![]()

1

Introduction

What is wood pellet technology?

Wood pellets are a robust new fuel for space heating, hot water provision and, at a large scale, the generation of electrical power. They are a highly versatile wood-based product designed to compete with fossil fuels on convenience, performance and price. Overall, the technology encompasses production, supply and use of both wood pellet fuel and wood pellet combustion equipment.

The burgeoning 21st century wood pellet industry is led by Sweden, the USA and Canada, the latter alone producing round 1.3 million tons of pellet fuel in 2008. Europe produced around 9 million tons of pellets in 2007, led by Sweden and Austria. An innovative source of renewable energy, if the source is sustainably managed woodland or a clean waste wood, these small pellets are recognized as a virtually carbon-neutral fuel. Wood pellet technology has evolved rapidly since the early 1980s when it was first developed in Sweden as a practical and efficient way to use the timber industry's waste wood and the country's indigenous forest resource. Since then, the issue of climate change has reared its ugly head and wood pellets now provide a cost-effective, carbon-neutral and convenient alternative to fossil fuels such as coal and fuel oil for space heating and, increasingly, renewable electricity generation in the form of combined heat and power (CHP) where the power can be sold to the grid and the heat distributed to buildings and/or used as process heat.

Wood pellets are dryer and much denser than comparable fuels such as wood chips. This makes them free-flowing, easier to store and cheaper to transport. Their compact nature means they yield a relatively high heat. Similar in form to animal feed pellets – tubular, usually between 6mm (0.24 inches) and 12mm (0.47 inches) in diameter and 10–30mm (0.39–1.18 inches) long – they are usually tan to green-brown in colour, depending on the constituent material (see Figure 1.1). They are easy to ignite and produce both less ash and lower emissions than other wood fuel applications, and the ash they do produce is easy to handle. Their size and shape also allow for optimum air flow, which is important for maximizing heat outputs. Their small size enables loading via automated boiler-feed mechanisms. Some pellet space heating systems are so well automated that they need no human operator or maintenance beyond loading the winter store, pressing a button to start the system, then removal of ash six months later. This level of convenience competes well with that offered by oil and gas boiler systems.

Pellets themselves can, in theory, be made from a great many different organic and synthetic materials. Given this, ensuring quality control over the fuel stock's source, moisture content, admixtures and contamination levels is essential for the end-user and the industry as a whole. Only such guarantees will maintain confidence in the pellet product, assure the longevity of the combustion equipment and, of course, stimulate further demand from contented end-users and the good reputation earned by the technology. Most wood pellets are made from clean wood waste or clean forest sources such as sawmills, joinery factories and well-managed woodland thinnings. The supply of pellets to the end-user is already established in many regions of Europe and North America and at several levels. Handy 10kg (22 pound) bags can be picked up at some corner stores and petrol stations for domestic space heaters, while at the top end, big trucks deliver to larger end-users by blowing pellets down a tube straight into a fuel store; in Stockholm, boats are used to transport pellets to a CHP station.

Figure 1.1 Wood pellets

A guaranteed regular supply of quality-controlled pellets has been fundamental to the uptake of pellet combustion equipment. Dedicated stoves for room heating, boilers for larger spaces and even CHP pellet technology (see Chapter 4) have emerged in less than 30 years. Biomass co-firing is finding its place in large heat and power stations. The Netherlands burns pellets in a pulverized coal plant and similar developments are in their early stages in the USA. Space heaters and boilers on the market these days range from state-of-the-art, designer models to more basic and less expensive systems. Various levels of automation are available. Assuming quality control over feedstocks, three main factors give pellets an edge over other wood-based and carbon-neutral fuels: reliability in automated systems (even at a small scale); the lower cost of transportation; plus higher and more predictable heat outputs and a higher degree of temperature control.

Related technologies: log burning and wood chip

Of course, intentionally burning wood has a very long history. Homo erectus used it for warmth some 500,000 years ago and we Homo sapiens have used it for processes such as cooking and pottery making for around 10,000 years. Wood-fired underfloor heating was used by the Romans, Vikings and Anglo-Saxons. Before the fossil fuel age began in the early days of the industrial revolution, pretty well the entire human race depended on wood as its main source of heat. Water and wind power were developed to some degree, but wood was the dependable heavyweight source of energy until coal was taken up on a large scale during the 19th century. Now, as we approach the point of peak oil production and fossil fuel reserves are diminishing rapidly, the value of wood as a renewable fuel resource has been recognized once more. Not only do trees absorb carbon as they grow, but, managed properly, forests and woodlands are a theoretically endless source of wood.

