Introduction

THIS research was initiated at the University of Hawai῾i at Mānoa School of Architecture building in the summer of 2012. The objective was to undertake initial studies of bamboo properties, structural connections, gridshell layout and assembly, and gridshell erection. The work was defined as a preliminary study having the purpose of gaining a basic understanding of bamboo gridshell construction in preparation for the more extensive work planned for Vietnam. Seven students participated over the course of two months, meeting for three hours once or twice per week. The work was conducted on an exterior terrace of the building having a roughly triangular shape, with a dimension of about 9 m to a side. These dimensions were used as a design constraint for the overall size and shape of the gridshells produced.

Initial work involved harvesting bamboo for use in construction experiments. From our initial investigations it appeared that the number of sources where bamboo could be harvested locally was limited. Also, as this work was being conducted without funding, sources that were available at little to no cost were seen as advantageous. For the initial harvesting we were able to acquire bamboo from the City and County of Honolulu Board of Water Supply lands at no cost. We harvested approximately 60 canes of Phyllostachys vivax that averaged 6 m in length and that varied between 3.5 cm and 5 cm in outside diameter at the base of the cane and that were about 1.25 cm outside diameter at the tip.

Given that the constructions were experimental and temporary, no attempt was made to preserve the bamboo using any known treatment method. The bamboo canes were stored horizontally and air dried. The terrace used for the work faces south and west and receives significant sun exposure over the course of the day. As a result, the bamboo dried quickly over the course of several days. We elected to perform one informal test of a variation on the drying process. About 20 canes were selected, placed horizontally side-by-side between two supports, and weighted at the mid-span to bend them into a slight curvature. The canes were then sprayed with water periodically to slow down the drying process. The objective was to see if such an operation might stretch the fibers in the cane and provide greater flexibility in the dried member. We then compared the relative flexibility of this group of canes with the others. The comparison indicated that the 20 canes dried in this manner had somewhat greater flexibility than those that were allowed to air dry more quickly.

Structural connections

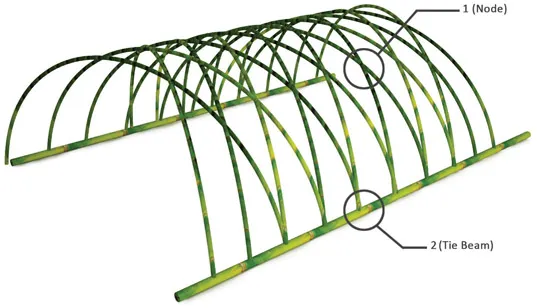

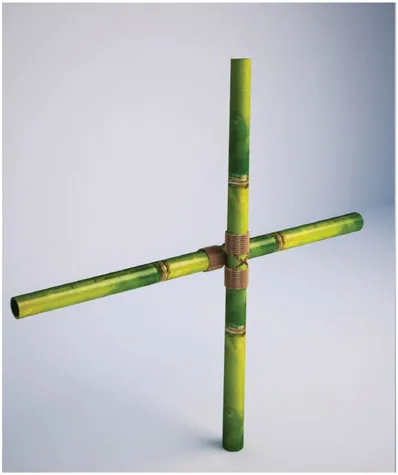

THE first investigations involved the construction of prototype connections between adjacent and overlapping gridshell bamboo structural members. Gridshells typically have only two types of connections: one is at the base where the spanning members connect to a tie beam; the other is where spanning members cross each other at node points [Figure 3.1]. For the purpose of exploring connections, a number of canes were cut to approximately 60 cm lengths. For each connection experiment, two canes were set in an abutting relationship disposed 90 degrees from each other [Figure 3.2]. After making a specific connection type, each was subjected to three informal tests: (1) pull test; (2) torsion test; (3) sliding test.

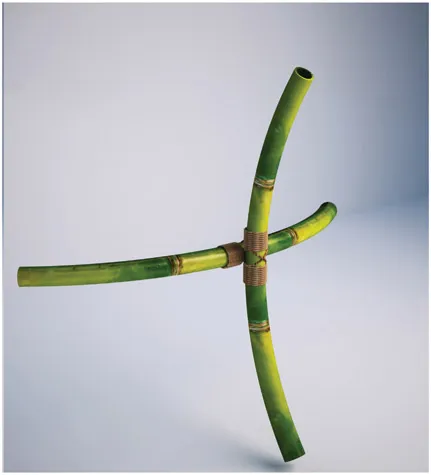

For the first test (pull test), the canes were pulled apart from each other in a direction normal to the cane surface [Figure 3.3]. The purpose of this test was to gauge the approximate resistance to loads that may be introduced normal to the gridshell surface curvature, as would be encountered with wind uplift forces. For the second test (torsion test), the canes were rotated relative to each other [Figure 3.4]. The purpose of this test was to gauge the approximate resistance to loads that may be introduced through lateral forces producing moments at the joint. As well, the degree of flexibility in rotation was noted. For the third test (sliding test), the canes were slid relative to each other [Figure 3.5]. As noted earlier, the structural connection between adjacent gridshell members must allow a degree of sliding and rotation to accommodate the change of geometry between the initial planar state of the gridshell net and its final curved form.

3.1 Shell connection conditions

3.2 Connection test configuration

3.4 Connection torsion test

3.5 Connection sliding test

Connection prototype 1 – Iron wire lashing [Figure 3.6]

BARE iron wire (0.75 mm diameter) was wrapped in a manner approximating a typical lashing pattern to fix the canes to each other. Given that the wire is quite malleable, the winding operation by hand is relatively easy and quick. The wires were twisted together to fasten the ends. The twisting method is fast and serves to allow tightening as needed. Since this method follows lashing patterns, a number of variations are possible, such as the number of windings, number of diagonal windings vs. parallel windings, and so forth. Each variation would appear to produce slightly different results, with the expected increase in sliding, rotation, and pullout resistance afforded by the increase in winding and wire used.

