- 448 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Hip Replacement offers useful strategies to

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Topic

Medicine1

Alternate Bearing Surfaces in Hip Replacement

Orhun K. Muratoglu

Harvard Medical School, Massachusetts Institute of Technology, and Massachusetts General Hospital, Boston, Massachusetts

Harvard Medical School, Massachusetts Institute of Technology, and Massachusetts General Hospital, Boston, Massachusetts

Steven M. Kurtz

Exponent, Inc., Drexel University, and Thomas Jefferson University, Philadelphia, Pennsylvania

Exponent, Inc., Drexel University, and Thomas Jefferson University, Philadelphia, Pennsylvania

I. INTRODUCTION

During total hip arthroplasty, both the femoral and acetabular bearing surfaces are surgically replaced with metallic, polymeric, and/or ceramic components. Throughout the twentieth century, many different combinations of these materials have been explored as candidate bearing surfaces for total hip arthroplasty. Metal-on-metal total hip replacements were first implanted by Wiles in the 1930s (1) and later developed in the 1950s and 1960s by pioneering surgeons like McKee and Ring (2). In 1958, Charnley introduced a ‘‘low-friction arthroplasty’’ based on the principle of a metallic femoral component articulating against a polymeric acetabular component, and in 1970, Boutin developed the first ceramic-on-ceramic total hip replacement (Table 1). Charnley’s hard-on-soft bearing concept eventually dominated the other hard-on-hard bearing alternatives.

Today the most widely accepted bearing couple (i.e., combination of bearing materials for the hip joint) consists of a femoral head fabricated from cobalt chromium molybdenum (cobalt chrome or CoCr) alloy articulating against a polymeric component fabricated from ultrahigh molecular-weight polyethylene (UHMWPE). The use of the CoCr/UHMWPE bearing couple has provided consistent results in total hip arthroplasties around the world for the past four decades. In 1998, an estimated 1.4 million UHMWPE components were implanted worldwide, with approximately half of these bearings being implanted in the hip. Based on discussions with major orthopaedic manufacturers, at most 200,000 metal-on-metal or ceramic-on-ceramic components have been implanted in patients worldwide between 1988 and 2000, corresponding to less than 10% of total hip replacements during the same time period (3). Therefore, the overwhelming majority (over 90%) of total hip arthroplasties currently in service throughout the world include an UHMWPE or a modified UHMWPE component and are based upon Charnley’s original concept of hard-on-soft bearing.

Table 1 First-Generation Prostheses and Orthopedic Bearing Configurations

Despite the recognized success and worldwide acceptance of total hip arthroplasty, wear of the UHMWPE component is a major obstacle limiting the longevity of these reconstructions. In this type of a total hip replacement, which historically wears at an average rate of approximately 0.1 mm per year, it would take a century to erode through a 10-mm-thick UHMWPE component. However, at this wear rate, 100 million UHMWPE particles (assumed diameter of 1 µm) are liberated into the joint space on a daily basis. It is now well established that particulate debris generated from the articulating surfaces initiates a cascade of adverse tissue response leading to osteolysis and in certain cases loosening of the components (4–8). Extending the longevity of total joint replacements using alternative bearing technologies with improved wear behavior has been the subject of ongoing research in the orthopaedic community.

Since the 1970s, researchers have attempted to improve the tribological characteristics of UHMWPE by modifying the polymer’s structure, with the ultimate goal of improving the clinical performance of hip bearings. In the 1970s, carbon fiber–reinforced UHMWPE (Poly-II™) was clinically introduced for its potentially improved wear resistance (9), and a high-pressure recrystallized form of UHMWPE (Hylamer™) was clinically introduced in the 1980s for its improved creep resistance (9). Most recently, in the late 1990s, numerous research centers around the world confirmed that crosslinking of UHMWPE—whether by radiation, peroxide, or silane chemistry— can substantially improve the wear performance of the material in hip joint simulators (10–14). Based on these in vitro analyses, a number of radiation-crosslinked materials have been clinically introduced in the late 1990s.

A. Alternative Bearings for Long-Term Survivorship

Alternative bearings are needed not only to reduce the particulate debris burden and osteolysis but also to improve the survivorship of total joint replacements for younger and more active patients. Charnley originally intended total hip replacement primarily for patients who were disabled by rheumatoid arthritis and severe osteoarthritis (15). The surgery was initially restricted to patients over 65 and middle-aged patients were considered ‘‘occasionally’’ in the case of bilateral arthritis. Despite his restrictions on patient age (and indirectly activity level), Charnley predicted that neither surgeons nor engineers would ever make an artificial hip joint which would last 30 years and at some time in this period enable the patient to engage in athletic activities. However, today total joint arthroplasty is routinely performed on middle-aged patients, and both surgeons and engineers have recognized the need to assess the implications of a wide variety of patient activity levels on the outcome of the total joint arthroplasty. For example, in the UCLA Activity-Level Rating recently proposed by Zahiri and colleagues (16), the maximum score is assigned to patients who ‘‘regularly participate in impact sports, such as jogging, tennis, skiing, acrobatics, ballet, heavy labor, or backpacking.’’

