eBook - ePub

Foam Patterning and Construction Techniques

Turning 2D Designs into 3D Shapes

- 224 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Foam Patterning and Construction Techniques: Turning 2D Designs into 3D Shapes explains how to create your theatrical prop, puppet, or costume design using the unique and tricky medium of foam. Step-by-step instructions, photographs, and explanations illustrate how to translate your design from paper to reality by creating custom "skin" patterns, followed by creation of a foam mockup. The book details how to bring your project to life with varied finishing techniques, including using fur and fabric coverings and dying and painting foam. Numerous supplies, tools, and safety procedures and protocols are also covered.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

SECTION I

THE MEDIUM OF FOAM: MATERIALS, TOOLS, AND SAFETY

chapter one

materials: foams, tools for shaping, cutting surfaces, and adhesives

This chapter provides an overview of foams and some of the items used for shaping and patterning.

Foam

There are many different varieties of foams. Whether it is for structure, flexibility, or mold ability, each foam is produced and developed for a specific use. With a little artistic planning and experimentation, foam has been and can continue to be adapted and used for many nontraditional projects that utilize the same properties.

The discovery and/or development of the basic ingredients (isocyanates, polymeric polyols, styrols, isobutylene, etc.) for the manufacturing of almost all plastics and foams are a result of the petrochemical and coal industries. There are a few exceptions to this wherein a discovery of a substance or chemical was made as a result of experimentation with living plants or animals. For the most part these early endeavors were expanded upon and modified using contemporary technology. Now there are an abundance of foams used for everything from packaging and soundproofing, to floatation and food handling.

Many of these foams do not degrade quickly and can last for hundreds of years in landfills. Foams and their additives are also becoming more integrated into our soil and water. Fortunately there have been successful efforts in reducing the toxicity levels of foam additives; lowering VOC (volatile organic compound) levels and creating foams that are biodegradable made from vegetable oils and starches such as soy and corn.

How Foam is Made

The most basic explanation of how foam is produced is that liquid base A and liquid foaming agent B are combined. While the foaming agent reacts and produces air pockets expanding the mass of the mixture, this produces heat, called an exothermic reaction. When the mixture has reached its maximum expansion, it cures becoming soft or rigid, and foam is produced. Chemical variations in the base and the foaming agent will produce a variety of textures, pore sizes, flexibilities, and densities. When beginning to build up a knowledge of different foams, it is important to be able to touch and handle all the varieties available. When ordering online, try to get samples to familiarize yourself with various products. This will help you to know what type of foam might be best for any future applications.

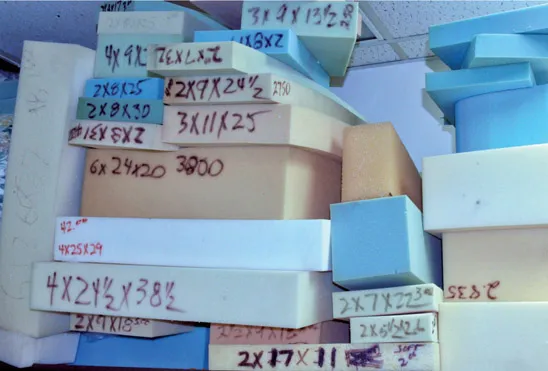

When prefabricated at foam manufacturers, liquid batches of some types of foams are mixed in large vats and poured into molds. When the foam is fully expanded and cured in block form, it is called a bun. The bun is cut to the desired widths (planks, profiles, sheets) by using tools such as a large horizontal band saw, a precision laser, or a cutting machine using a water jet. Depending on the type of flexible foam and where you buy it, commercial thicknesses can range from 1/4 inch and up. Rigid foams such as expanded polystyrene foams can be purchased in huge blocks and slabs. If you go to a manufacturer where foam is made, it is sometimes also possible to have custom thicknesses cut for the needs of the project.

Types of Flexible Foam

- Closed-cell foam—Closed-cell, mini-cell, cross-linked polyethylene, fun foam, L 200: all of these are names for lightweight foam that is great for carving, sanding, and constructing. It is very dense, allows for little to no water absorption, but is soft. The flexibility can vary depending on the thickness and density. This foam paints really well with a brush or an airbrush. Thin widths of closed-cell foam (1/8 inch to 1/4 inch) can be shaped using a hot hair dryer without scorching or melting. L 400 and L 600 are denser varieties of this foam—the greater the number the more dense and structural the foam. The 1/2-inch thick, gray, anti-fatigue mats are a popular and very accessible type of mini-cell foam which can be purchased at stores such as Harbor Freight and Lowes.

