![]()

1

Towards industrial and societal automation and digitisation

Jerker Delsing

Luleå University of Technology

CONTENTS

1.1 The need for new technology

1.2 From DCS and SCADA to Internet of Things and System of Systems

1.3 Automation system architectures

1.3.1 Automation system properties

1.3.2 Communication within automation systems

1.4 Current trends in automations systems

1.4.1 Production flexibility and customisation

1.4.2 Very large automation systems

1.4.3 Automation system security

1.4.4 Automation systems are physically local systems

1.4.5 Automation engineering

1.5 Future automation system requirements

1.6 Next generation automation and digitisation technology — IoT and SoS

1.6.1 Internet of Things — IoT

1.6.2 System of Systems — SoS

1.6.3 Service-Oriented Architecture — SOA

1.7 The local automation cloud approach

Bibliography

1.1 The need for new technology

High level topics in today’s society are sustainability, flexibility, efficiency, and competitiveness. These in turn are driven by big societal questions like environmental sustainability, availability of energy and other raw materials, and rapidly changing market trends. We find several trends that in different ways address these topics. One is the move from large monolithic organisations towards multi-stakeholder cooperations where cooperation is fostered by market requirements. Another is learning from previous products, other parts of the value chain, the life cycle of the product and the product or service production process itself.

These trends are putting new requirements on the technology used to support product and service production in todays society. This is why new approaches to production automation and stakeholder cooperation are sought by many players. It’s from these questions and requirements that the quest for digitisation of production is arising. Digesting this reveals a number of gaps regarding technology, organisation, cooperation structure, operational management, and related business models that have to be addressed.

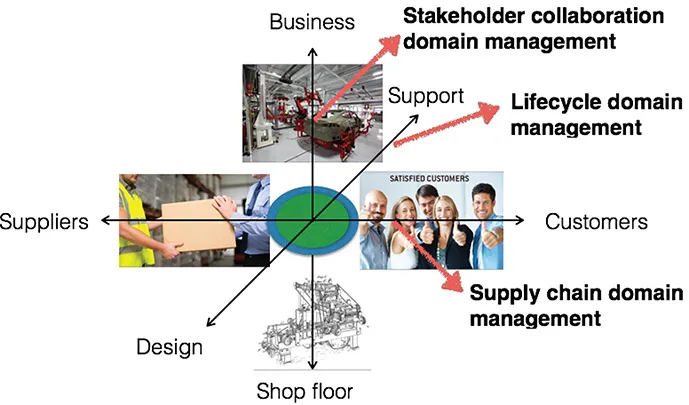

Around organisation, cooperation structure, and operational management high profile key aspects are related to three domains (see Figure 1.1):

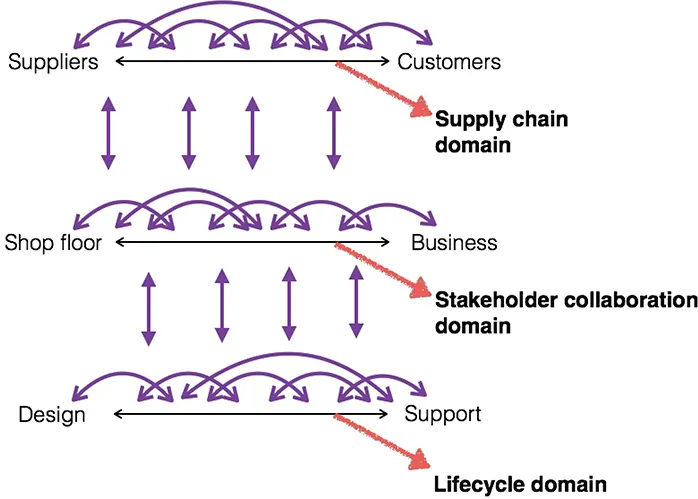

With the move from large monolithic enterprises towards multi-stakeholder cooperation, management is changing towards distributed multi-stakeholder collaboration with distributed responsibilities and decision making. The flexible collaboration along each of the three domains also opens the possibility of dynamic learning within each of the three domains (see Figure 1.2). A further aspect is that these domains tend to become wider (longer), involving more stakeholders with diverse objectives and more details and variations of the service or product to meet customer diversity and service and product quality.