Logs are the traditional way to use wood as a fuel. Today, there are scores of modern wood log stoves and boilers, many designed for pretty high efficiencies, low emissions and, compared to older stoves, much greater convenience of use. Apart from pellets, wood chips are the main alternative tree-derived fuel to logs. Medium to large boiler systems tend to use chips or pellets rather than logs, mainly because these forms of wood fuel are easier to use in fully automated systems. In domestic properties, or for single rooms, pellet technology is far superior to both wood chip and logs. Chip boilers don't work so well at this small scale. Logs take a lot of human handling, while pellets can be automated even at the smallest of scales.

The technology for burning logs has certainly improved over the millennia, but they are usually burnt in relatively simple ways: open fires, stoves, stoves with back boilers and dedicated boilers. Recent advances in boiler designs and controls have led to the manufacture of automated log boilers marketed for the larger house or small to medium commercial buildings. Generally, these boilers require stacking with logs just once a day. Workable automated log supply mechanisms would be very difficult to design and expensive to build, which is perhaps the main reason for the tendency towards using chips or pellets in larger installations.

Chip technology has advanced significantly further. Several large Scandinavian cities depend on wood chips for their heat and power, and some city centres in Finland even use chip-based heat to warm pedestrian pavements in downtown shopping streets to help avoid ice and snow underfoot. In the USA, pellets are more common at the small space heating stove level and, where they are compatible, in larger co-fired power stations. Space heating boilers, from small to large, are also being taken up at an increasing rate. The UK is a relative newcomer to wood chip heating, but it already has scores of schools and other local authority buildings enjoying the benefits of medium to large modern, automated wood chip boilers. Generally, though, wood chip combustion technology is designed for the upper end of the scale (wood chip boilers are available from about 30 kilowatts (kW), but are most reliable from about 200kW and over) – so unless you've got a really big house, large commercial building or a group of properties close together, you're better off looking at wood pellets or logs as an energy source. Wood chips flow well with automated boiler-feed mechanisms and most medium to large combustion units will cope with even relatively wet chip. Since wood chips rarely achieve lower than 25–40 per cent moisture content, this is a big advantage. In energy terms, pellets are presently more expensive than chips in Europe, with pellets at €10–13/gigajoule (GJ) and chips at €4–7/GJ.

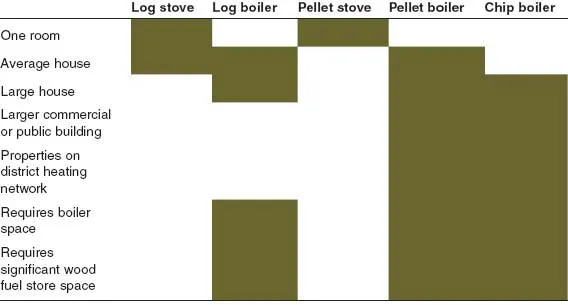

Table 1.1 Wood heating systems compared

Source: Dilwyn Jenkins; developed from an earlier version in the Wood Fuel in Wales booklet, Powys Energy Agency (2003)

However, in most automated boiler feeds, wood pellets flow even better than chips. Pellets are also much dryer and, by weight and volume, give off significantly more heat. In today's market place, pellets appear to be the most versatile of all wood-based fuels. They are appropriate to almost all requirements, regardless of ownership type (independent or cooperative) and building size. They're also the most convenient to handle and offer the greatest number of advantages when used in automated systems. For users with ready access to free or relatively inexpensive logs or wood chips, the versatility of pellets may not be a relevant factor. But for those who have to buy in fuel, wood pellets arguably provide the most effective and efficient technology. Table 1.1 compares the different types of wood heating system.

Examples of installed systems

Wood pellets are technically viable for most heating applications, so there's a wide range when it comes to the scale of systems already installed. For space heating in an average room, manufacturers – particularly in Austria and Finland – produce stylish and competitively priced room heaters. As with fossil fuel combustion the room heater and boiler systems described below – like all wood pellet installations, however small – require connection to an external flue or chimney.

Figure 1.2 Envirofire room heater (4–12kW)

Source: Coed Cymru

Pellet stove

Make: Envirofire

Output: 4–12kW

Cost: £1000 approx.

An Envirofire pellet stove was installed during 2000 by Coed Cymru, the non-governmental organization (NGO) dealing with woodlands in Wales, as a basic room heater in a large exposed office space in windy Mid Wales. With easy access to a range of dry wood matter and its own small-scale pelletizing machine, Coed Cymru did not have to buy in all its pellets. A single-skin flue was exposed for 5m (16 feet) within the room to maximize heat use. On an annual basis, its stove consumes around 650kg (1433 pounds) of pellet fuel at a rate of about 1kg (2 pounds) of pellets per hour. Maintenance requirements have proved simple, simply regular emptying of the firebox and the occasional emptying of the ash pan, plus removal of fly-ash that accumulates near the base of the flue. At the time of writing, the users reported that this stove has operated well for nine years. Their only real issue is that its output is too small for the large office space where it is installed.

Figure 1.3 Perhofer Biomat boiler (7–22kW)

Source: Pe...