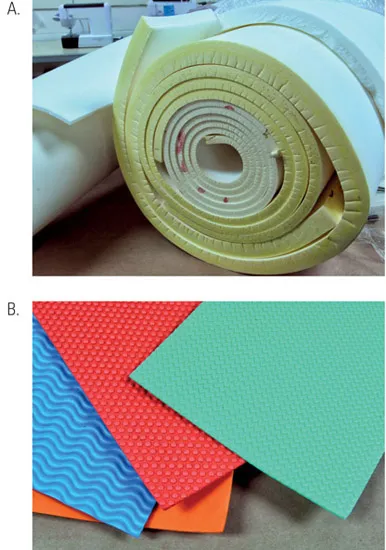

Figure 1-1:

A. Closed-cell foam also called L 200, mini-cell, and generically, cross-linked polyethylene foam (depending on the manufacturer).

B. Mini-cell foam can be purchased in 1/8-inch sheets, called fun foam, in many colors and textures.

A. Closed-cell foam also called L 200, mini-cell, and generically, cross-linked polyethylene foam (depending on the manufacturer).

B. Mini-cell foam can be purchased in 1/8-inch sheets, called fun foam, in many colors and textures.

- Open-cell foam—Developed in the 1940s, liquid urethane was first used for coatings on airplanes. It was discovered that the addition of polyols would expand and form a porous material. These first foams were used for floatation and insulation. Urethane foams are now used for everything from filtration and soundproofing to packaging, large-scale industrial fabrication, and special effects.

Figure 1-2: Polyether foam, also called upholstery foam, comes in a variety of colors and widths. The color variations can represent different densities (firmness) and longevity.

- Polyether urethane foam—When inquiring about polyether foam it might be referred to as: urethane ether foam, urethane foam, craft foam, or upholstery foam. This foam is very soft, has small pores, and is flexible. It can be carved, sanded (using a belt sander), glued, patterned into shapes, dyed (test to make certain), and airbrushed. Due to its chemical composition it is somewhat fragile and is not suited for hand sewing without reinforcement or for machine sewing. It is also not as durable as polyester (reticulated foams). It will eventually disintegrate when exposed to sunlight and moisture; however, if covered with fabric (as with furniture upholstery or covering a foam puppet), it may last for many years depending on the amount of use. It is readily available and can be found in local craft and fabric stores as well as those businesses specializing in upholstery.

Though prices have risen considerably, polyether urethane foam is cheaper than most other foams and easier to find. Polyether foam is my first choice for building mock-ups of newly patterned shapes. There are many different grades varying from a slightly crisper, low cost, less durable foam to a softer, denser, and more durable variety found in green, blue, and white.

Figure 1-3: Notice the small pore size of polyether foam.

Figure 1-4: Tiger head in mini-cell foam and a mock-up in less expensive upholstery foam.

- Polyester urethane foam—Also known as reticulated foam, scot foam, or filtration foam, polyester urethane foam is very durable, flexible, paintable, dye-able and, depending on the height of the machine presser foot, it can be sewn on a machine or by hand (if using a commercial machine, 1/4 to 1 inch is the maximum suggested width). It comes in white or black. The ppi (pores per square inch) can vary affecting the surface look of the piece. Though every foam crafter h...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication Page

- contents

- Acknowledgments

- Preface

- Section I The Medium of Foam: Materials, Tools, and Safety

- Section II Design

- Section III Translating Design into Reality: Techniques used in the Patterning Process

- Section IV Determining the Pattern Divisions, “Truing” Patterns, and Changing Scale

- Section V Putting it all together: From Pattern to Object

- Section VI Finishing the Design

- Section VII This Section goes through the Full Process for Six Projects

- appendices

- index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Foam Patterning and Construction Techniques by Mary McClung in PDF and/or ePUB format, as well as other popular books in Mezzi di comunicazione e arti performative & Teatro. We have over one million books available in our catalogue for you to explore.