- 256 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Corrosion Control Through Organic Coatings

About This Book

Corrosion Control Through Organic Coatings, Second Edition provides readers with useful knowledge of the practical aspects of corrosion protection with organic coatings and links this to ongoing research and development. Thoroughly updated and reorganized to reflect the latest advances, this new edition expands its coverage with new chapters on coating degradation, protective properties, coatings for submerged service, powder coatings, and chemical pretreatment. Maintaining its authoritative treatment of the subject, the book reviews such topics as corrosion-protective pigments, waterborne coatings, weathering, aging, and degradation of paint, and environmental impact of commonly used techniques including dry- and wet-abrasive blasting and hydrojetting. It also discusses theory and practice of accelerated testing of coatings to assist readers in developing more accurate tests and determine corrosion protection performance.

Frequently asked questions

Information

1 Introduction

1.1 SCOPE OF THE BOOK

- Composition of anticorrosion coatings

- Waterborne and powder coatings

- Blast cleaning and other heavy surface pretreatments

- Abrasive blasting and heavy metal contamination

- Weathering and aging of paint

- Degradation of paint by corrosion reactions

- Corrosion testing—background and theoretical considerations

- Corrosion testing—practice

1.2 TARGET GROUP DESCRIPTION

- Marine vessels and offshore installations

- Onshore and offshore pipelines

- Boxes and girders used under bridges or metal gratings used in the decks of bridges

- Penstock pipes in hydropower plants

- Tanks for chemical storage, potable water, or waste treatment

- Handrails for concrete steps in the fronts of buildings

- Masts for telecommunications antennas

- Power line pylons

- Beams in the roof and walls of food processing plants

- Grating and framework around processing equipment in paper mills

- Given a chance, the iron in them will turn to iron oxide.

- When the steel begins rusting, it cannot be pulled out of service and sent back to a factory for treatment.

1.3 COATED METAL SYSTEM

- A primer with metallic zinc particles. The function of the zinc is to provide cathodic protection. Being the first coat, the primer also provides adhesion to the substrate.

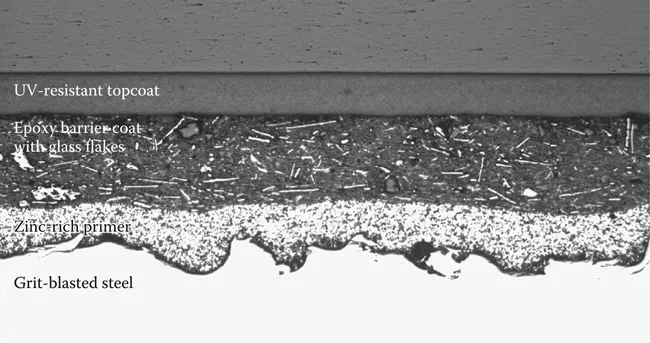

FIGURE 1.1 Blast-cleaned steel with a three-coat paint system—zinc-rich primer, barrier coat with flake-shaped pigments, and UV-resistant topcoat. The cross section image was taken with an electron microscope. A range of different qualities may be obtained by varying the pretreatment of the metal surface and the coating system (generic type, thickness, and number of coats).

FIGURE 1.1 Blast-cleaned steel with a three-coat paint system—zinc-rich primer, barrier coat with flake-shaped pigments, and UV-resistant topcoat. The cross section image was taken with an electron microscope. A range of different qualities may be obtained by varying the pretreatment of the metal surface and the coating system (generic type, thickness, and number of coats). - The intermediate coat is typically a barrier coating whose main action is to limit the transport of ions to the metal surface. The transport of oxygen and water is also limited.

- The topcoat is, if necessary, formulated to protect against degradation by ultraviolet (UV) light. In addition, the topcoat will give the required gloss, opacity, and color, that is, the visual appearance. It is also an additional barrier.

REFERENCES

2 Protection Mechanisms of Organic Coatings

- Stabilizing the passivating surface oxide

- Cathodic protection

- Passivating pigments

2.1 BARRIER AGAINST OXYGEN AND WATER

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- Preface

- Acknowledgments

- Authors

- Chapter 1 Introduction

- Chapter 2 Protection Mechanisms of Organic Coatings

- Chapter 3 Generic Types of Anticorrosion Coatings

- Chapter 4 Corrosion-Protective Pigments

- Chapter 5 Waterborne Coatings

- Chapter 6 Powder Coatings

- Chapter 7 Blast Cleaning and Other Heavy Surface Pretreatments

- Chapter 8 Abrasive Blasting and Heavy Metal Contamination

- Chapter 9 Chemical Surface Pretreatments

- Chapter 10 Adhesion and Barrier Properties of Protective Coatings

- Chapter 11 Weathering and Aging of Paint

- Chapter 12 Degradation of Paint by Corrosion

- Chapter 13 Duplex Coatings: Organic Coatings in Combination with Metal Coatings

- Chapter 14 Corrosion Testing: Background and Theoretical Considerations

- Chapter 15 Corrosion Testing: Practice