eBook - ePub

Building Production Management Techniques

An Introduction through a Systems Approach

This is a test

- 192 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Building Production Management Techniques

An Introduction through a Systems Approach

Book details

Book preview

Table of contents

Citations

About This Book

Building Production Management Techniques provides an innovative approach to dealing with the universal problems of time, cost and quality of construction projects.

The book provides an introduction to a number of management techniques that can be applied to the problems of production presented by the diverse, heavy, large and geographically distributed products typical of construction everywhere. As well as recognised and tried and tested management techniques, the authors have introduced a number of techniques which may not have been considered by the construction industry to date.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Building Production Management Techniques by David R. Moore,Douglas J. Hague in PDF and/or ePUB format, as well as other popular books in Business & Service Industry. We have over one million books available in our catalogue for you to explore.

1 Introduction to systems thinking

Chapter objectives

• To introduce the key terms with regard to systems.

• To provide an overview of the two main perspectives on systems thinking.

• To show that a system has both an internal and an external environment, and interactions between them define whether the system is closed or open.

Definitions for key terms

Terminology is an important means of shorthand communication, but only so long as the person receiving the communication understands it to mean the same as the person sending it. For example; most people broadly understand that the word ‘roof has a variety of possible meanings. More specific information about the roof being discussed will be required before any production actions can be planned. Pitched roof and flat roof are two more specific forms of use for the word ‘roof’. However, it is frequently easier to accept this situation and use ‘roof’ rather than some other description such as ‘covering over the members which span across from the top of one wall of a structure to the top of an opposite wall’, or words to that effect. Having a common understanding of some key terms can make life a lot simpler.

Of all the definitions which may be required, perhaps the most difficult one to draw up is that for a construction industry. Everyone is generally aware that construction industries produce houses, factories and so on, but do they also know that they may include activities such as quarrying, erection of overhead power cables, etc? Whilst this definition of the industry can be a difficult one to produce it is also, in many ways, the least important one so far as the study of systems for production is concerned. So long as a production system itself can be identified and defined then it is of little importance if the system is producing cement or sherbet dips. That is not to say that the consumer of the product will display such a level of indifference: apparently cement does not tasie as good as sherbet dips! (Health warning: do not try to find out for yourself.) For the production manager dealing with the system however, the nature of that system itself is the important consideration.

A production system can be most easily defined by initially separating ‘production’ and ‘system’. Production can be defined as the intentional act of producing something useful. Accidents do not count as production. Irrespective of how useful the result may be, they remain accidents. Interpretation of the word ‘useful’ can be rather more of a problem, in that it can become laden with personal values. One person may think that a divider which provides sock sized compartments in a drawer is a very useful item indeed. Someone else may have their doubts about either socks or drawers being useful, never mind sock drawer dividers. Such values are of little relevance to the analysis of a production system. For the analyst, the problem relates to the intention to produce something, rather than the degree of usefulness which that something may possess.

Figure 1.1 Import, conversion, export activities forming a production system

Moving to the term ‘system’, this is perhaps the easiest term to define, but it can also be the most difficult to comprehend initially. Given that there is an intention to produce something, a Doofer, for example, there will also be a need for resources. Production of Doofers may require labour, machinery and materials. These resources are fed into the system where they undergo a process of conversion to become the product of that system: Doofers.

A system can therefore be defined as anything which involves inputs of resources, conversion of those resources, and the export of a product from the conversion. This can be summarised as I(mport) C(onversion) E(xport) or ICE, as shown in Fig. 1.1.

One useful aspect of this definition of a system is that it can also be applied to organisations (through organisation structures) as well as individual production systems, and will be dealt with in more detail in Chapter 5. As you read through the following chapters, you may come across terminology which you are unsure about. If so, you may want to have a look at the glossary of terms towards the end of the book. It does not contain all terms, but does deal with the more important ones.

Planning, analysis, control (PAC)

Having sorted out the basic definitions we can now move on to application. An important aspect of production is that it has to be planned (remember ‘intentional’?). Intention to produce something brings into play the requirement to produce it efficiently. Societies are generally becoming more concerned regarding the ethics of production, and construction industries are also becoming aware of the need not to squander finite resources. Combined with this is the straightforward business need to give the client, or purchaser of the product, value for money. This is increasingly being seen as different from supplying a product at the cheapest possible price. Construction industries have to consider quality as well as price.