However, it should be noted that a determination was made initially as regards the application and use of iron wire. Iron wire is highly vulnerable to rust, and this fact, along with its relatively small diameter, would indicate that the wire would likely fail after a short period in any typical exposed condition. For this reason, this method was judged to be potentially useful only as a temporary connection to be used for initial construction operations. Also of note was the care needed in handling the wire as the sharp exposed ends can easily cut unprotected skin.

Tests 1–3 indicated sufficient strength and flexibility for application in initial construction operations.

3.6 Iron wire lashing connection

Connection prototype 2 – Zip tie connection [Figure 3.7]

ZIP ties are most commonly used for bundling electrical cords or wires, but can be used to bind other types of elements together. Because of the wide range of applications, zip ties are produced in a variety of sizes (strap length, width, and height), materials (e.g., nylon, ABS [acrylonitrile butadiene styrene], stainless steel), and strengths (tension pullout resistance). For the first test only one type of zip tie was used. This was a nylon strap 40 cm × 0.5 cm × 0.2 cm, rated at 40 kg. The primary advantage of zip ties is the speed at which a connection operation can be completed.

For the test, a simple connection was made using three zip ties. Two ties were fastened on opposed diagonals, and the third was wound parallel to the cane length between the canes to tighten the diagonal ties. Further tests could be conducted using additional ties. However, a determination was made initially that like the iron wire, the zip ties were most likely useful only as a temporary connection. Plastic ties are available with ultraviolet (UV) resistant additives; however, it was determined that even with such additives, the useful life of the tie would be limited in a typical exposed condition. Also, while the zip tie used was rated at 40 kg pullout strength, the actual strength appeared to be much lower and was judged likely to fail in anticipated uplift or moment loading conditions.

Tests 1–3 indicated sufficient strength and flexibility for application in initial construction operations.

Given the speed of assembly that zip tie use affords, further investigation is warranted, particularly with the use of higher-strength plastic or stainless steel types. Stainless steel types should perform well in exposed conditions; they are available with higher strength ratings and therefore appear promising as a permanent connection means. However, one caveat is worth noting: in order to maximize the speed advantage of zip ties, a minimum number should be used, and as such the bearing area on the bamboo canes is reduced over other methods, such as conventional lashing. Therefore it is possible that under higher loads, joint failure would occur by buckling or splitting of one or both canes. Point loads in such a case could be distributed using a wrap between the cane and the zip tie; however, this adds another step to the assembly operation.

Connection prototype 3 – Tape connection [Figure 3.8]

POLYPROPYLENE reinforced strapping tape (3M Scotch brand, 18 mm wide, 2700 N/100 mm tensile strength) was wrapped around the canes in a manner approximating conventional lashing. The application of tape to accomplish a connection is relatively fast and is comparable to the aforementioned wire and zip tie methods. The adhesion of the tape to the cane surface helps to provide a reasonably secure fastening. Unfortunately, the adhesion does not provide sufficient sliding flexibility needed in initial construction operations. It would be possible to add a sleeve between the tape and the cane to break the adhesion and allow sliding. However, no tests were conducted of this method. The performance of the tape in exposed conditions over time is suspect and requires further investigation should it be proposed for use as a permanent connection.

Tests 1–3 indicated sufficient strength and flexibility (torsion) for application in initial construction operations, but the flexibility in sliding is limited, thereby reducing its range of application.

Connection prototype 4 – Conventional lashing [Figure 3.9]

JUTE twine (2 mm +/– diameter) was wound around the canes in a conventional manner, with windings diagonal and perpendicular to the cane length and parallel between canes to tighten and cinch the joint. Conventional lashing is the predominant method used historically and has a number of variations. Certainly one advantage of this method is its ability to adapt to size, strength, flexibility, bearing area, and other requirements as may be called for in any given connection. A degree of care and skill is required to accomplish a balanced lashed joint (appropriate numbers and types of windings) and one that is reasonably snug.

Tests 1–3 indicated sufficient strength and flexibility for application in initial construction operations. As well, the connection could be used as a permanent joint given its strength, ability to be tailored to the joint condition, and ability to withstand a degree of weather exposure.

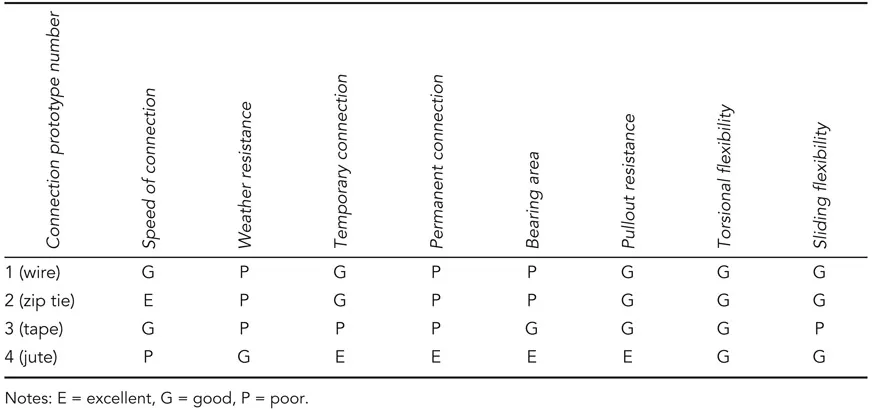

TABLE 3.1 lists the salient characteristics of each connection prototype and shows a subjective value (excellent, good, poor).

Table 3.1 Subjective connection types evaluation