The amount of work is represented as the number of products that can be discrete and continuous for production systems in the form of number of products, weights, length, volume, etc., which depends on the type of industries. Dimensions for physical or machine productivity represent the number of products/time, metre/time, litre or m3/time, kg/time, etc. Differences in productivity measurement models are made transparent and evaluated by clear technical units in productivity theory and can be used by the following economic models of productivity, which is the highest level of economics.

Physical productivity of machines and systems is important and is a multifactor index that depends on the technology of processes, the reliability of mechanisms, machines and units, and indices of managerial and organisational activities, which definitely affect the output of production systems. All these components can be represented in mathematical models for productivity rate of machines and systems. Manufacturers need the mathematical models for the productivity rate for different designs and complexity of industrial machines and systems. Such mathematical models should base on the reasonable links between all parameters that play an important role in development and evaluation of the production systems. In addition, these mathematical models should reflect changes in the production processes. It means mathematical models for productivity rate of industrial machines and systems are flexible tools that can give the ability in calculating the economic indices of production systems and take fast decision for micro and macroeconomics policies. Hence, the productivity theory for industrial machines and systems plays a primary role in the efficiency of the economic system.

The object of productivity t...