In a recent review article describing the multiple factors that can influence wear in vivo, Schmalzried et al. (17) noted that ‘‘clinical rates of wear have traditionally been expressed with the use of time as the denominator. This has been done for reasons of convenience, not accuracy . . . the wear of a prosthetic hip is a function of use or the number of cycles, it is not simply a function of time.’’As a result of the difference in activity levels in young and elderly patients, it is not appropriate to compare the wear rates among studies with different patient demographics. Although age, coupled with diagnosis, is a significant predictor of (and surrogate for) activity level, research using pedometers to directly measure the number of steps taken by total hip replacement patients has shown a 40-fold variation in activity level among different patients (17). Therefore, ‘‘high demand’’ patients may be found in both younger and older candidates for total hip replacement.

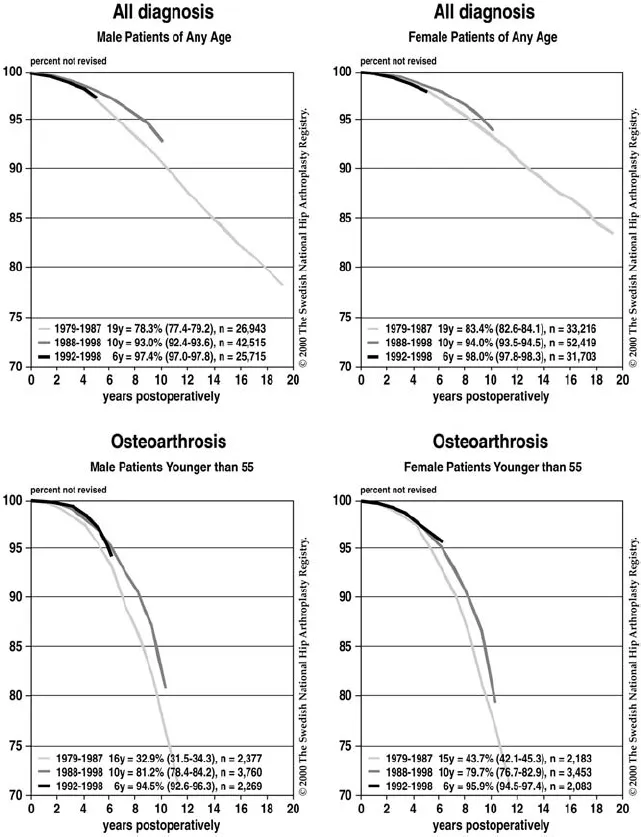

Even though the demands placed upon total joint replacements by patients have altered considerably since the introduction of the procedure, the aspirations for the longevity of the prosthesis have remained unchanged. Members of the orthopaedic community still strive to create an artificial hip joint that will last 30 years, even for middle-aged patients who want an active lifestyle. However, as recent outcome studies have shown (18,19), the long-term survivorship for total joint replacements decreases after 10 years of implantation. The most broad-based studies of total hip survivorship available in the literature have been conducted using the Swedish Total Hip Replacement Registry. Based on the most recent publication of findings, the register contains the records of 169,419 primary procedures and 13,561 revisions conducted between 1979 and 1998. The registry is used to track the long-term outcome for specific implants, surgeons, surgical centers, and patient groups across Sweden. Researchers have found that ‘‘the younger and more active patients are at greater risk [of revision] in all diagnostic groups. This is especially true for patients younger than 55 years of age’’ (19) (Figure 1).

Therefore, the young, active patient presents a challenge for the conventional CoCr/UHMWPE bearing couple in terms of extending the survivorship into the second decade of service, and most preferably into the third.

B. Overview of Biomaterials and Alternative Bearings

Alternative bearings are intended to significantly reduce or minimize wear at the articulating surface, thereby reducing the risk of debris-mediated bone loss and aseptic loosening. Four classes of bearing materials are discussed throughout this chapter: conventional UHMWPE, UHMWPE with elevated crosslink density (or ‘‘highly crosslinked’’ UHMWPE), CoCr alloys, and ceramics. These four categories of materials are not intended to comprise an exhaustive or all-inclusive list of potentially useful candidates for total hip replacements. A variety of coating and ion implantation technologies are currently under investigation for improved wear resistance in total hip replacements. For a detailed overview of coatings and ion implantation techniques in orthopaedic bearing materials, the reader is referred to a recent comprehensive review (20). However, the majority of these advanced coating materials technologies are still under development. Consequently, we focus our attention in this chapter on the four principal biomaterials used in the articulation of total hip replacements in terms of articulating couples: (a) the conventional articulating couple of CoCr/UHMWPE, (b) UHMWPE with elevated crosslink density articulating with CoCr or ceramic femoral heads, (c) ceramic on conventional UHMWPE and ceramic-on-ceramic articulations, and (d) metal-on-metal articulations. The first material, conventional UHMWPE, will be considered as the reference bearing material with the greatest clinical relevance due to its currently implanted patient base.