These ideas are currently emerging but are regarded as very important to address the high level topics of flexibility, efficiency, and competitiveness and with suitable incentives also supporting sustainability.

To support these developments there are a number of technology gaps which seemingly cannot be addressed by the current state of the art. For this purpose, a number of new technologies are emerging to fill these gaps. Some current big buzz technologies are

Internet of Things, IoT,

System of Systems, SoS,

Cyber Physical Systems, CPS

Cloud

Big data

Service-Oriented Architecture, SOA

Despite all the new operational and organisational ideas and emerging technologies, the automation fundamentals captured by today’s state of the art automation technology have to be maintained. Thus the next generation of automation and digitalisation technology has to meet a large set of requirements while also involving a wider scope of actors and stakeholders. This is the big challenge for the automation and digitisation technology suppliers of the future.

Within the Arrowhead project [1] technologies addressing the capability of building large System of Systems based on IoT using an service-oriented approach has been in focus. The results have been tested in more than 20 real-world automation and digitisation use cases, resulting in a technology framework supporting some of the most prominent requirements to automation systems.

1.2 From DCS and SCADA to Internet of Things and System of Systems

Modern industrial production and manufacturing systems have evolved in basically four generations. The first generation that enabled the industrial revolution dates back to around 1850 or so. The use of steam-powered machines enabled mass production of goods such as clothes, cars, and many other products in the beginning of the 20th century.

In the second generation, the use of efficient pneumatic systems became a widely adopted solution for mass production. The combined use of pneumatic valves and sensors enabled automatic production systems to be used in industrial applications.

The third-generation systems evolved from pneumatic to electrical motors. The use of electricity as the energy source enabled even newer types of automatic control systems to be developed. Sensors and actuators were now connected to new types of monitoring and control systems like Distributed Control Systems (DCS) and Supervisory Control and Data Acquisition (SCADA) using technologies such as field buses. The hierarchical approach of device-level, DCS, and SCADA (known a ISA-95), soon became the defacto architectural style for how industrial productions systems were designed and deployed. DCS and SCADA systems soon became networked, which enabled tight integration between control systems and Enterprise Resource Planning Systems (ERP) and Manufacturing Execution System (MES), Today this is the most widely used approach by the industry, and has been so for at least the last 20-30 years. In the 1990s the current state of the art architecture ISA-95 was established [2]. Seemingly the size of ISA-95 based automation systems seems to be limited to approximately 100.000 I/O points. This becomes a technology bottleneck in the view of the upcoming smart cities and smart energy grids.

In 2011, the concept of Industry 4.0 [3] was born in Germany. This concept builds upon the last generation of industrial monitoring and control systems, but enables an even finer level of interaction between shop-floor devices and high-level enterprise systems. In Industry 4.0, state of the art technologies like the Internet of Things (IoT) and the Cyber-Physical Systems (CPS) are utilised in order to be able to break the classical strict hierarchical approach of ISA-95 [2] with a more flexible approach without barriers and closed systems. By basing all communication on standards-based protocols, like the TCP/IP protocol suite, it is now possible to have information exchange between (al-most) any systems in a production facility. This opens up the possibility for new strategies in terms of global plant optimisation, minimised energy consumption, safety and security, etc.

Of course, when more complex communications stacks are being deployed, even on resource-constrained sensors and actuators, new challenges and problems that must be handled are introduced [4]. One of the most critical challenges is security. When more and more devices are networked, it opens up vulnerabilities for remote network-based attacks. Earlier systems could only be configured by someone actually on the factory floor,...