Finally, there is the need to work within a certain time frame, or duration, for production. Clients for the construction product are all members of society and society has a range of demands which are put to construction industries in a variety of ways. All of these ways are basically seen as resulting in the production of different investment goods. General examples would be factories (enabling further production); additions to, or improvement of, a country’s infrastructure (roads, water supply etc.); investment which is classed as ‘social’ (hospitals, schools) and finally, as an investment good for direct enjoyment (housing) (Hillebrandt 1985).

Within such a diverse range of products there is at least one common factor: the purchaser, or client, is not willing to wait forever. Time must be viewed as being a resource which is as equally important as other resources of production. So, that nice, simple definition of a system (ICE) is now perhaps beginning to seem somewhat more complex. An ideal system has to be capable of turning out a product of acceptable quality, sufficient value for money and within a relevant duration whilst being able to demonstrate an ethical approach to resource utilisation. Not much to ask for really!

Acceptance of such criteria also denotes recognition of the need to work in a structured manner. Planning, which was briefly mentioned, is one important component of a structured method of working. To this can be added the components of analysis and control, which results in another handy acronym of PAC (planning, analysis, control). There is the possibility of an amusing mnemonic based around PAC(k)ICE and polar bears perhaps building up here, but let’s not get too ambitious just yet.

It is useful at this stage to develop some perception of the possible activities within each of the components of PAC. In order to do this, PAC’s use in the solution of problems that prevent an efficient process of production needs to be considered. Typical production problems which respond well to the systematic application of PAC are those falling into the following categories:

Work methods; quality control; equipment selection, maintenance and replacement.

All of these groups are relevant to production processes in construction industries. The planning of work methods, for example, is often seen as being relevant to productivity levels when considering buildability or constructability. However, the central element of PAC is analysis; the proposed solution to a production problem has to be analysed before it can confidently be implemented on-site. Analysis, however, is a large area to study and will only be dealt with in outline at this point. When attempting to carry out analysis, a structure has to be imposed. One way to do this is to split the analysis activity into subactivities, and work within those relevant to the production system to be analysed. Typical analysis subactivities are:

Human factors; work environment; methods and measurement; machines and maintenance; materials; systems synthesis.

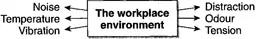

Figure 1.2 Interaction of human factors in the workplace environment

Of these subactivities, systems synthesis could be argued to be the most important one. This is because it allows the effects of system changes in other subactivities to be evaluated through the reuniting of individually analysed elements (a cause-to-effect process) of the planned system. It can also seem to be an awkward function to deal with. This is due to it being positioned within the analysis function, and yet it contains aspects of the planning, analysis and control functions. For example, synthesising an improved component back into a planned system may require further adjustments to be made to the system. Typical adjustments relate to the need for trade-offs which ensure that all elements are sufficiently compatible to form a coordinated system. This is the key purpose of systems synthesis.

The actions of analysis and synthesis are generally seen as being ‘lockstep’ stages in the development of a more effective (ultimately measured in terms of cost) production system. The meaning of ‘lockstep’ is discussed in more detail in Chapter 3. For now it can be considered in terms of the fact that within synthesis there is some degree of analysis. Briefly looking individually at areas of the analysis function gives some idea of the points to be considered in each of them:

Human factors

Generally seen as the most complex and unpredictable production factor, in an economic sense, within a production system. One example of analysis with regard to human factors is paying higher wages to attract and keep skilled workers compared against the cost of training and spoilage caused by employing less skilled workers. Typical considerations when analysing human factors are:

Human abilities; placement; training; motivation; safety and supervision.

Work environment

A secondary consideration to human factors. The workplace environment can affect the way human factors interact, see Fig. 1.2.

Workplace environment can affect motivation and safety in particular. It is important to note that performance in any production system is affected by the physical environment. Typical considerations about the workplace environment include:

Site location; facilities layout; workplace design; working conditions.

Methods and measurement

The design of the workplace can affect the work environment. In order to maximise the benefit of the design, methods and measurement are essential tools. They sho...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Acknowledgements

- 1 Introduction to systems thinking

- 2 Planning techniques for defining production systems

- 3 Analysis techniques for optimising production systems

- 4 Control techniques for implemented production systems

- 5 Designing an appropriate organisation structure for production

- 6 Conclusion

- References

- Recommended further reading

- Glossary of terms

- Self-test model answers

- Index