II. THE CoCr/UHMWPE ARTICULATION

This section focuses on the development of conventional UHMWPE as the bearing material of choice for total joint replacements.

A. Precursors to the CoCr/UHMWPE Articulation (Pre-1958)

The history of alternative bearings cannot be fully extricated from discussions of biological fixation and the problem of loosening at the bone/implant interface (Table 1). For example, bone-implant fixation was deliberately avoided in the Smith-Petersen mold arthroplasty developed during the 1920s, which were intended to facilitate bone-implant articulation at the femoral as well as acetabular sides of the component (21). By the 1950s, however, a different school of thought emerged in which bone-implant fixation was now considered an important surgical priority. In 1950, the Judet brothers introduced a hemiarthroplasty consisting of a polymethylmethacrylate ball fixed at the end of a short stem (22). Although these implants provided short-term pain relief, in Charnley’s view they ultimately failed after a few years due to a combination of high frictional torque at the articulating surface coupled with inadequate fixation between the short stem and the bone (15).

Figure 1 Survivorship of total hip arthroplasty as a function of age, based on the most recent report from the Swedish National Hip Registry. (From Ref. 19.)

B. The PTFE Era of Total Hip Replacement: 1958–1962

Charnley’s early experiments on joint function were directed at understanding the friction and lubrication of animal and artificial joints (23). Based primarily on a series of pendulum experiments, Charnley proposed in 1959 that polytetrafluoroethylene (PTFE) seemed ‘‘ideally suited’’ as a bearing material for total joint replacement because of its low coefficient of friction and biocompatibility in solid form (23). The chemical structure of PTFE is similar to that of UHMWPE with the exception that the pendant hydrogen atoms on the carbon backbone of the polymer molecule are replaced by flourine (PTFE belongs to the family of fluoropolymers). As a result, PTFE has a density of 2.2 g/cc, as opposed to 0.94 g/cc for UHMWPE. The fluorine atoms on the backbone of the molecular chain render the polymer highly resistant to chemical and thermal degradation.

The PTFE used by Charnley is often (and incorrectly) referred to in the orthopaedics literature as Teflon®, which is the trade name for a family of PTFE resins produced by DuPont (Wilmington, DE) in the United States. Charnley acetabular components were fabricated from Fluon resin produced by Imperial Chemical Industries (ICI) in Great Britain (24). When encountered in Charnley’s works, the terms Teflon, Fluon, and PTFE should be interpreted as synonymous (25).

Despite its excellent lubricity and satisfactory wear performance in vitro, PTFE exhibited two major disadvantages, which were discovered only after implantation in 300 patients (26). First, the PTFE exhibited elevated wear rates in vivo of up to 0.5 mm per month (27). Second, the PTFE wear debris elicited an ‘‘intense foreign-body reaction,’’ as Charnley elucidated by injecting two specimens of ‘‘finely divided’’ PTFE into his own thigh (25). Charnley also attempted to use glass-filled PTFE (under the trade name of Fluorosint) as a bearing material for total hip replacements, but despite promising in vitro test results, the composite also performed poorly...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Preface

- Contributors

- 1 Alternate Bearing Surfaces in Hip Replacement

- 2 Cementless Femoral Stem Design

- 3 Cemented Stems

- 4 Acetabular Component Design

- 5 Biological Fixation in Hip Replacement

- 6 Osteolysis in Total Hip Arthroplasty: Biological and Clinical Aspects

- 7 Revision Arthroplasty of the Acetabulum with Restoration of Bone Stock

- 8 Revision of the Femoral Component

- 9 Surface Arthroplasty of the Hip Revisited: Current Indications and Surgical Technique

- 10 Treatment of the Infected Total Hip Arthroplasty

- 11 Hip Arthroscopy

- 12 Computer-Assisted Orthopaedic Surgery for the Hip

- 13 A Five-Step Approach to Preoperative Planning in Total Hip Arthroplasty

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Hip Replacement by Raj K. Sinha in PDF and/or ePUB format, as well as other popular books in Medicine & Medical Theory, Practice & Reference. We have over one million books available in our catalogue for you to explore.