- 226 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

Human–Systems Integration: From Virtual to Tangible

Subject Guide: Ergonomics and Human Factors

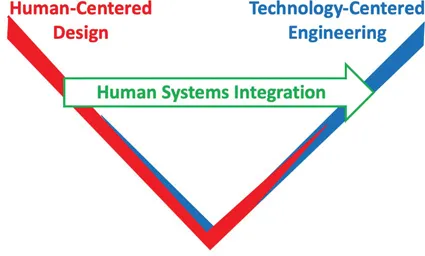

This book is an attempt to better formalize a systemic approach to human–systems integration (HSI). Good HSI is a matter of maturity… it takes time to mature. It takes time for a human being to become autonomous, and then mature! HSI is a matter of human–machine teaming, where human–machine cooperation and coordination are crucial. We cannot think engineering design without considering people and organizations that go with it. We also cannot think new technology, new organizations, and new jobs without considering change management.

More specifically, this book is a follow-up of previous contributions in human-centered design and practice in the development of virtual prototypes that requires progressive operational tangibility toward HSI. The book discusses flexibility in design and operations, tangibility of software-intensive systems, virtual human-centered design, increasingly autonomous complex systems, human factors and ergonomics of sociotechnical systems, systems integration, and changed management in digital organizations.

The book will be of interest to industry, academia, those involved with systems engineering, human factors, and the broader public.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

chapter one

Human-centered design of industrial complex systems

That’s what we do in real life, with puzzles that seem very hard. It’s much the same for shattered pots as for the cogs of great machines. Until you’ve seen some of the rest, you can’t make sense of any part.

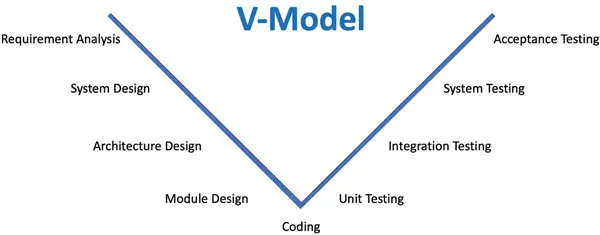

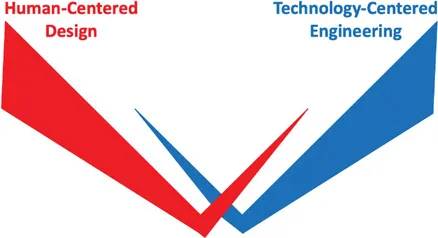

Technology-centered engineering versus human-centered design

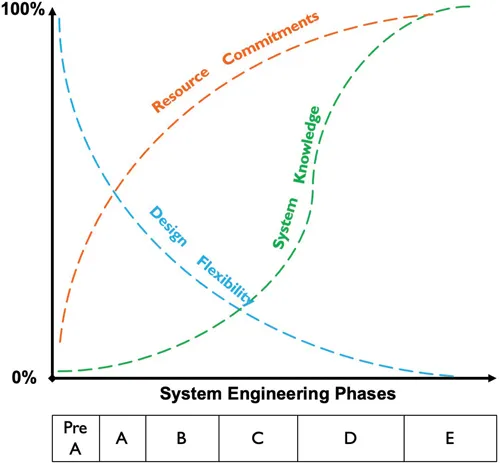

Impact of virtual HCD on the life cycle of a system

Pre-Phase A, Concept Studies | Feasible concepts, simulations, studies, models, mockups |

Phase A, Concept and Technology Development | Concept definition, simulations, analysis, models, trades |

Phase B, Preliminary Design and Technology Completion | Mockups, study results, specifications, interfaces, prototypes |

Phase C, Final Design and Fabrication | Detailed designs, fabrication, software development |

Phase D, System Assembly, Integration and Test, Launch | Operation-ready system with related enabling products |

Phases E and F | Operations and sustainment, closeout |

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Author

- Chapter 0 Introduction

- Chapter 1 Human-centered design of industrial complex systems

- Chapter 2 Tangibility problems and potential solutions

- Chapter 3 Technology, organizations, and people

- Chapter 4 Formalizing Human–Systems Integration

- Chapter 5 From rigid automation to flexible autonomy

- Chapter 6 Orchestrating Human–Systems Integration

- Chapter 7 Design for flexibility in an increasingly complex world

- Chapter 8 Activity, creativity, storytelling, and tangibility: The right mix

- Chapter 9 Evaluation processes and metrics

- Conclusion

- References

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app